Semi-vertical reverberatory furnace for preparing sodium sulfide and process thereof

The technology of sodium sulfide and reverberatory furnace is applied to the semi-vertical reverberatory furnace and process field, which can solve the problems of high labor intensity, low thermal efficiency, difficult maintenance and other problems, and achieve the effects of reduced labor intensity, high thermal efficiency, and reduced workshop pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

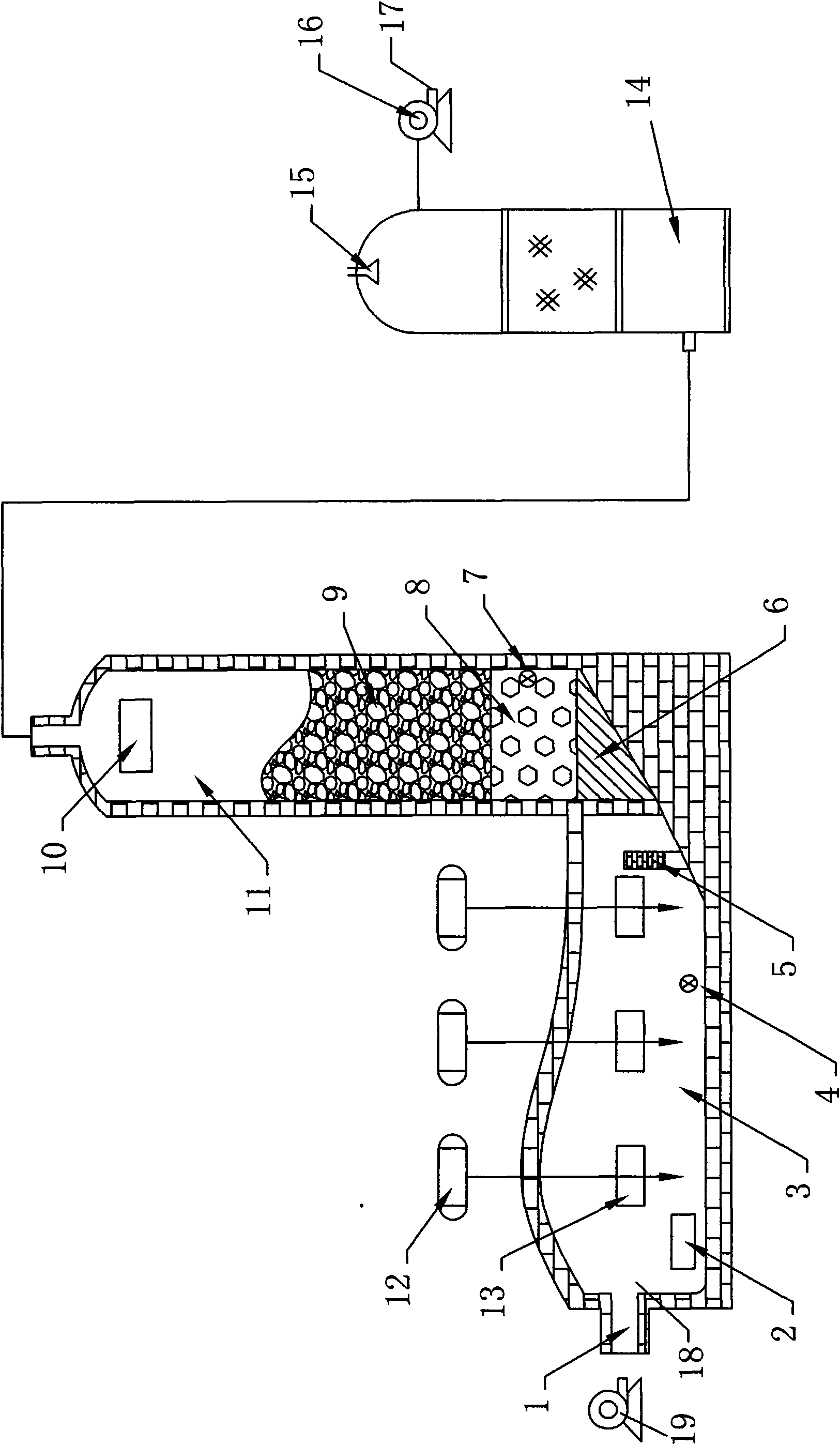

[0034] When the semi-vertical reverberatory furnace for preparing sodium sulfide of the present invention is specifically used, the raw material ball is put into the feeding port 10 at the top of the vertical furnace 11, and coal powder is sprayed into the combustion chamber 18 to make it fully combustible, and the high-temperature gas passes through the negative pressure device. The front bed part 3 and the vertical furnace 11 melt the raw material mass, and the reactants in the molten state flow back into the front bed part 3 after passing through the high temperature resistant filler layer 7, and the secondary coal is added through the secondary coal feeding port 13 to form a molten material. The front bed part 3 uses high-pressure gas to vigorously stir the molten material until the reaction is completed, and the molten material is continuously released from the discharge port 2. In the gas scrubber 14, the molten material is passed through the dilute lye for secondary washi...

Embodiment 1

[0039] Raw material group: Yuanming powder: white coal: water with a weight ratio of 100:25:6, pressed into a raw material group by a pair of rollers, such as pressed into a pellet, and placed for 12 hours. The section of the vertical furnace 11 is 2.5 square meters, the effective height is 4.5 meters, the triangular refractory brick furnace bar is matched with the furnace bottom, and 4 layers of 80mm Pall ring layers are built on it. The effective inner diameter of the front bed portion 3 is 1.6×4.5×0.8 meters, and the model of the coal injection gun 19 is 300 kilograms of coal injection per hour. The effective height of the inner material layer of the vertical furnace 11 is maintained at 3.5-4 meters, and the amount of pulverized coal injected is controlled so that the temperature of the Pall ring layer is 850-950° C., for example, 900° C. When the effective volume of the front bed is maintained at about 75% by opening the discharge port 2, add secondary coal continuously, s...

Embodiment 2

[0041] Raw material mass: Yuanming powder:white coal:water:catalyst with a weight ratio of 100:30:6:0.5, pressed into a raw material mass by rolling machine, and left for 12 hours. This embodiment adopts the same fixed furnace type as that of Embodiment 1. Maintain the effective height of the inner material layer of the vertical furnace 11 to be 3-3.5 meters, and the amount of pulverized coal injected is controlled so that the temperature of the Pall ring layer is in the range of 850---950 ° C, such as 880 ° C. When the effective volume of the front bed part 3 reaches about 75%, add secondary coal continuously. Based on the calorific value of the filter residue 85%, 6000 kcal of white coal is used, and the total coal consumption per ton of 60% soda sulfide reduction process is <0.75 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com