Method for analyzing components of iron ore by using X-ray fluorescence spectrum

A fluorescence spectroscopy, iron ore technology, applied in the field of X-ray fluorescence spectroscopy analysis of iron ore components, can solve the problems of time-consuming, troublesome, error-prone, etc., and achieves simplified measurement procedures and time, high measurement accuracy, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

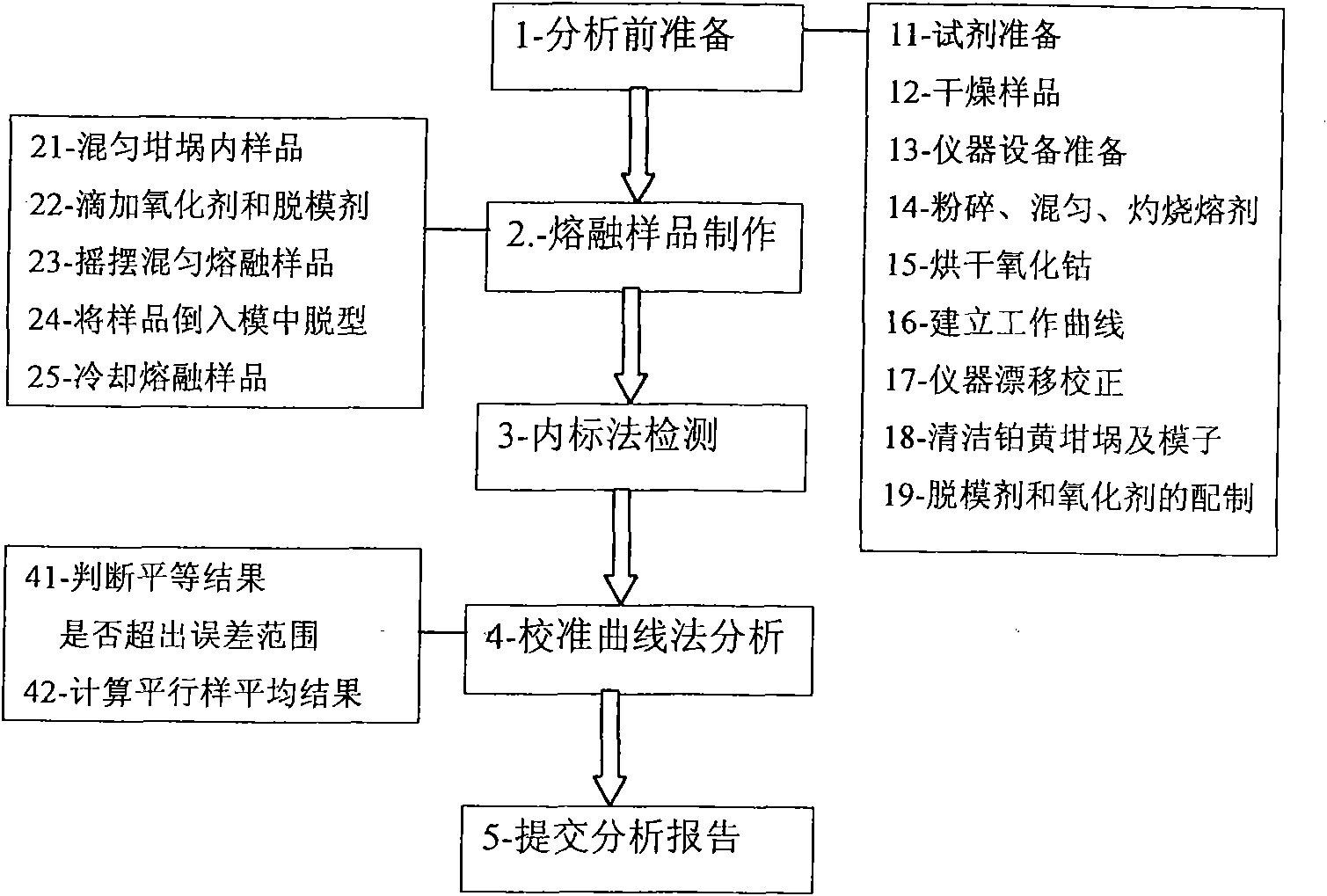

Method used

Image

Examples

Embodiment

[0030] Reagents and materials: P10 gas, a mixed gas composed of 90% argon and 10% methane, is used for a flow proportional counter.

[0031] Flux: high-grade pure lithium tetraborate or lithium tetraborate and lithium metaborate 67+33 mixed flux, bake at 500°C for 4 hours, cool in a desiccator for later use.

[0032] Dicobalt trioxide, superior grade, baked at 105°C for 1 hour, and cooled in a desiccator for later use.

[0033] [LiNO 3 =400g / L or NaNO 3 =400g / L and LiBr=400g / L or NH 4 I=400g / L] Mixed solution: Weigh 400.0g of analytically pure lithium nitrate or sodium nitrate and 400.0g of analytically pure lithium bromide or ammonium iodide and dissolve in water and dilute to 1000mL.

[0034] HNO 3 : 1+5 volume ratio.

[0035] X-ray fluorescence spectrometer: Simultaneous or sequential wavelength dispersive spectrometer, which meets the requirements of "JJG810 Wavelength dispersive X-ray fluorescence spectrometer in the National Metrology Verification Regulations of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com