Method for separating and recycling protein in bean curd yellow pulp water using membrane

A technology for separation of yellow pulp and water by membrane, applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve the problems of reduced protein retention rate, only compromise, low protein retention rate, etc., and achieve oligomerization The effect of high sugar transmission rate, convenient operation and high protein recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

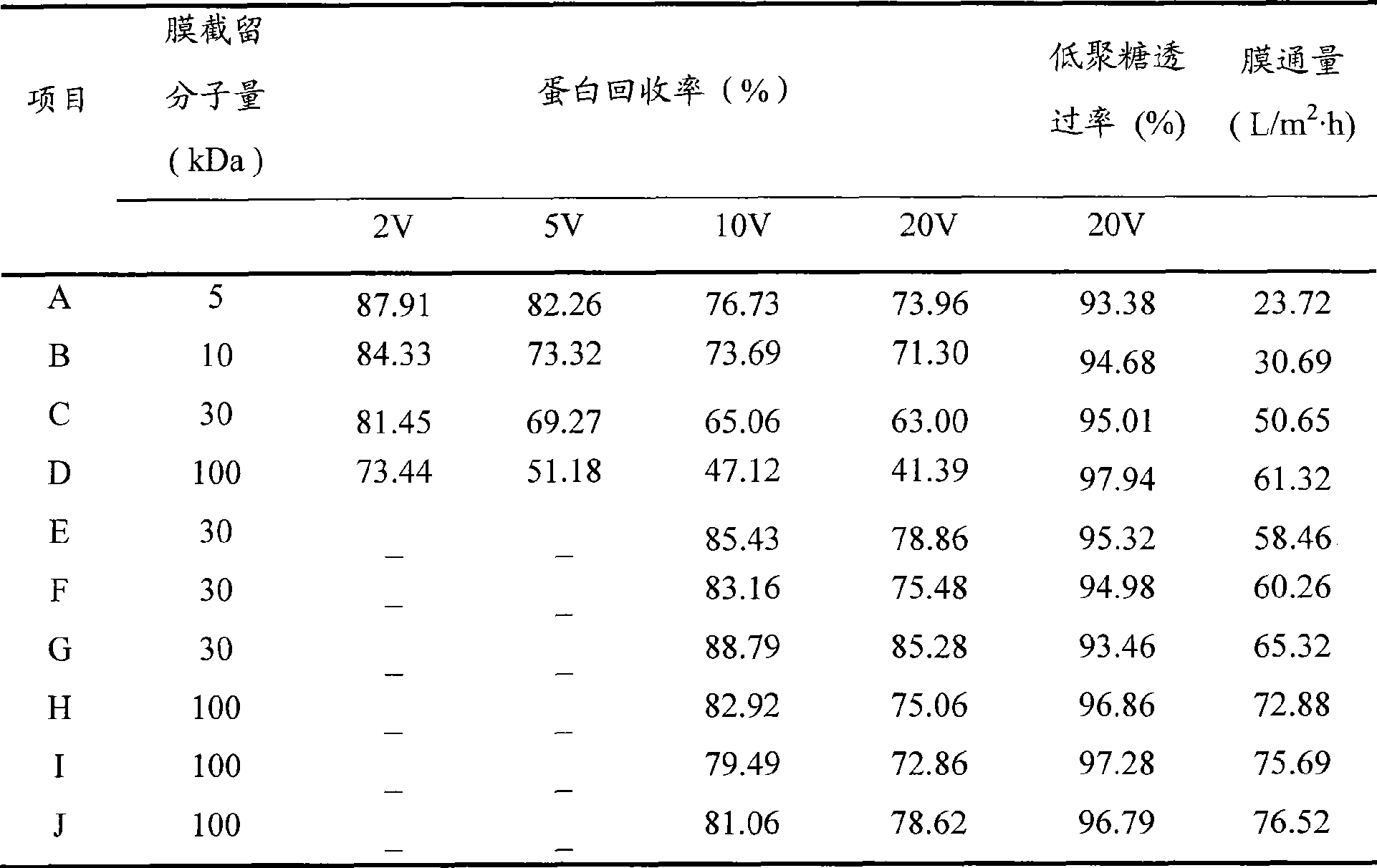

[0015] 500mL tofu yellow syrup water (protein content 3mg / mL, total sugar content 32mg / mL), add to the Millipore cup ultrafiltration ultrafiltration at room temperature, the ultrafiltration membrane is polysulfone membrane, the molecular weight cut-off is 5kDa, the inlet pressure is 10PSI, the outlet Pressure, 15PSI, injection flow rate 2mL / min. For each concentration 2 times (volume) (that is, the volume of the original solution is twice the volume of the resulting concentrated solution, marked as 2V in Table 1), 5 times (ie the volume of the original solution is the volume of the resulting concentrated solution 5 times the volume, marked as 5V in Table 1), 10 times (that is, the volume of the stock solution is 10 times the volume of the resulting concentrated solution, marked as 10V in Table 1), 20 times (that is, the volume of the stock solution is 20 times the volume of the resulting concentrated solution, (Marked as 20V in Table 1), take the concentrate and the permeate respe...

Embodiment 2

[0017] 500mL tofu yellow syrup water (protein content 3mg / mL, total sugar content 32mg / mL), add to Millipore cup ultrafiltration ultrafiltration at room temperature, ultrafiltration membrane is polysulfone membrane, molecular weight cut-off is 10kDa, inlet pressure is 10PSI, outlet Pressure, 15PSI, injection flow rate 2mL / min. For each concentration 2 times (volume), 5 times, 10 times, 20 times, take the concentrate and the permeate respectively, record the time, detect the protein and oligosaccharide content, and calculate the protein The rejection rate, oligosaccharide permeability and membrane flux are listed in Table 1 (B).

Embodiment 3

[0019] 500mL tofu yellow syrup water (protein content 3mg / mL, total sugar content 32mg / mL), add to the Millipore cup ultrafiltration ultrafiltration at room temperature, the ultrafiltration membrane is a polysulfone membrane, the molecular weight cut-off is 30kDa, the inlet pressure is 10PSI, the outlet Pressure, 15PSI, injection flow rate 2mL / min. For each concentration 2 times (volume), 5 times, 10 times, 20 times, take the concentrate and the permeate respectively, record the time, detect the protein and oligosaccharide content, and calculate the protein The rejection rate, permeability of oligosaccharides and membrane flux are listed in Table 1 (C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com