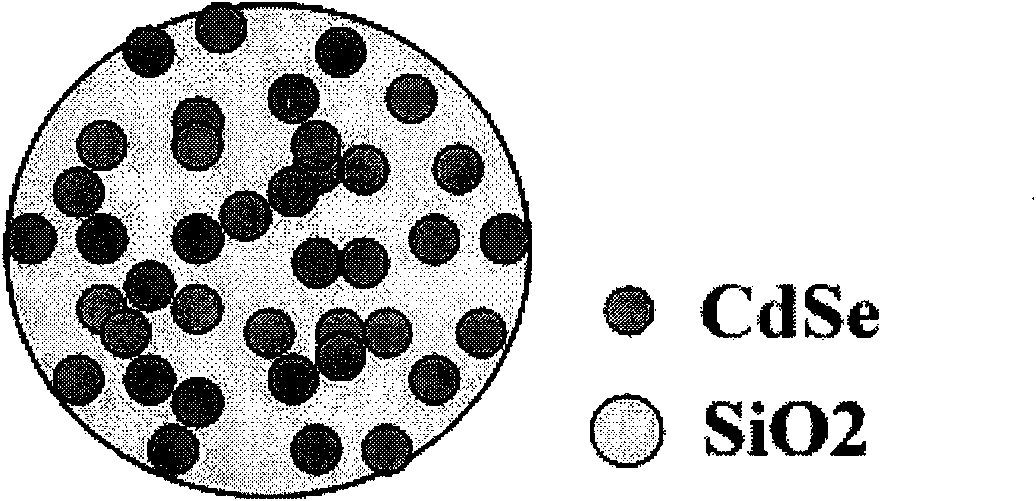

High fluorescence property nanometer composite microsphere and the production method thereof

A fluorescent performance, nano-microsphere technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low fluorescence intensity, low luminous efficiency of products, environmental pollution, etc., and achieve high fluorescence intensity, good application prospects, and excellent fluorescence performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

