Inorganic surface treating method for nano-zinc oxide

A nano-zinc oxide and surface treatment technology, applied in the field of nanomaterials, can solve problems such as poor inorganic surface treatment effect, and achieve the effects of easy control, short process flow, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

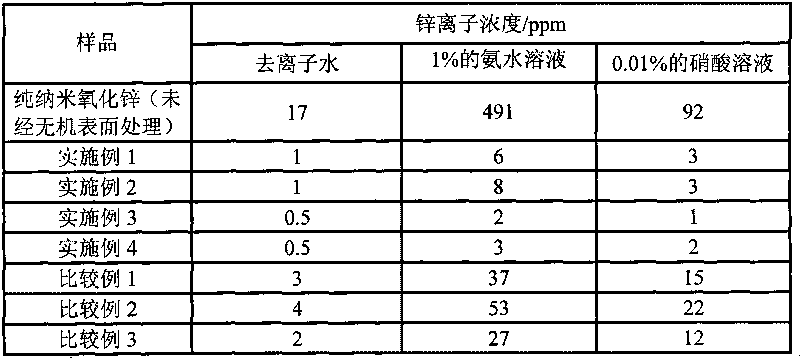

Embodiment 1

[0024] Specifically follow the steps below to implement:

[0025] (1) Get 1000g of nano-zinc oxide aqueous dispersion liquid that is 25% by mass percentage, adjust the temperature of nano-zinc oxide aqueous dispersion liquid to 30°C, while stirring, add mass percent 5% aluminum chloride (AlCl 3 ) aqueous solution and 3% sodium phosphate aqueous solution by mass percentage, and maintain the pH value of the system at 8.0, and the concurrent feeding time is 30 minutes. Amount of aluminum chloride to generate AlPO 4 The mass meter accounts for 3% of the nano zinc oxide mass. After adding the aqueous aluminum chloride solution, continue to stir and mature at 30° C. for 120 minutes.

[0026] (2) The temperature of the nano-zinc oxide slurry obtained in step (1) is raised to 95° C., while stirring, it is 30% sodium silicate aqueous solution added to the nano-zinc oxide slurry, the amount of sodium silicate to generate SiO 2 The mass meter accounts for 20% of the nano-zinc oxide ...

Embodiment 2

[0029] Specifically follow the steps below to implement:

[0030] (1) Get 1000g of nano-zinc oxide aqueous dispersion liquid that is 25% by mass percentage, adjust the temperature of nano-zinc oxide aqueous dispersion liquid to 90°C, while stirring, add mass percent 30% aluminum nitrate (Al(NO 3 ) 3 9H 2O) an aqueous solution and a 30% sodium phosphate aqueous solution by mass percentage, and maintain the pH value of the system at 10.0, and the concurrent feeding time is 300 minutes. Amount of aluminum chloride to generate AlPO 4 The mass meter accounts for 10% of the nano-zinc oxide mass. After adding the aqueous aluminum chloride solution, continue to stir and mature at 90° C. for 20 minutes.

[0031] (2) The temperature of the nano-zinc oxide slurry obtained in step (1) is lowered to 75° C., while stirring, it is 5% aqueous potassium silicate solution that is added by mass percentage to the nano-zinc oxide slurry, and the consumption of potassium silicate to generate ...

Embodiment 3

[0034] Specifically follow the steps below to implement:

[0035] (1) Get 1000g of nano-zinc oxide aqueous dispersion liquid with a mass percentage of 25%, adjust the temperature of nano-zinc oxide aqueous dispersion liquid to 50°C, while stirring, add mass percent 20% aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O) an aqueous solution and a 10% sodium phosphate aqueous solution by mass percentage, and maintain the pH value of the system at 9.0, and the concurrent feeding time is 150 minutes. Amount of aluminum chloride to generate AlPO 4 The mass meter accounts for 5% of the nano zinc oxide mass. After adding the aluminum sulfate aqueous solution, continue stirring and aging at 50° C. for 60 minutes.

[0036] (2) The temperature of the nano-zinc oxide slurry obtained in step (1) is raised to 85° C., and while stirring, it is 15% sodium silicate aqueous solution and sodium silicate to be added to the nano-zinc oxide aqueous dispersion. The dosage to generate SiO 2 The mass m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com