Method for processing and seasoning prawn products by fully utilizing prawns

A technology for seasoning shrimp and prawns, applied in the fields of food science and aquatic product processing, can solve the problems of violent processing intensity, single technology, loss of sensory quality of shrimp products, etc., achieves less energy consumption, overcomes poor flavor, and improves comprehensive utilization ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

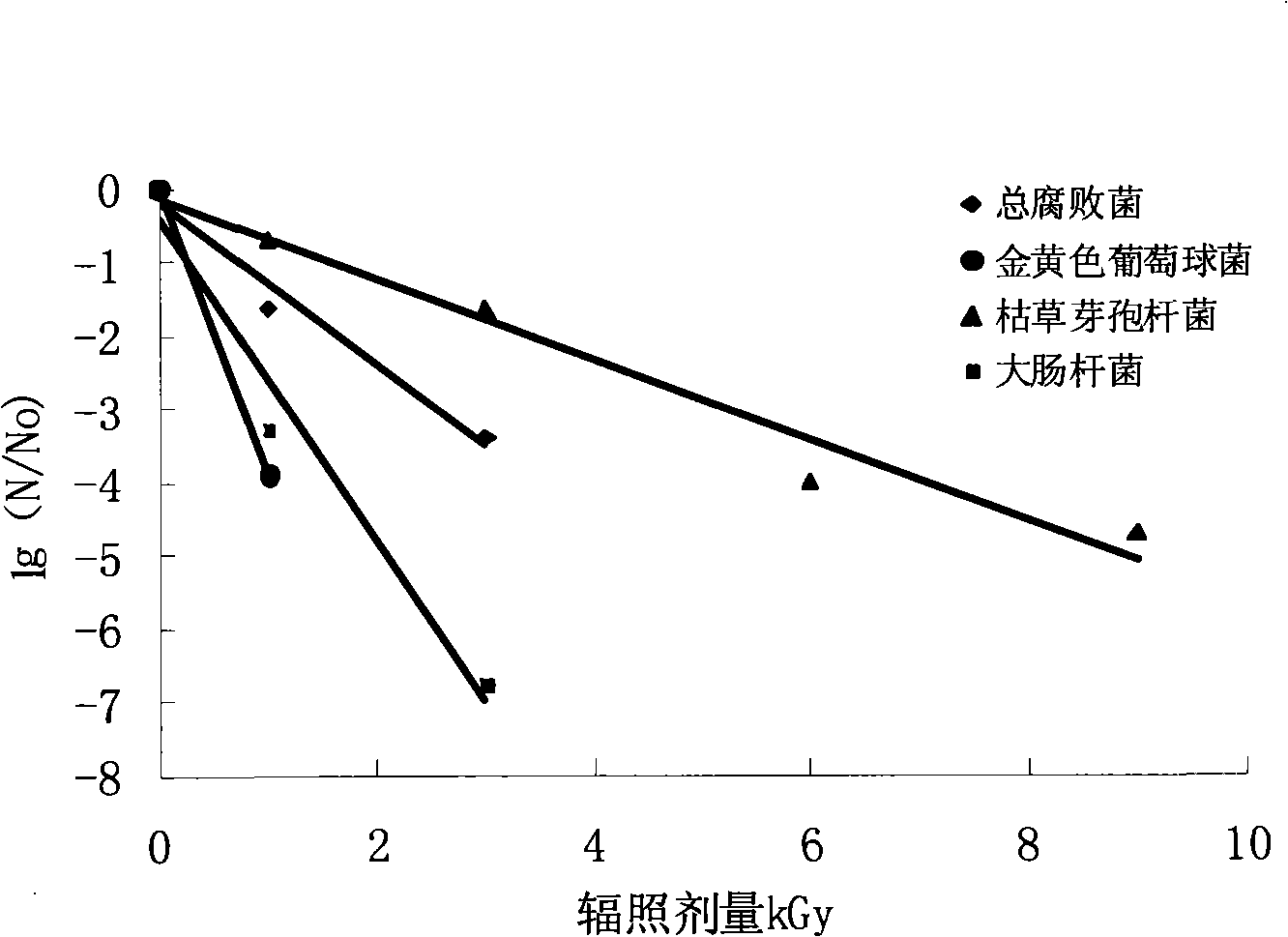

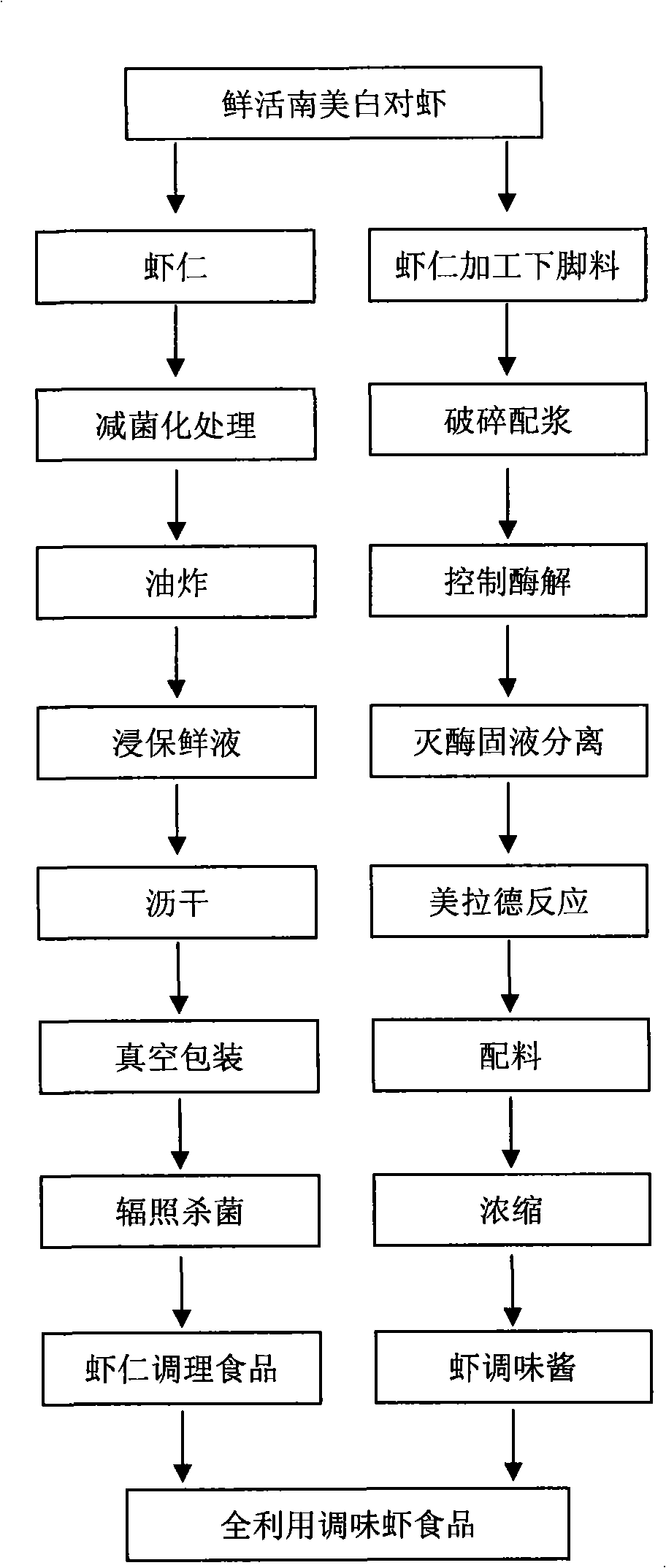

Embodiment 1

[0034] Fresh and live Penaeus vannamei remove the heads and shells, pick and remove the intestinal glands, wash, blanch in 3% boiling salt water for 120s, soak in 70% ethanol for 3min and then rinse, fry the shrimps in vegetable oil at 130°C for 80s, use Soak the shrimps in 1% potassium sorbate for 10 seconds, drain the fresh-keeping liquid, and pack them in vacuum at a vacuum degree of 90kPa. After packaging, they will be irradiated with a dose of 6kGy. After the irradiation, the prepared shrimp food will be obtained; Squeeze the tissue and break it, add drinking water according to the mass ratio of shrimp scraps / water 1:2, use 0.2M phosphate buffer to adjust the pH value to 7.0, add Flavourzyme (flavor protease) in an amount of 0.5g