Biomass pretreatment method, method and equipment for preparing firedamp by biomass anaerobic fermentation

An anaerobic fermentation and pretreatment technology, which is applied to fertilizers made from biological waste, bio-organic part treatment, fermentation, etc., can solve the problems of adverse effects of residue utilization, low volumetric efficiency of reactors, and slow growth of bacteria. Achieve the effects of improving biodegradability, accelerating fermentation speed and avoiding emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

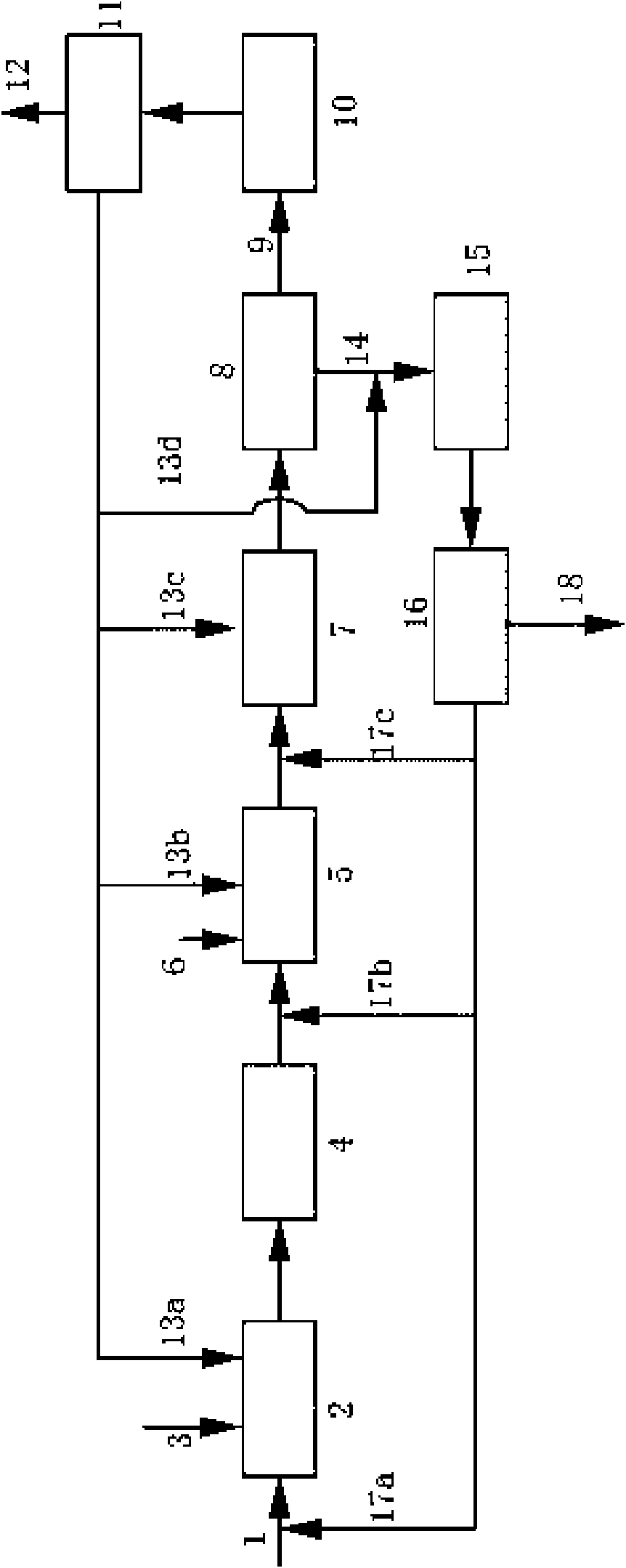

[0027] like figure 1 As shown, the biomass 1 (corn stalks in this example) is crushed to 20 mm by a crusher (not shown in the figure), and sent to the infiltration tank 2, and water 3 is added according to the proportion of 25% of the weight content of the straw. Soak for 1 hour. Then it is sent to the shredder 4, and under the action of two round rollers with different linear speeds, the soaked straw is torn into thin slices, and then sent to the ultrasonic infiltrator 5, and nitric acid is added in a proportion of 0.65% of the total weight. (6 in the figure), the ultrasonic wave acts for 2.5 minutes. Afterwards, it is sent to the hydrothermal reactor 7, and the hydrothermal reaction is carried out for 1 hour under the condition of 138° C., and the straw is decomposed into biodegradable substances. The material after the hydrothermal reaction is sent to a press machine 8 to be separated into a saccharified liquid 9 and a saccharified straw residue 14 . The saccharification...

Embodiment 2

[0029] Processing systems such as figure 1 As shown, the difference is that the mixture of wheat straw (chopped to 40mm) and wood sawdust (by weight, wheat straw: wood sawdust is 2:1) is sent into the soaking tank, and in the soaking tank, it is pressed Add nitric acid at a ratio of 0.2% of the total weight and phosphoric acid at a ratio of 0.05% of the total weight, soak for 15 minutes at 80°C, then act for 45 seconds under ultrasonic energy density of 1.0W / cm2, and then perform hydrothermal treatment at 180°C React for 10 minutes. The press for the pretreated material is a belt filter press. After fermentation, the saccharification residue is directly used as fertilizer without pressing. The biomass conversion rate was 52%. Compared with no hydrothermal reaction, the fermentation speed is increased by more than 2 times, and the volume load of liquid phase fermentation is increased by more than 2 times.

Embodiment 3

[0031] The rice straw broken to 10mm and the cassava stalk of 3mm (by weight, rice straw: cassava stalk is 2:1) are sent into such as figure 1 Immersion tank of the system shown, carrying out hydrothermal reaction and methane fermentation. The difference is that nitric acid is added in a proportion of 0.2% of the total weight, sulfuric acid is added in a proportion of 0.05%, hydrochloric acid is added in a proportion of 0.01%, phosphoric acid is added in a proportion of 0.02%, soaked at 60°C for 2 hours, and shredded Finally, under the condition that the ultrasonic energy density is 3W / cm2, it acts for 20 seconds. The hydrothermal reaction temperature is 130° C., and the time is 2 hours. Pressing with a screw press. The saccharification residue is directly used as fertilizer without fermentation. The liquid phase reactor can reach more than 18kg-COD / (m3·d), and the biomass conversion rate can reach 66%. Compared with the mixed fermentation, the liquid phase fermentation vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com