Heat treating method for pulse laser settled hydroxylapatite-bioglass composite film

A pulsed laser deposition, hydroxyapatite technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve problems affecting application, affecting film performance, etc., to achieve the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

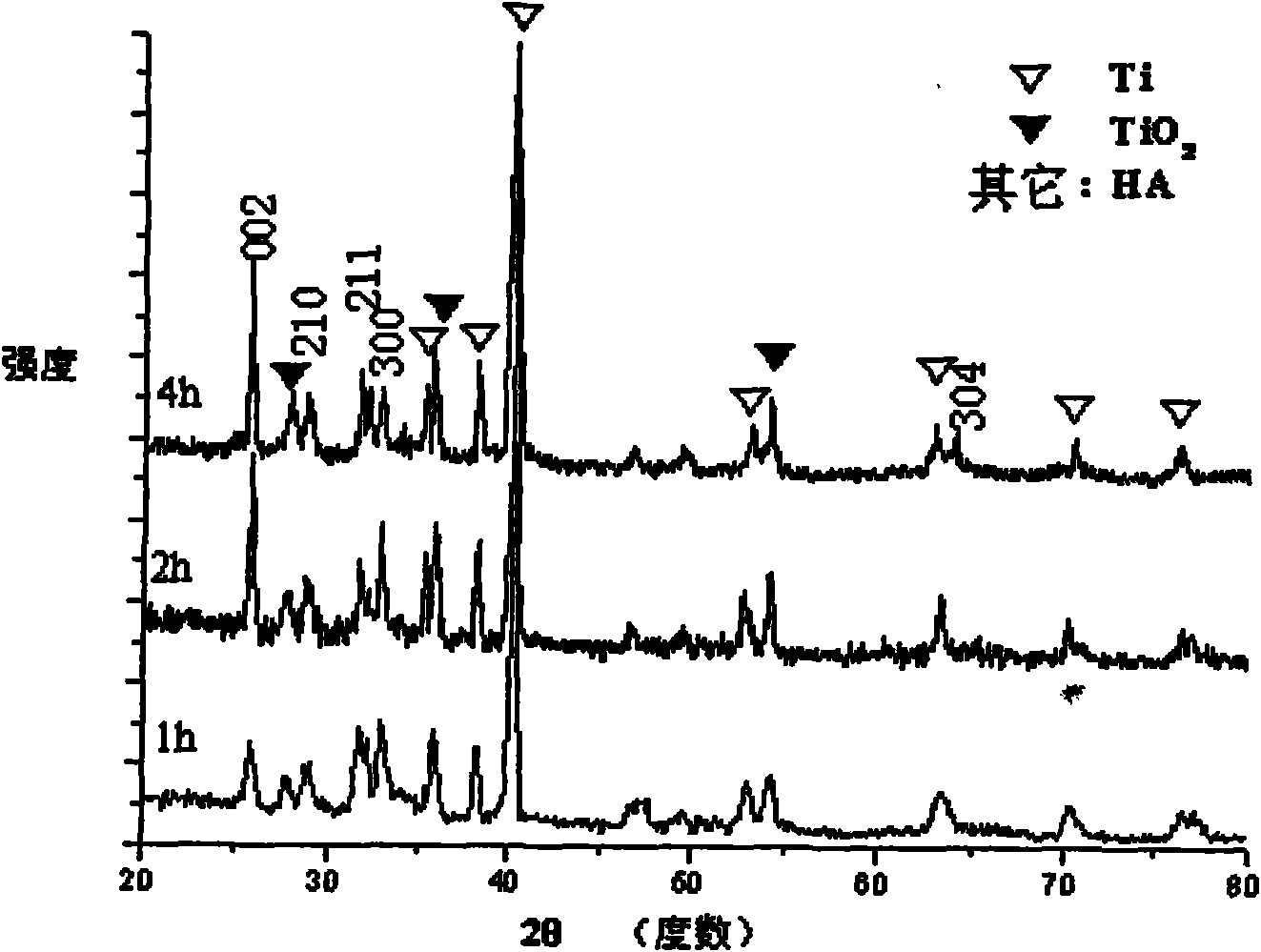

[0014] Preparation of pulsed laser deposited hydroxyapatite-bioglass composite film: mix highly crystalline HA and amorphous 45S5 bioglass powder at a weight ratio of 1:1, and then ball mill it under a pressure of 240MPa, cold isostatic pressing method Press into a Φ25mm×3mm sheet target, and heat treat the target at 600°C for 2 hours after pressing; fix the target and matrix material in the reaction chamber for ablation and deposition, and adjust the distance between the matrix and the target to 5.5cm , using a molecular pump to evacuate the deposition chamber to 5×10 -5 Pa, through the adjustment of the vacuum needle valve, argon gas is introduced, the pressure is 45Pa, the substrate is heated by the resistance wire, the heating rate is 40°C / min, and the temperature is 200°C, the target is 360r / h, the substrate is 40r / h Speed rotation; start the laser, laser ablation target, choose KrF laser (wavelength 248nm), laser frequency 5-10Hz, pulse number 18000, laser output energ...

