Method for preparing easily dissolved zinc glycine

A technology for dissolving zinc glycinate and zinc glycinate, which is applied in the field of preparation of easily soluble zinc glycinate, can solve the problems of only 30% or less, difficult absorption of zinc nutrition, and low synthesis rate of finished products, so as to achieve stable blood zinc level and no adverse effects Response, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

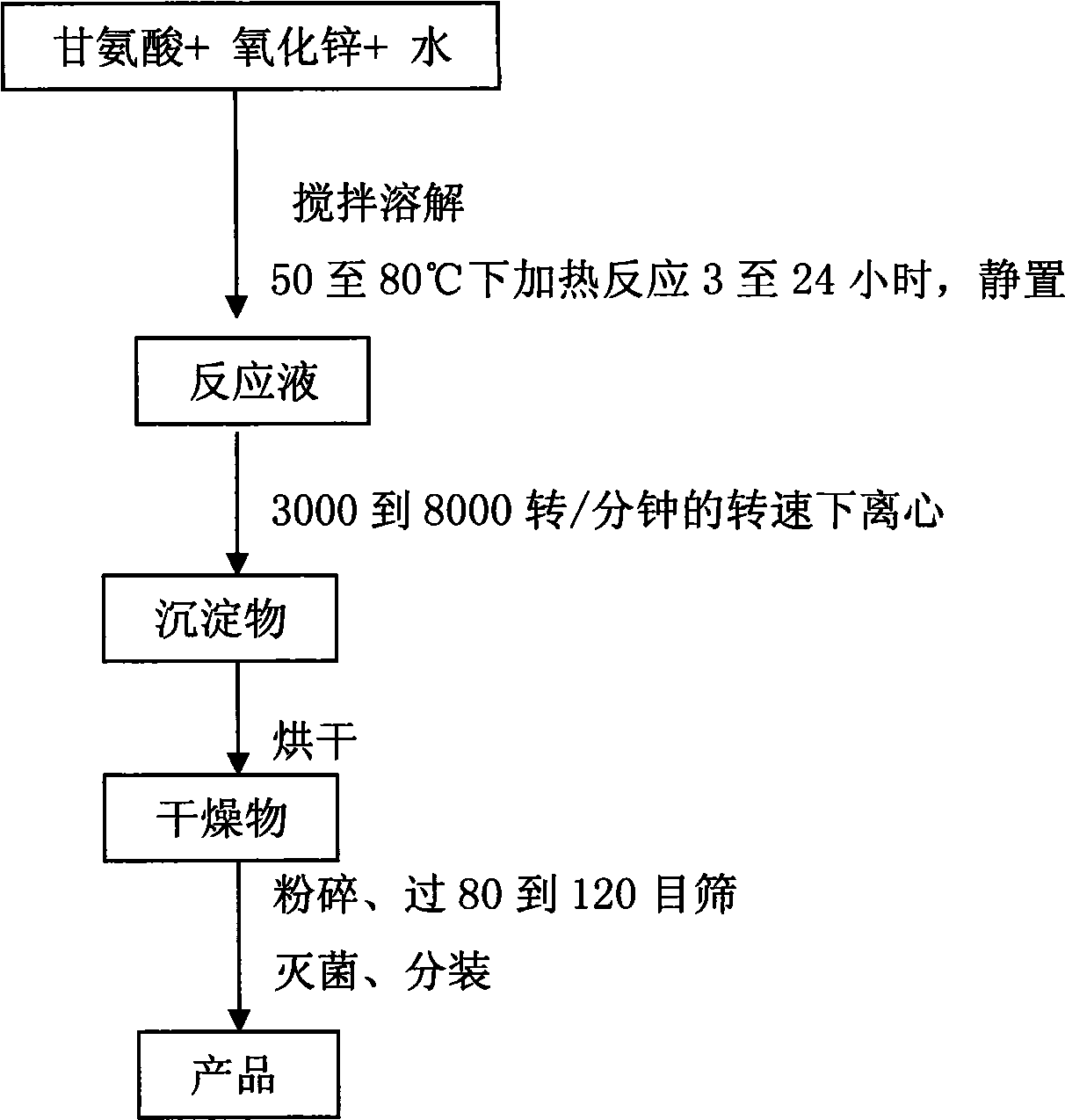

Method used

Image

Examples

Embodiment 1

[0021] Take 50kg of raw material glycine, 50kg of nano-sized zinc oxide and 760kg of water, mix them in a reactor, stir to fully dissolve, react at a temperature of 50°C for 6 hours, take the reaction solution, and let it stand for 8 hours; at a speed of 3000 rpm Centrifuge for 1 hour, take the precipitate obtained by centrifugation, place it in an oven and dry it at 80°C, check the moisture content, make the moisture content less than 9%, and obtain 89kg of dry matter, take the dried matter, crush it, and pass through a 100-mesh sieve. Sterilize and aliquot.

Embodiment 2

[0023] Take 150kg of raw material glycine, 100kg of nano-sized zinc oxide and 800kg of water, mix them in a reactor, stir to fully dissolve, react at 80°C for 12 hours, take the reaction solution, and let it stand for 6 hours; at a speed of 5000 rpm Centrifuge for 2 hours, take the precipitate obtained by centrifugation, put it in an oven and dry it at 120°C, check the moisture content, make the moisture weight percentage less than 9%, and obtain 238 kg of dry matter, take the dried matter, crush it, and pass through an 80-mesh sieve. Sterilize and aliquot.

Embodiment 3

[0025] Take 70kg of raw material glycine, 30kg of nano-sized zinc oxide and 900kg of water, mix them in a reactor, stir to fully dissolve, react at a temperature of 70°C for 18 hours, take the reaction solution, and let it stand for 6 hours; Centrifuge for 1 hour, take the precipitate obtained by centrifugation, place it in an oven and dry it at 100°C, check the moisture content, make the moisture weight percentage less than 9%, and obtain 93kg of dry matter, take the dried matter, crush it, and pass through a 120-mesh sieve. Sterilize and aliquot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com