enzyme / 100g protein, and stir for 6 hours at 50°C , the degree of hydrolysis at the end of the reaction was 37.22%, and the solid content was 6.12%. The above-mentioned enzymolysis solution was inactivated in a water bath at 86°C for 15 minutes, ...

Embodiment 2

[0036] Fresh and live Penaeus vannamei remove the heads and shells, remove the intestinal glands, wash, blanch in 3% boiling salt water for 70 seconds, soak in 70% ethanol for 3 minutes and then rinse, and fry the shrimps in vegetable oil at 135°C for 80 seconds. Sodium lactate (0.2%), nisin (0.2%) and lysozyme (0.6%) compound fresh-keeping solution soaked shrimps for 10s, drained the fresh-keeping solution and then vacuum-packed at a vacuum degree of 100kPa. The dose is 9kGy, after the irradiation is finished, the shrimp preparation food is obtained; the fresh shrimp processing scraps are squeezed and the tissues are crushed, and the drinking water is added according to the shrimp scraps / water mass ratio of 1:1.5, and the pH value is adjusted to 7.3 with 0.2M phosphate buffer solution. Add 0.5g Alcalase and 0.5g Flavorzyme to every 100g protein, stir at 50°C for 4h, the degree of hydrolysis is 42.31% after the reaction, and the solid content is 6.39%. The above-mentioned enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com