Magnetic nano-material extractant and preparation method thereof

A magnetic nanometer and magnetic nanoparticle technology, which is applied in the fields of microsphere preparation, inorganic material magnetism, chemical instruments and methods, etc., can solve the problem of difficulty in extracting target pollutants, difficulty in solid-phase extraction through the column, and the particle size of nanoparticles is too small. and other problems, to achieve the effect of fast extraction speed, strong surface adsorption, and short diffusion path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 : The preparation method of magnetic nano material extraction agent of the present invention

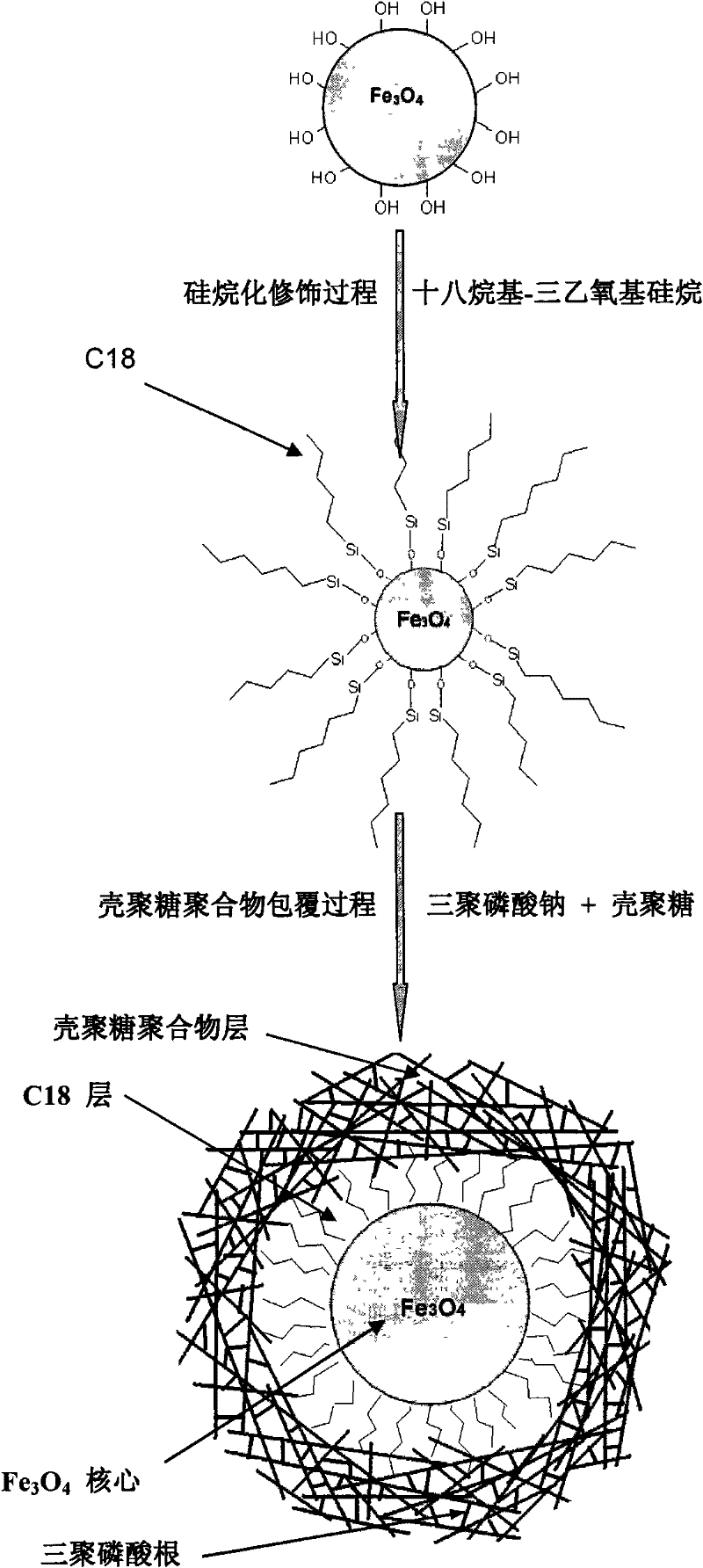

[0039] Chitosan polymer-coated Fe provided by the present invention 3 o 4 -C 18 The schematic diagram of the synthesis of magnetic nanomaterial extractant is as follows: figure 1 As shown, its specific preparation method can be divided into the following three steps:

[0040] First, prepare nano-iron oxide. 2.0g FeCl 3 ·6H 2 O and 5.2 g FeCl 2 4H 2 O and 0.85mL of concentrated hydrochloric acid were dissolved in 25mL of N 2 Deoxidized deionized water; under 80°C water bath and mechanical stirring, add the above solution dropwise to N 2 In the protected 250mL 1.5 (mol / L) NaOH aqueous solution, continue to pass N 2 Insulate and stir for 0.5 hours to react; after the reaction, use an external magnetic field to separate the prepared iron oxide magnetic nanoparticles.