Embodiment 2

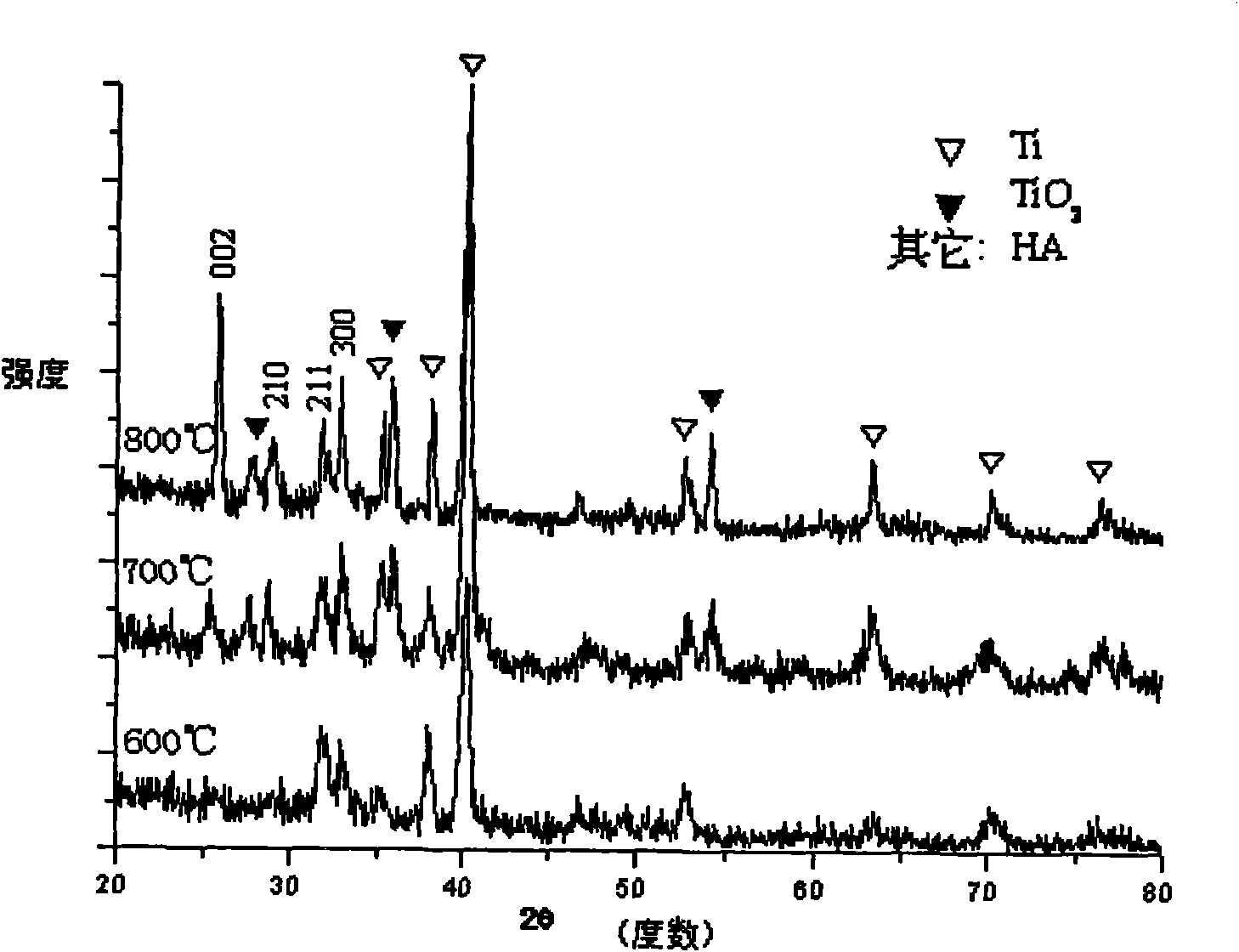

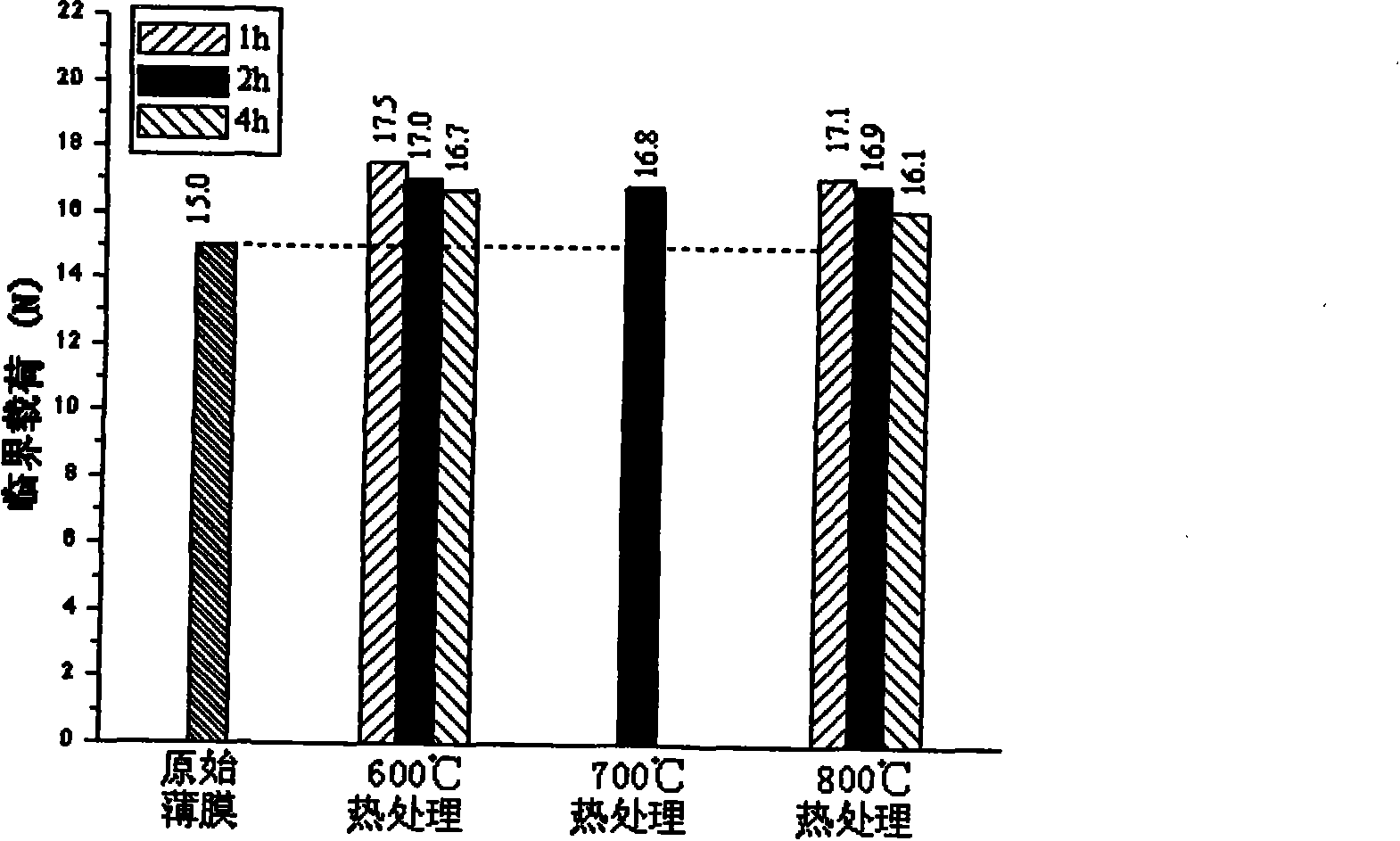

[0016] The pulsed laser-deposited hydroxyapatite-biological glass composite film obtained in Example 1 was heat-treated at 600°C in an ordinary box-type resistance furnace, kept for 1 hour, and the heating rate was 5°C / min, and then cooled with the furnace.

Embodiment 3

[0018] The pulsed laser-deposited hydroxyapatite-biological glass composite film obtained in Example 1 was heat-treated in a common box-type resistance furnace at 600°C, kept for 2 hours at a heating rate of 5°C / min, and then cooled with the furnace.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap