Bioactive phosphorus nutritional agent

A technology of active phosphorus and nutrients, applied in the environmental field, can solve the problems of affecting sludge settleability, excessive phosphorus content, and increasing the amount of remaining sludge, so as to reduce the scaling and corrosion of pipelines, avoid new pollution, and increase the amount of sludge used Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

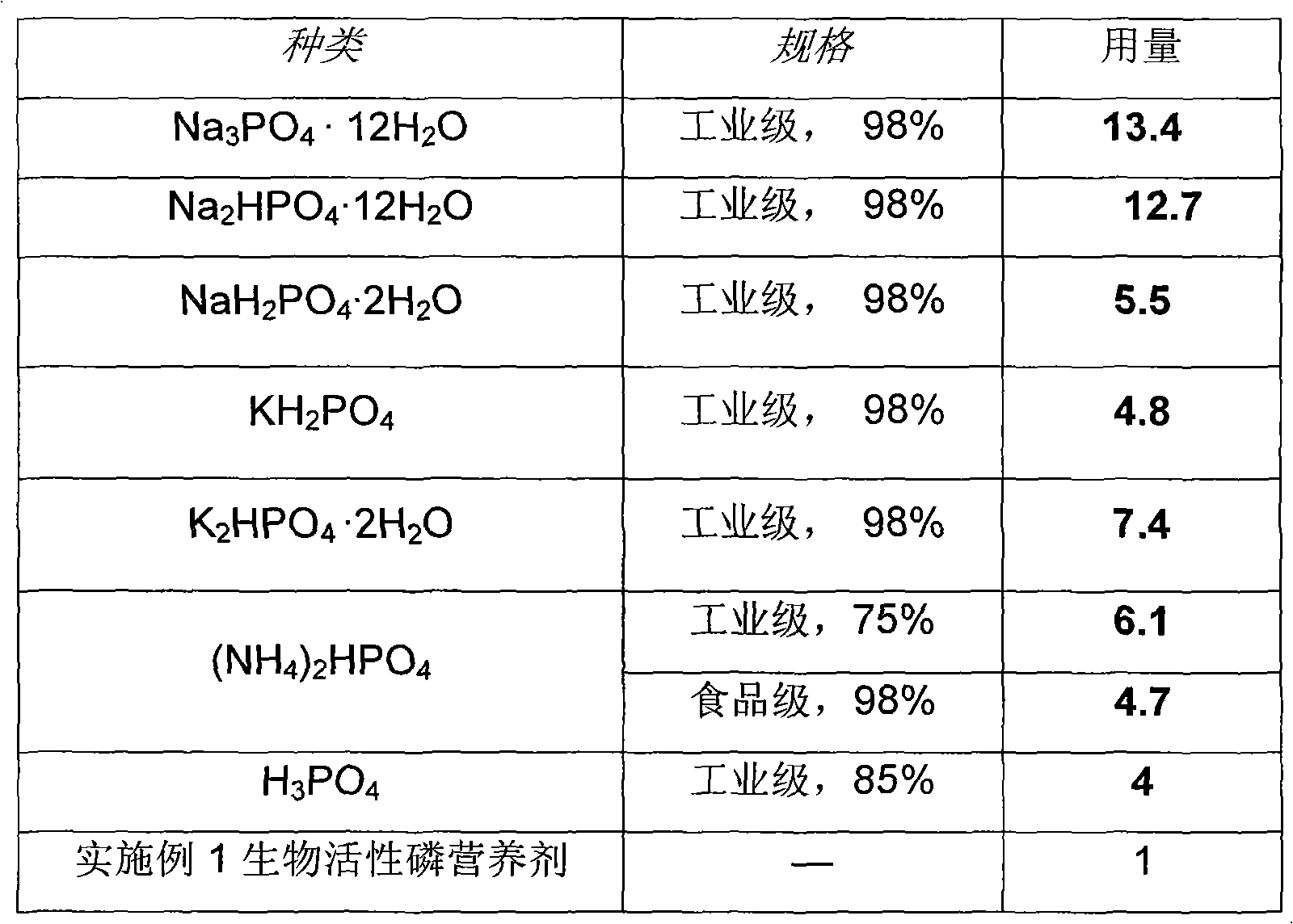

[0026] Mix the following raw materials, add water to a total weight of 100kg, and stir in a mixing tank for 8 hours before filtering, and the obtained liquid is a biologically active phosphorus nutrient:

[0027] 1) 85% industrial grade phosphoric acid 73kg (according to P 2 o 5 45kg in total)

[0028] 2) Salts of trace elements, specifically: Co(NO 3 ) 2 ·6H 2 O 99g (cobalt 20g), ZnCO 3 288g (zinc 150g), Na 2 MoO 4 2H 2 O 25g (molybdenum 10g), CuCl 2 2H 2 O 671g (copper 250g), MgCO 3 ·3H 2 O 2.13kg (magnesium 370g), Mn (NO 3 ) 2 4H 2 O 274g (manganese 60g), Fe (NO 3 ) 3 9H 2 O1.01kg (iron 140g), a total of 4.5kg, calculated as 1kg by weight of trace elements;

[0029] 3) Organic acid 10kg, including 0.5kg each of alanine, glutamic acid, aspartic acid and phenylalanine (2kg amino acids in total), 0.5g each of deoxyribonucleic acid and ribonucleic acid (1kg nucleic acid in total), 1kg Acetic acid and 2kg nitrohumic acid;

[0030] 4) 5kg of carbohydrates, in...

Embodiment 2

[0036] Mix the following raw materials, add water to a total weight of 100kg, and stir in a mixing tank for 8 hours before filtering, and the obtained liquid is a biologically active phosphorus nutrient:

[0037] 1) 98% industrial grade KH 2 PO 4 9.8kg (press P 2 o 5 Calculated as 5kg), 85% industrial grade phosphoric acid 49kg (according to P 2 o 5 Calculated as 30kg)

[0038] 2) Soluble salts of trace elements, specifically: Co(NO 3 ) 2 ·6H 2 O 494g (cobalt 100g), ZnCO 3 674g (zinc 350g), Na 2 MoO 4 2H 2 O 378g (molybdenum 150g), CuCO 3 ·Cu(OH) 2 696g (copper 400g), MgCO 3 2.88kg (magnesium 500g), Mn(NO 3 ) 2 4H 2 O 913g (manganese 200g), Fe(NO 3 ) 3 9H 2 O 2.16kg (iron 300g), a total of 8.19kg, calculated as 2kg by weight of trace elements;

[0039] 3) 5kg of organic acids, including 1.25kg each of alanine, glutamic acid, aspartic acid and phenylalanine (5kg amino acids in total), 1g each of deoxyribonucleic acid and ribonucleic acid (2kg nucleic acid i...

Embodiment 3

[0046] The biologically active phosphorus nutrient obtained in Example 2 is used in the sewage treatment plant of the petrochemical plant, and after dilution and mixing are uniformly made using the original disodium hydrogen phosphate device, it is added into the pH adjustment tank with a metering pump, and The pretreated water is fully mixed, and then enters the biochemical treatment section to provide nutrients such as phosphorus required for the growth of activated sludge.

[0047] The effect is as follows:

[0048] (1) The average COD removal rate of the biochemical system reaches 90.12%, and the highest value reaches 94.3%, which is about 8 percentage points higher than before use on average.

[0049] (2) The sludge concentration in the aeration tank decreased significantly, the average value decreased from 31181mg / l before use to 28568mg / l, an average decrease of 8.3%, which effectively reduced the total amount of sludge in the system.

[0050] (3) The content of organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com