Antiradiation pressure sensor

A pressure sensor, anti-radiation technology, applied in instruments, fluid pressure measurement by changing ohmic resistance, measuring devices, etc., can solve the problems of decreased insulation performance, weakened isolation effect, performance degradation, etc., to improve and weaken the anti-radiation ability. The effect of radiation intensity and geometric area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

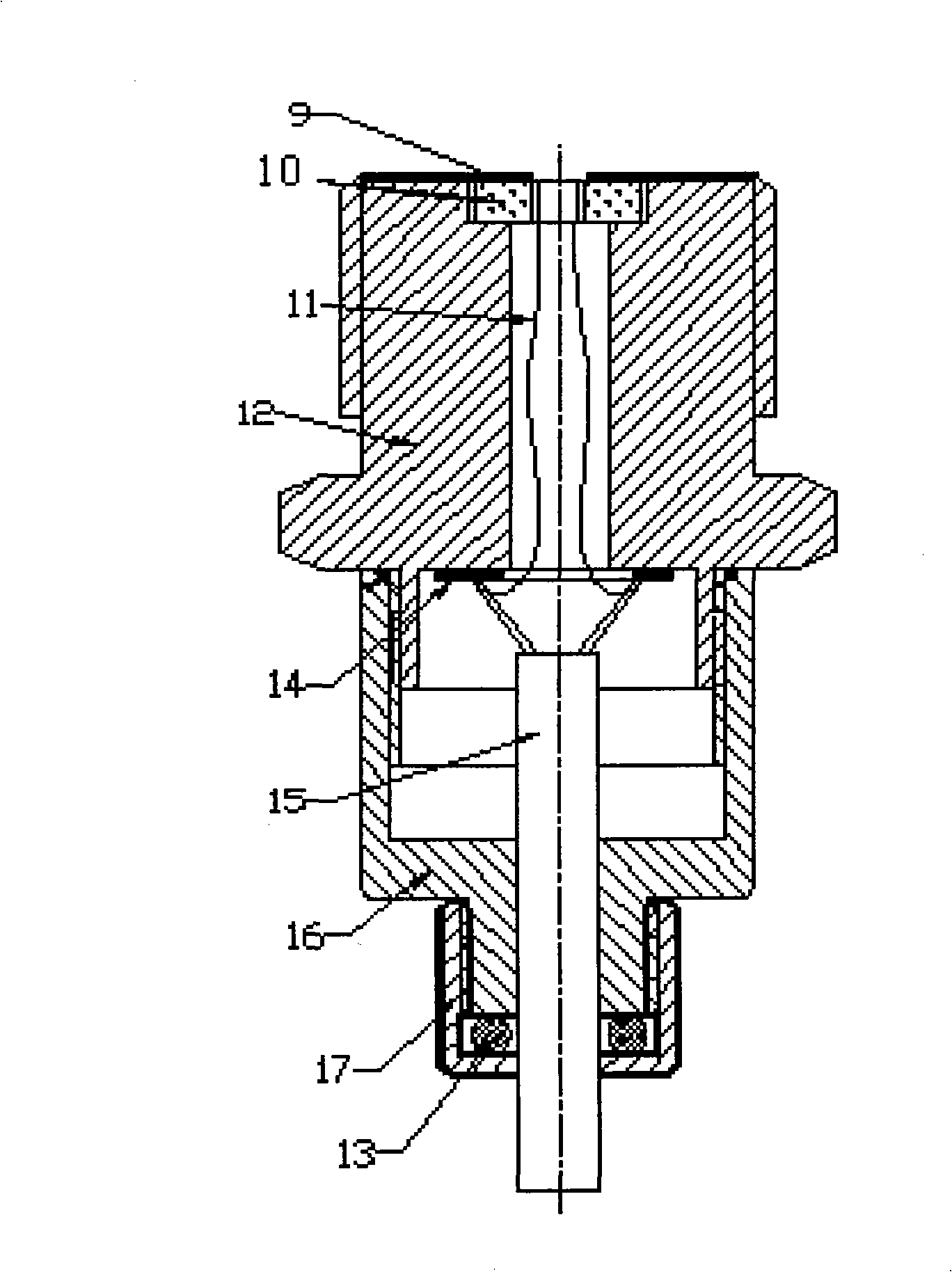

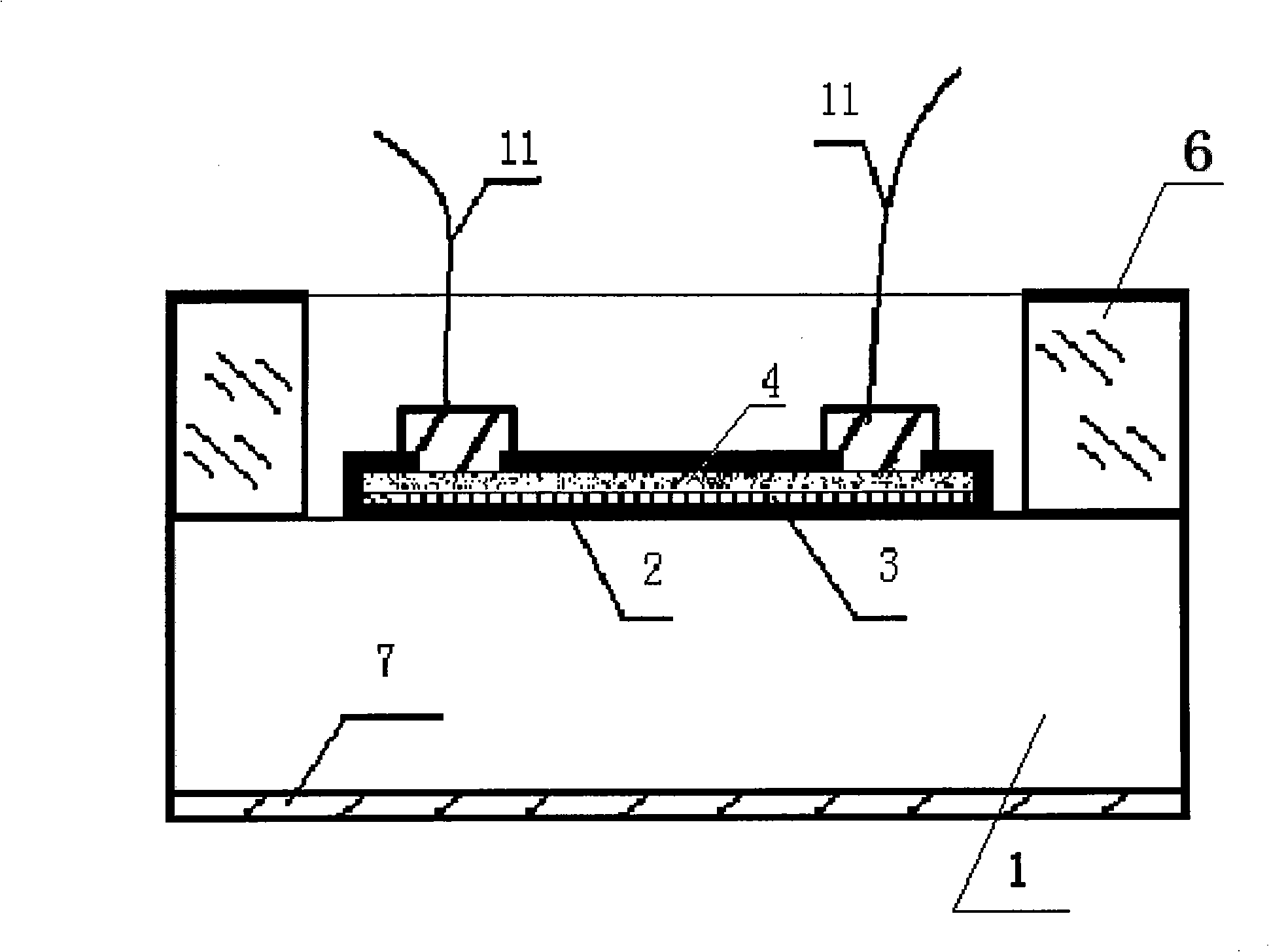

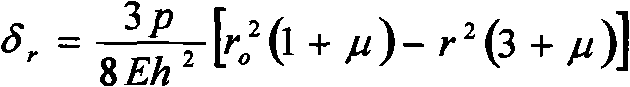

[0027] The following combination figure 1 , figure 2 For further description: a radiation-resistant pressure sensor, composed of a silicon piezoresistive sensitive component 10 and a metal housing, the silicon piezoresistive sensitive component 10 is composed of a silicon sensitive element with a Wheatstone bridge structure and a glass ring 6, The metal shell is composed of a metal base 12 and a metal cover 16 welded to the tail end of the metal base. The metal base 12 and the metal cover 16 form an inner chamber, and the front end of the metal base is provided as a pressure port. The back pressure surface ring part of the silicon sensitive element is fixed on the inner ring surface of the stepped hole through the glass ring 6, and the pressure surface of the silicon sensitive element is flush with the front surface of the metal shell and is conductively encapsulated The strain resistance 4 on the Wheatstone bridge structure is connected with a gold wire inner lead 11, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com