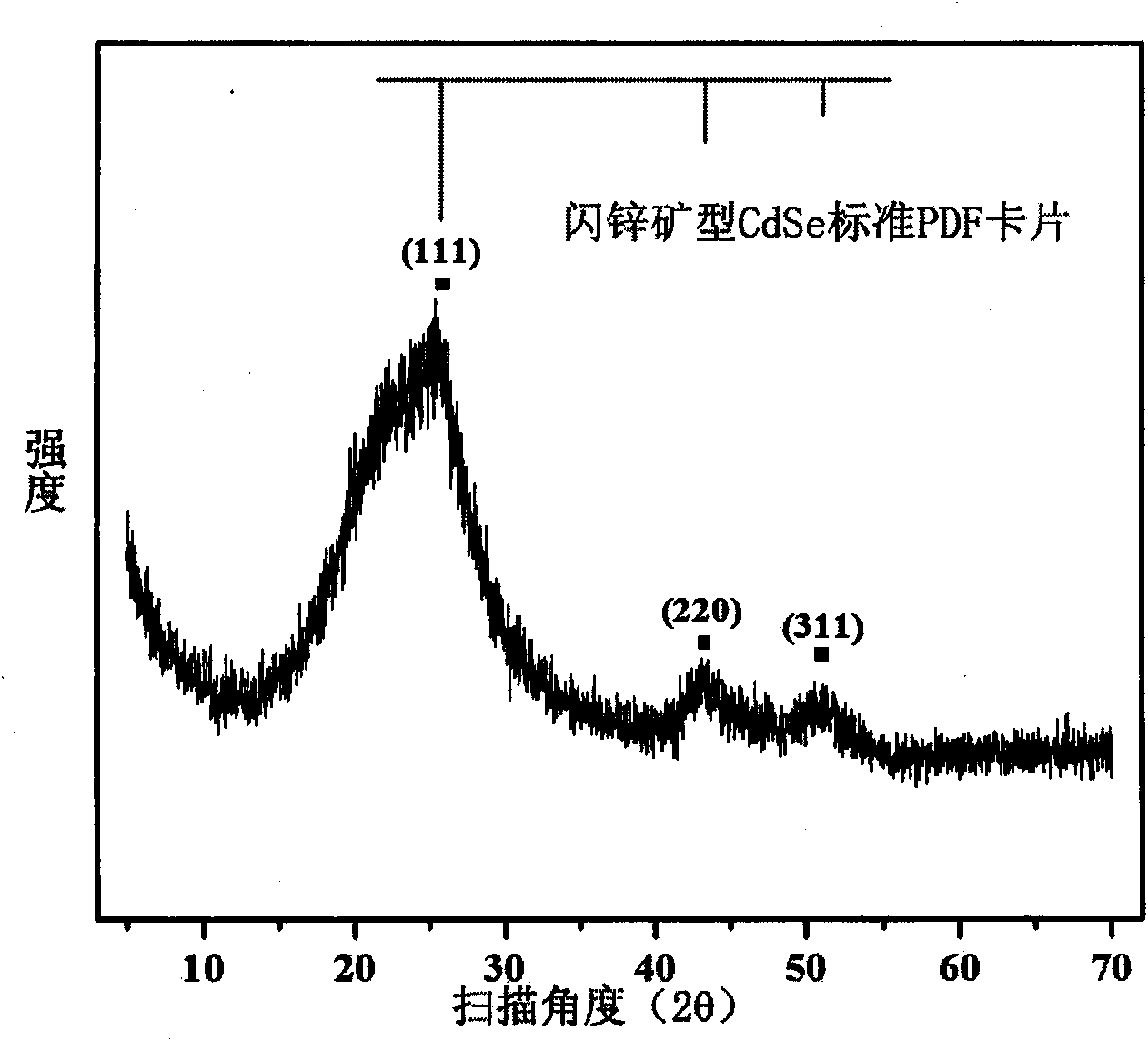

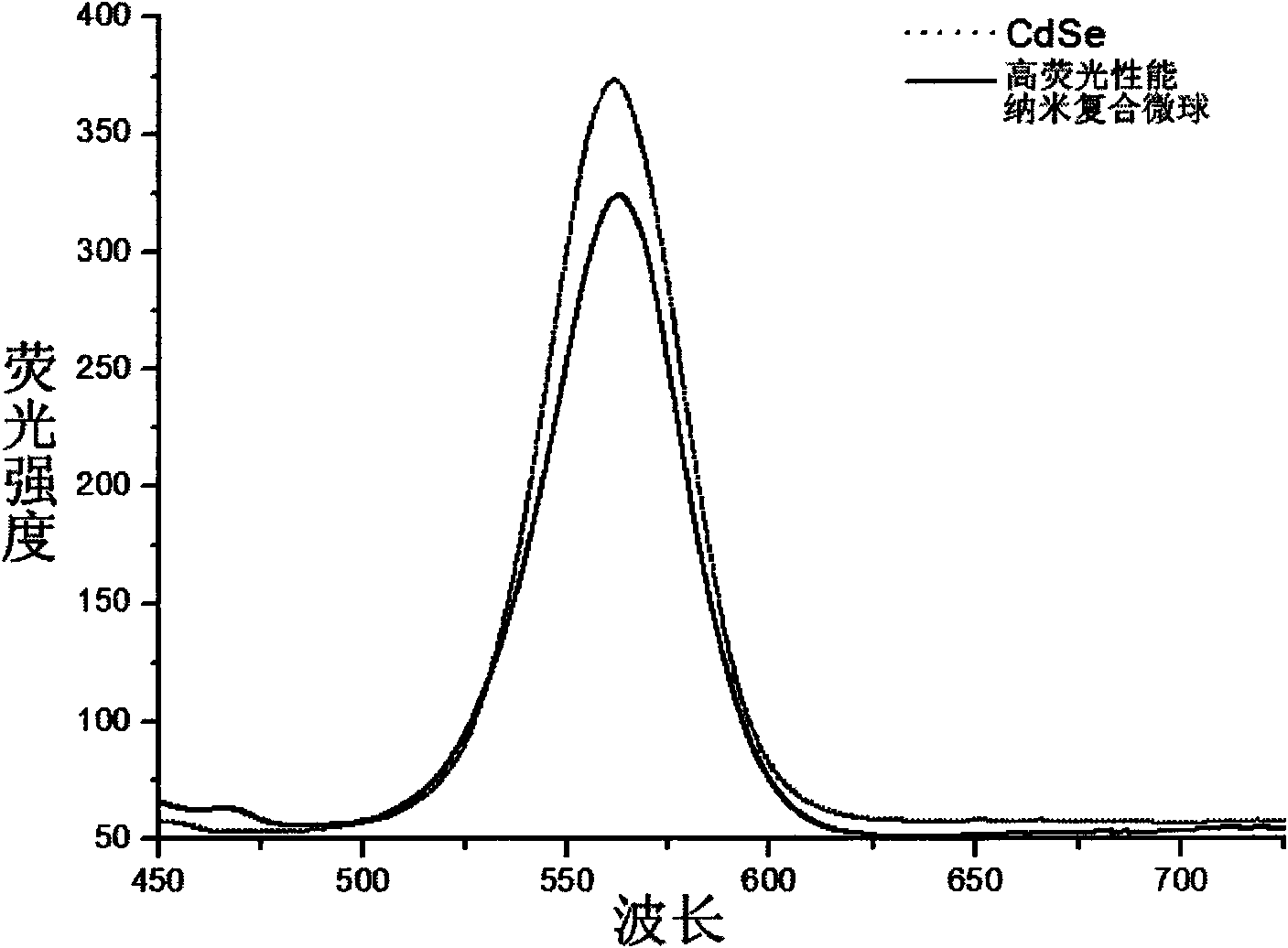

Embodiment 1

[0024] Embodiment 1: add 0.25g cadmium chloride powder in 500ml of deionized water, magnetically stir to obtain a colorless and clear cadmium chloride solution, then add 85ul of mercaptoacetic acid for processing, and form a white precipitate in the solution. Under the conditions, adjust the pH value to 8-12 with concentrated ammonia water, and continue stirring at a rotating speed of 500rpm until the solution becomes colorless and transparent to obtain a cadmium chloride solution with well-dispersed mercapto groups, and obtain liquid A; take 0.02g of selenium powder and 0.2 Mix 2g of sodium borohydride, add 2ml of deionized water, react under the protection of argon until the black selenium powder disappears completely, and add this liquid to liquid A, fully react at a speed of 500rpm to obtain a cadmium selenide precursor Put this precursor in an autoclave and react under the condition of 220°C for 2 hours to produce a water-soluble cadmium selenide quantum dot solution with ...

Embodiment 2

[0027] Embodiment 2: add 0.25g cadmium chloride powder in 500ml deionized water, magnetically stir to obtain a colorless and clear cadmium chloride solution, then add 85ul of mercaptoacetic acid for processing, and form a white precipitate in the solution. Under the conditions, adjust the pH value to 8-12 with concentrated ammonia water, and continue to stir at a speed of 500 rpm until the solution becomes colorless and transparent to obtain a cadmium chloride solution