Method for clearing and detecting vanadic oxide

A vanadium pentoxide and detection method technology, which is applied in the detection field of plasma mass spectrometry, can solve problems such as component corrosion, influence on measurement results, pollution, etc., and achieve the effects of avoiding volatilization loss and pollution, high precision, and simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

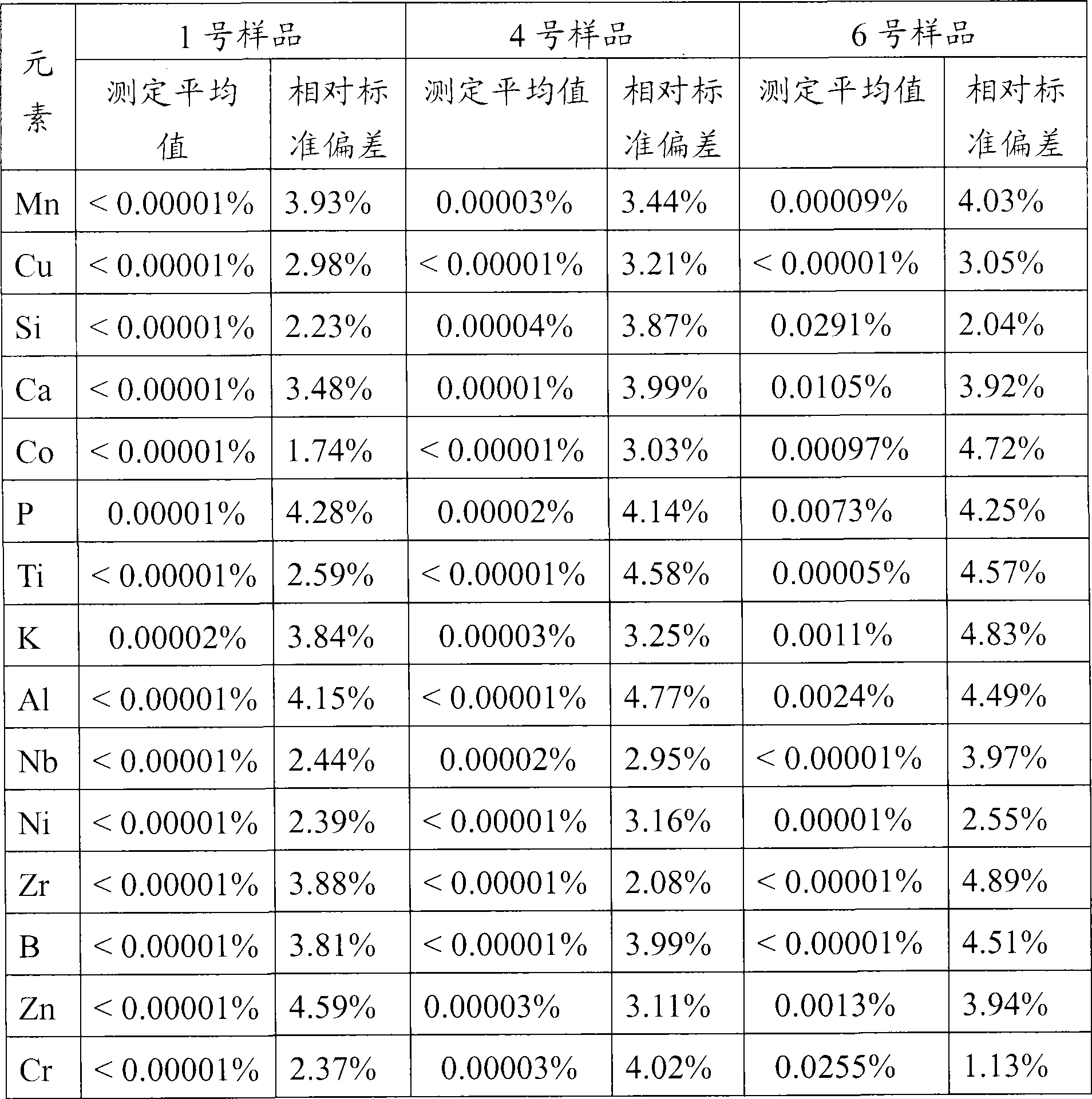

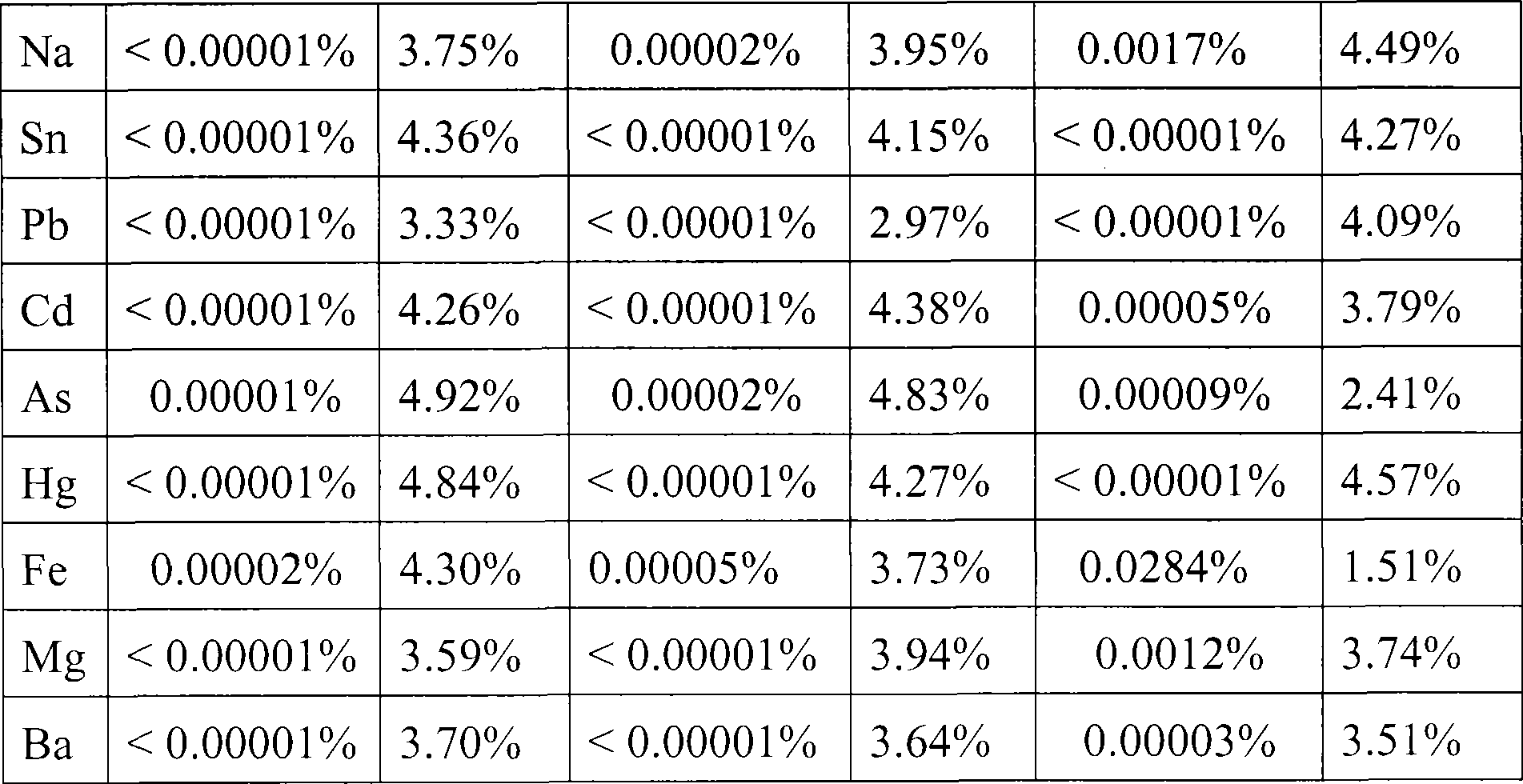

Examples

Embodiment 1

[0036] The nitric acid, hydrofluoric acid and water used in this example are of ultra-pure grade, the microwave digestion system used is Mars5 produced by CEM Company of the United States, and the ICP-MS is an inductively coupled plasma mass spectrometer of Elan9000 of PE Company of the United States.

[0037] V 2 O 5 Sample digestion

[0038] Weigh 0.1000g of high-purity V with grade ≥99.999% 2 o 5 The sample (incoming product packaging) (hereinafter referred to as sample No. 1) is placed in the microwave digestion inner tank, and 3.0 mL of nitric acid with a concentration of 65% to 68% by mass is added dropwise along the tank wall, and placed at room temperature for 3 minutes , then add 0.2mL of hydrofluoric acid with a mass percentage concentration of 40% to 47%, 2.0mL of 500ng / mL Rh standard solution, and 2.0mL of 500ng / mL Sc standard solution into the inner tank, and wash the tank wall with about 4.0mL of water Then put the outer tank on, cover the lid and tigh...

