Preparation of coating type cerium oxide / silicon oxide compound abrasive

A composite abrasive, silicon oxide technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem that the cerium oxide/silicon oxide composite powder cannot be completely obtained, and the coating amount of cerium oxide particles cannot be easily controlled. Insufficiently uniform particle coating and other problems, to achieve the effect of improving polishing surface quality, reducing polishing passes, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

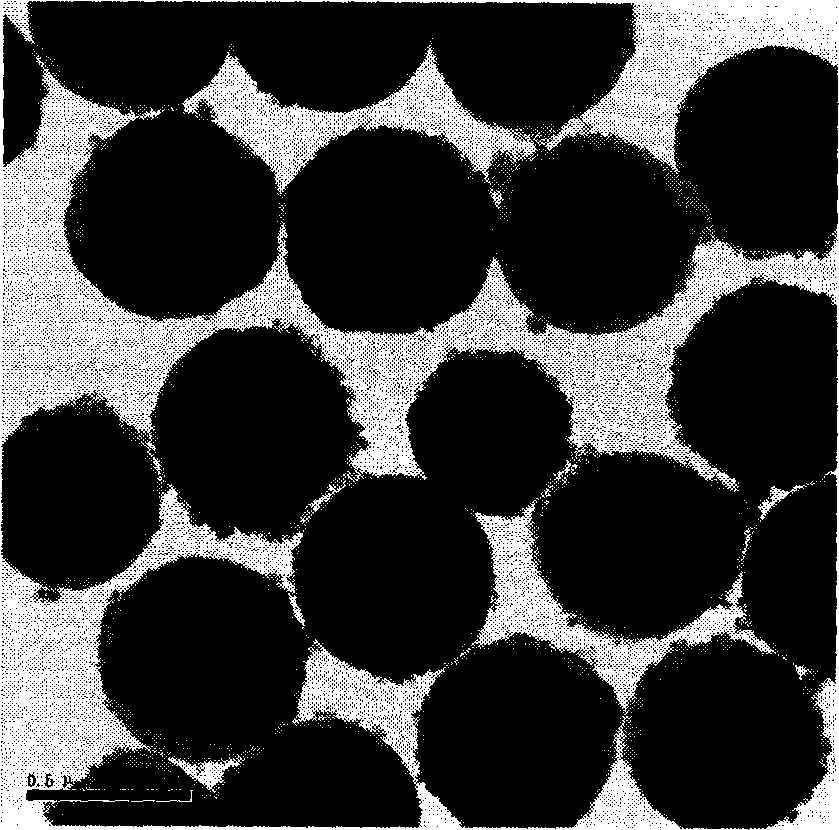

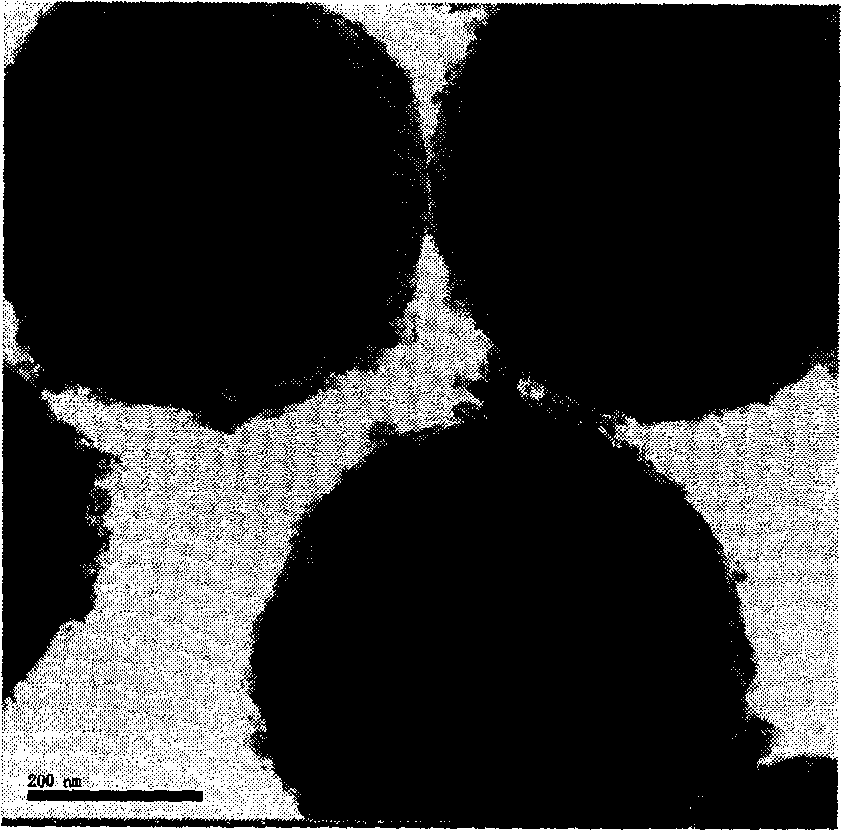

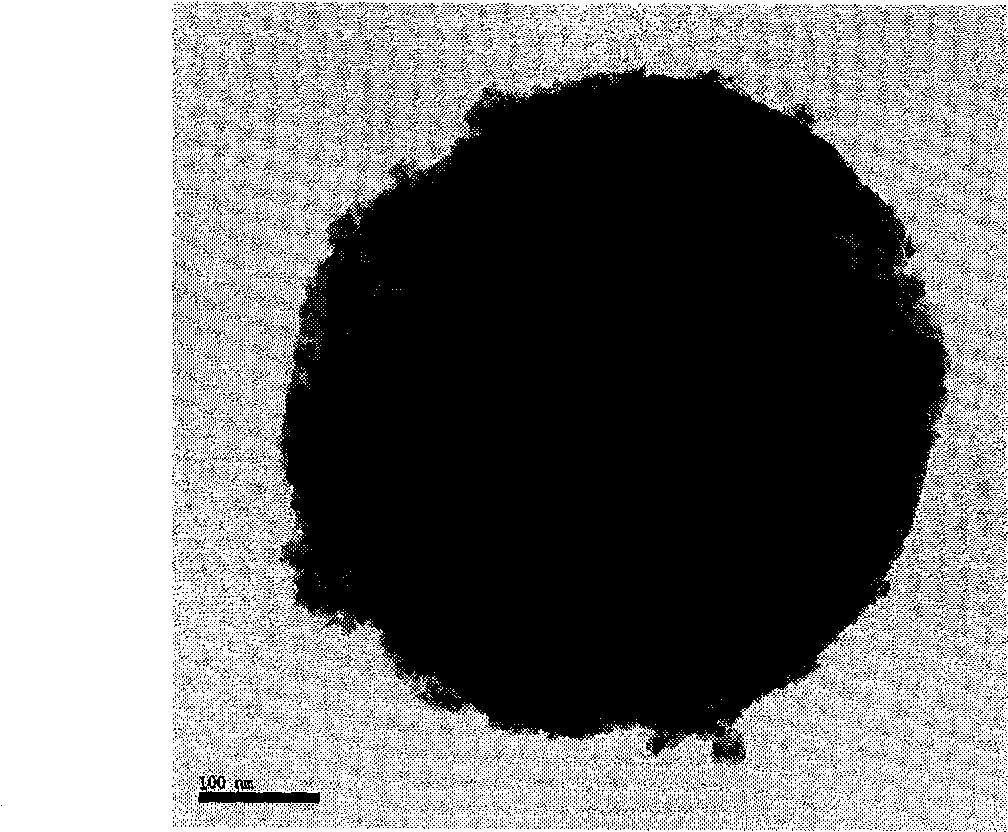

[0018] Embodiment 1: Take by weighing cerous nitrate hexahydrate 0.05M, be dissolved in the n-propanol / deionized water mixed solution containing n-propanol 0.1M and deionized water 0.1M, add the acetylacetone of 29ml again, at room temperature Electromagnetic stirring was performed for 24 hours to prepare a transparent and clear bright yellow cerium sol with a cerium ion concentration of 1.0 mol / l. Then weighed 400nm monodisperse spherical SiO 2 1g of powder is immersed in 15ml of cerium sol under the conditions of ultrasonic and mechanical stirring, and the dispersion of silicon oxide microspheres is strengthened by ultrasonic and mechanical stirring, and then it is left to stand for 10 minutes, and the surface of the silicon oxide powder coated with cerium sol Centrifuge, dry and grind in a blast oven at 70°C, and then calcined at 500°C for 1 hour to obtain coated cerium oxide / silicon oxide composite abrasive. The phase structure of the obtained samples was characterized by...

Embodiment 2

[0020] Example 2: The steps of this example are basically the same as those of the above-mentioned Example 1, the difference is that a cerium sol with a cerium ion concentration of 0.2 mol / l is prepared, and then the silicon oxide powder coated with the cerium sol is calcined at 300°C 0.5h. Subsequent detection was as in Example 1.

Embodiment 3

[0021]Embodiment 3: the steps of this embodiment and above-mentioned embodiment 1 are basically the same, and difference is: change chelating agent to be citric acid, prepare the cerium sol that cerium ion concentration is 2mol / l, then the silicon oxide of surface coating cerium sol The powder was calcined at 600°C for 4h. Subsequent detection was as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com