Pearlescent pigment

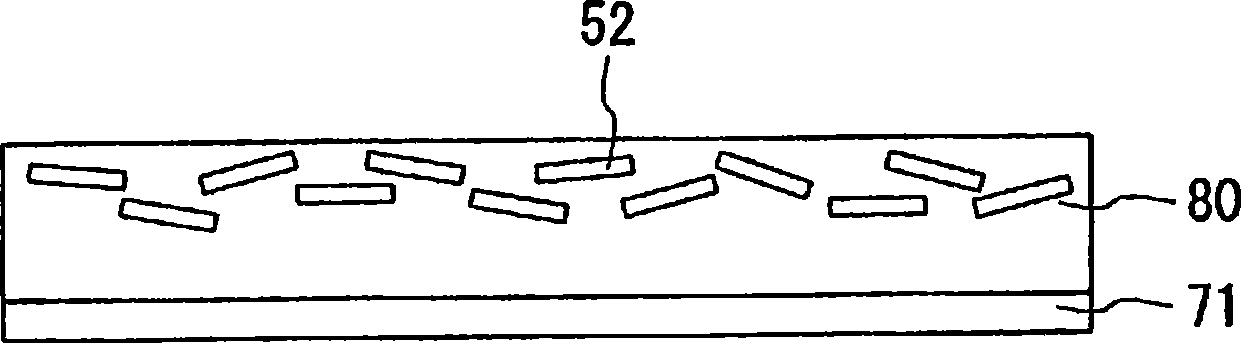

A technology for luster pigments and pearls, which is applied in inorganic pigment treatment, wet preparation of dyed pigments, fibrous fillers, etc., can solve the problems of disorganized orientation of pearl luster pigments and reduced flop, and improve the secondary water resistance. Adhesion and immersion suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