Embodiment 2

[0051] V to be digested 2 o 5 The sample is 0.1000g grade ≥ 99.99% high-purity V 2 o 5 Sample (Shanghai Reagent No. 1 Factory) (hereinafter referred to as sample No. 2), using 3.0mL nitric acid, 0.5mL hydrofluoric acid, 2.5mL of 500ng / mL Rh standard solution and 2.5mL of 500ng / mL Sc standard solution, in addition Outside, digest V according to the same method as the method of Example 1 2 o 5 samples and tested.

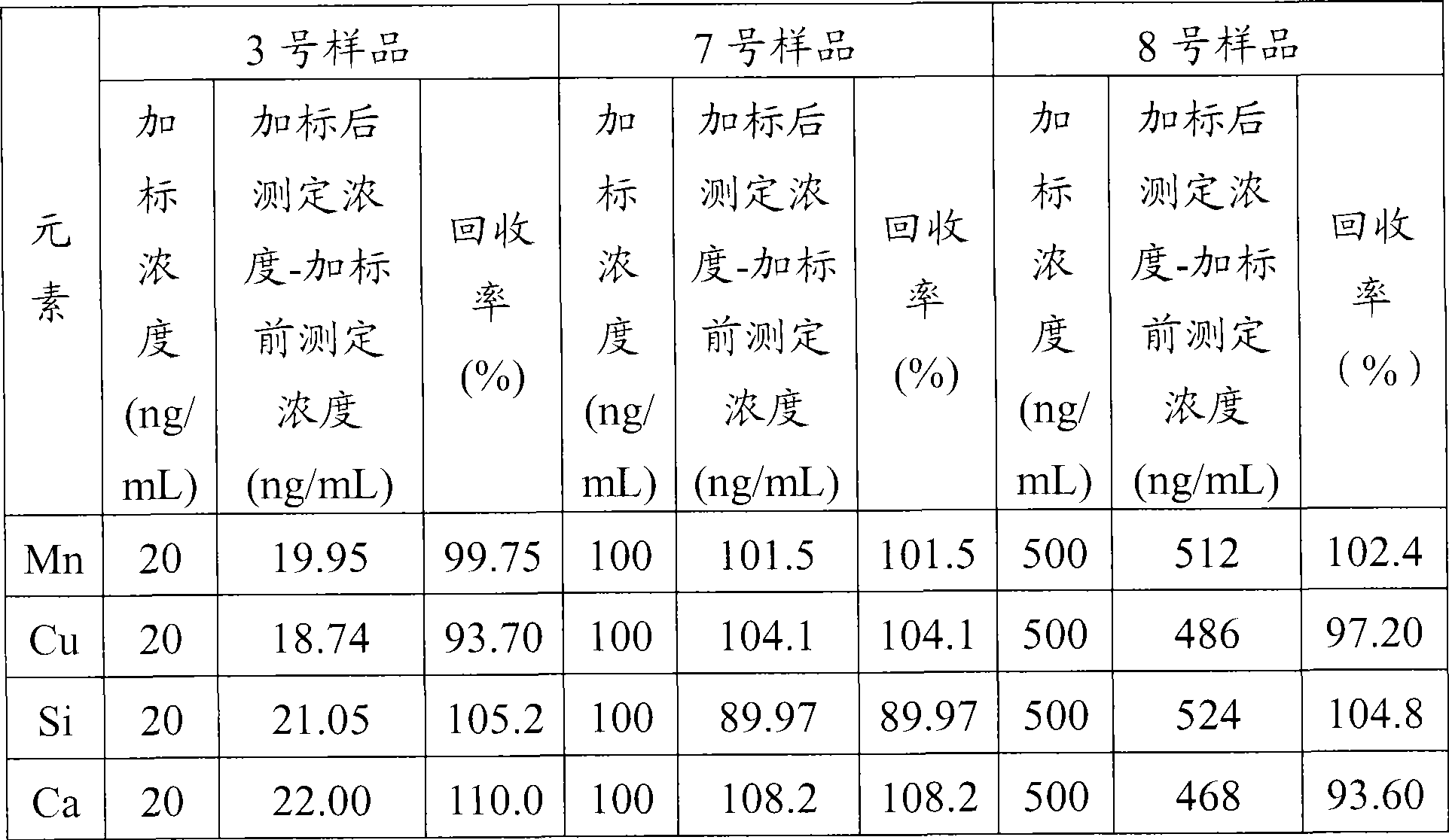

Embodiment 3

[0053] V to be digested 2 o 5 The sample is 0.1000g grade ≥ 99.999% high-purity V 2 o 5 Sample (repacking of imported products) (hereinafter referred to as sample No. 3), using 3.0mL nitric acid, 0.3mL hydrofluoric acid, 2.0mL of 500ng / mL Rh standard solution and 2.0mL of 500ng / mL Sc standard solution, in addition Outside, digest V according to the same method as the method of Example 1 2 o 5 samples and tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com