[0041] Second, the preparation of Fe 3 o 4 -C 18 Magnetic Nanomaterials. will get Fe ...

Embodiment 2

[0043] Example 2 : The modification reagent optimization of preparation magnetic nano material extraction agent of the present invention

[0044] When preparing the magnetic nano-extractant, different doses of C 18 Modified by silylating reagent, coated with chitosan and sodium tripolyphosphate solution with different concentrations and proportions, the mass percentage and adsorption capacity of each part of the obtained extractant are different. Therefore, in this implementation, the above-mentioned C 18 The dosage of silylating agent and the concentration ratio of chitosan and sodium tripolyphosphate were optimized.

[0045] 1.C 18 Optimization of the dosage of silylating reagent

[0046] to Fe 3 o 4 Granules for C 18 During silanization modification, since the active hydroxyl groups on the particle surface are limited, the combination of C 18 The amount of silane groups is also limited. If the dosage is too small, the modified magnetic nanoparticles have fewer adso...

Embodiment 3

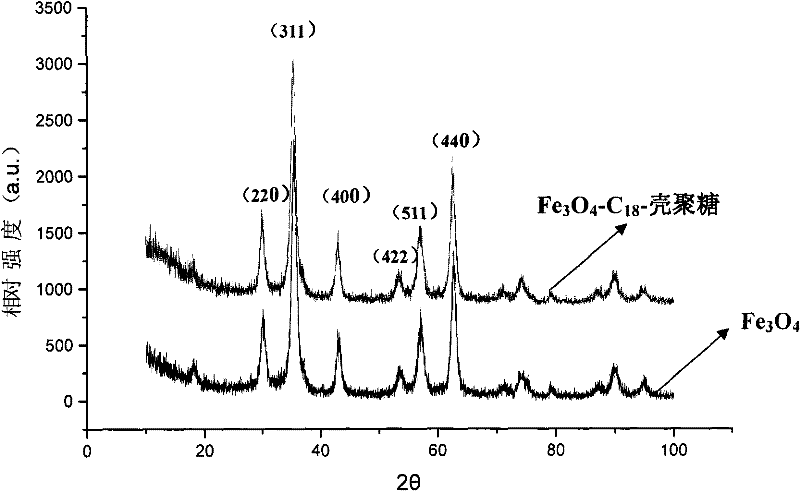

[0056] Example 3 : Structural characterization of magnetic nanomaterial extractant of the present invention

[0057] This embodiment is the structural characterization of the fourth group of magnetic nanomaterial extractants optimized in Example 2, specifically as follows:

[0058] 1. Specific surface area and pore volume

[0059]The specific surface area and pore volume of the magnetic nanoparticles were measured by a Gemini 2375V4.01 nitrogen adsorption BET specific surface area analyzer (Norcross, USA). For the measurement method and parameter settings, see IanJ.Bruce, et al, Journal of Magnetism and Magnetic Materials 284 (2004) 145-160. The result of measuring magnetic nanomaterial extractant of the present invention is: specific surface area is 90.3124 (m 2 / g); the pore volume is 0.361007(cm 3 / g).

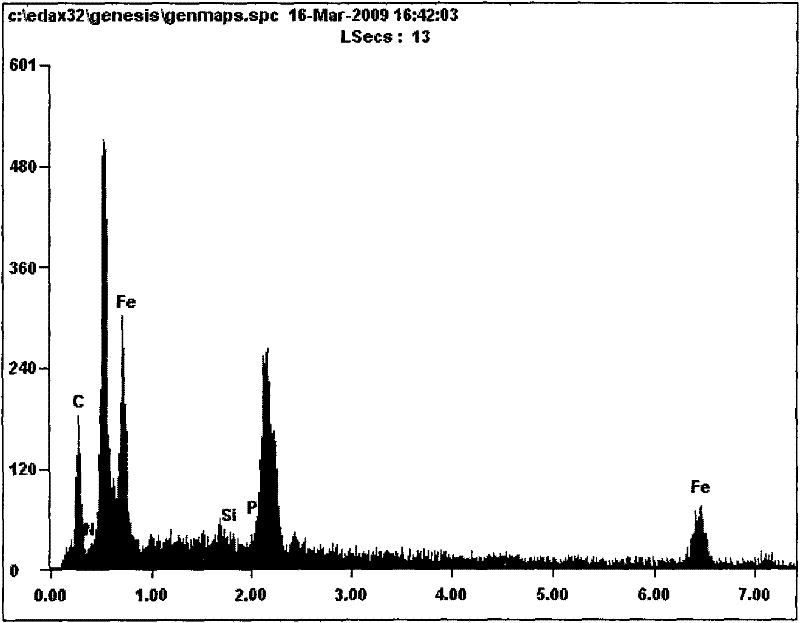

[0060] 2. EDX spectrum

[0061] Adopt DX-4 type X-ray energy spectrometer (Philips company) to measure the EDX energy spectrum figure of magnetic nanoparticle, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com