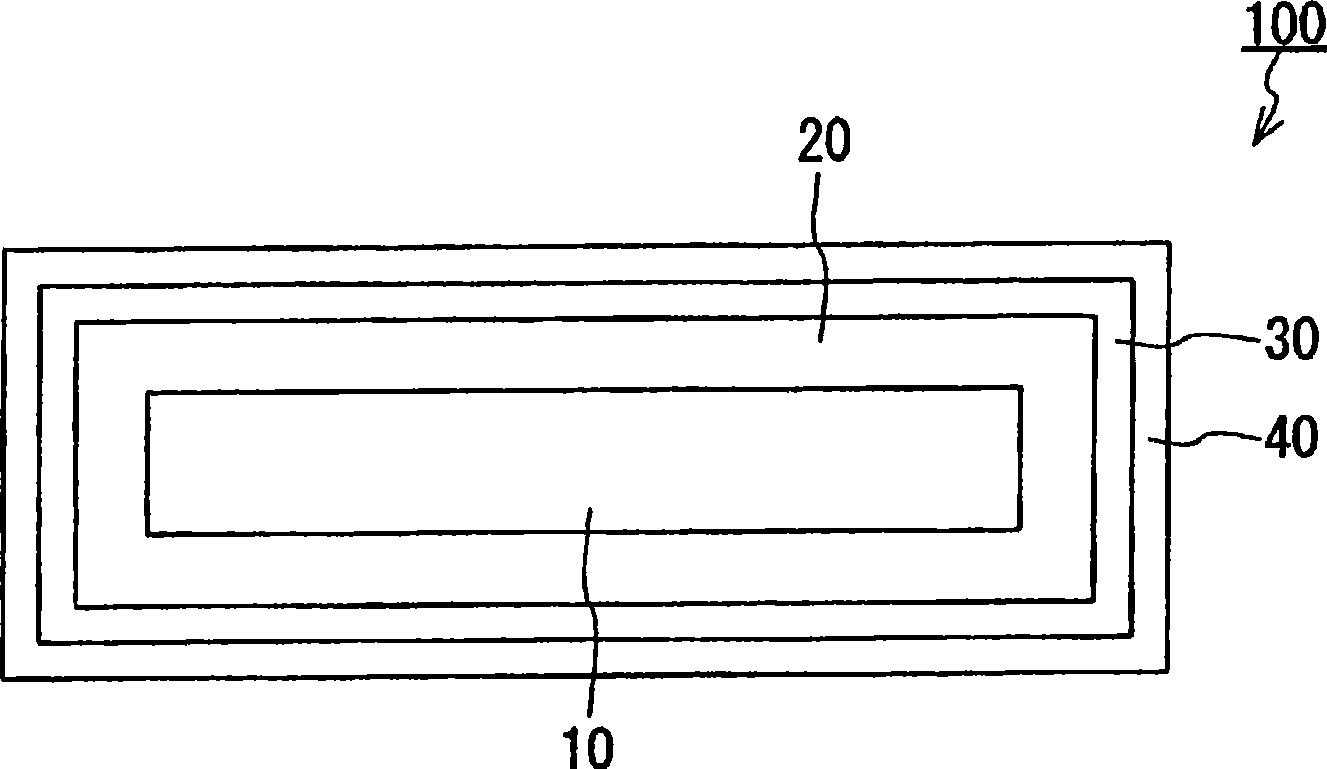

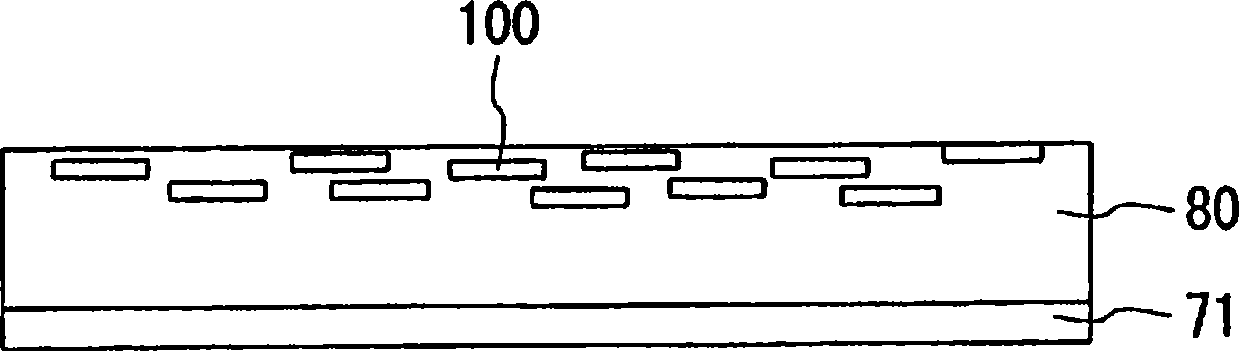

[0157] Example 1 is an example in which a coating of cerium hydroxide or oxide hydrate is formed on glass flakes coated with rutile-type titanium dioxide, and further, a coating of an oxazoline group-containing polymer is formed on the surface thereof.

[0158] Metashine (registered trademark) MC1020RB manufactured by Nippon Sheet Glass Co., Ltd. was used as a pearly luster pigment which is coated with rutile-type titanium dioxide and exhibits an interference color. The average particle diameter of this pearl luster pigment is 20 μm, the average thickness is 1.6 μm, the adhesion amount of rutile-type titanium dioxide is about 26% by mass, and exhibits blue luster interference color.

[0159] First, using cerium(III) nitrate hexahydrate [Ce(NO 3 ) 3 ·6H 2 O] 0.6g, prepare 2% by mass aqueous solution. About 50 g of the pearl luster pigment was suspended in 0.5 L (liter) of purified water, kept at 75° C. in a water bath, and adjusted to pH 6 with dilute nitric acid. Next, the...

Embodiment 2

[0163] Example 2 is a pearlescent pigment in which layers of flaky glass, rutile titanium dioxide, cerium hydroxide or oxide hydrate, an oxazoline group-containing polymer, and an organosilane coupling agent are sequentially formed.

[0164] As an organosilane coupling agent, 0.5 g of 3-methacryloxypropyltriethoxysilane (manufactured by Unika Co., Ltd. A-174) was prepared, poured into 0.5 L of ion-exchanged water, and stirred for hydrolysis. 2 g of an oxazoline group-containing polymer (EPOCROS WS-700 manufactured by Nippon Shokubai Co., Ltd., resin solid content 25% by mass, oxazoline value 220 g / eq) was prepared and added to the hydrolyzed solution of the silane coupling agent.

[0165] Add about 50 g of pearl luster pigment coated with cerium hydroxide or oxide hydrate to the hydrolyzate, stir for 30 minutes, then filter the suspension with filter paper, take out the filtered solid, and dry at 120°C for 2 hours . In this case, the added amount of the oxazoline group-contai...

Embodiment 3

[0168] Example 3 is a pearly luster pigment in which glass flakes, rutile-type titanium dioxide, a layer containing hydroxide or oxide hydrate of cerium and aluminum, and an oxazoline group-containing polymer were sequentially formed.

[0169] As the aluminum compound, 0.6 g of aluminum chloride hexahydrate was used, and a 2 mass % aqueous solution was prepared, and 0.6 g of cerium nitrate (III) hexahydrate was used, together with 2 mass % aqueous solution and 8.0 g of 1N sodium hydroxide aqueous solution. The same operation as in Example 1 was added to the suspension, washed with water, dried and filtered to obtain a pearly luster pigment coated with hydroxide or oxide hydrate of cerium and aluminum.

[0170] On the other hand, carry out in the same manner as in Example 1, prepare 2.0 g of an oxazoline group-containing polymer (EPOCROS WS-700 manufactured by Nippon Shokubai Co., Ltd., 25% by mass of resin solid content, 220 g / eq of oxazoline value), and drop into to 0.5 L of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com