with well-dispersed mercapto groups, and obtain liquid A; take 0.032 g of tellurium powder and 0.2 Mix 2g of sodium borohydride, add 2ml of deionized water, and react under the protection of argon until the black tellurium powder disappears completely, and add this liquid into liquid A, and fully react at a speed of 500rpm to obtain a cadmium telluride precursor body; put this precursor in an autoclave for hydrothermal reaction at 220°C for 2 hours to obtain a water-soluble cadmium telluride quantum dot solution ...

Embodiment 3

[0030] Embodiment 3: add 0.25g cadmium chloride powder in 500ml deionized water, magnetically stir to obtain a colorless and clear cadmium chloride solution, then add 85ul of mercaptoacetic acid for processing, and form a white precipitate in the solution. Under the conditions, adjust the pH value to 8-12 with concentrated ammonia water, and continue stirring at a rotating speed of 500rpm until the solution becomes colorless and transparent to obtain a cadmium chloride solution with well-dispersed mercapto groups, and obtain liquid A; take 0.02g of selenium powder and 0.1 Mix 2g of sodium borohydride, add 2ml of deionized water, react under the protection of argon until the black selenium powder disappears completely, and add this liquid to liquid A, fully react at a speed of 500rpm to obtain a cadmium selenide precursor Put this precursor in an autoclave and react under the condition of 220°C for 2 hours to produce a water-soluble cadmium selenide quantum dot solution with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com