Cladding nanometer iron stable in air and preparation method thereof

A coated nano-iron technology, applied in the nanometer field, can solve problems such as not being fully developed, and achieve the effects of good contact, simple equipment, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

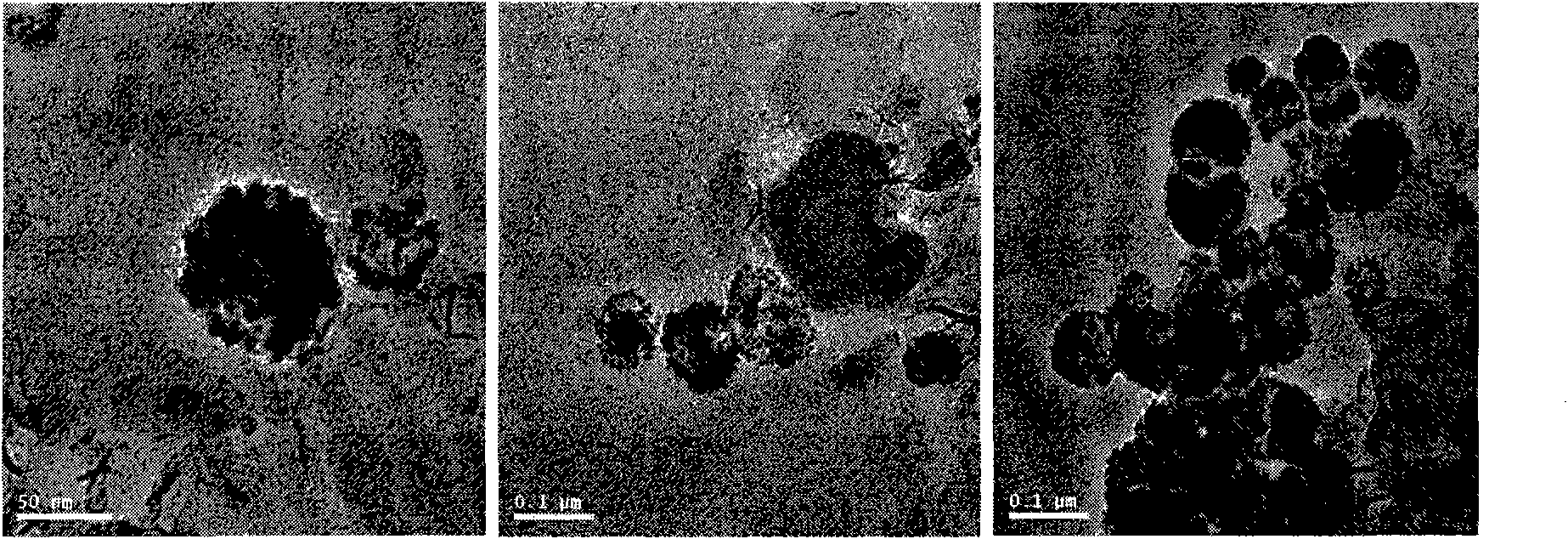

[0032] An air-stable coating type nano iron, which takes nano zero-valent iron particles as the core and is coated with polymethyl methacrylate on its surface. The preparation method includes the following steps:

[0033] (1). Preparation of microemulsion A;

[0034] ① Take 2g cetyltrimethylammonium bromide (CTAB), 1mL n-butanol, 2mL isooctane, and mix with 1mL methyl methacrylate (MMA) and 0.01g azobisisobutyronitrile (AIBN) Uniformly form mixed system A;

[0035] ②Then weigh out 0.002g FeSO 4 ·7H 2 Dissolve O into 2mL deionized water to form FeSO 4 Aqueous solution

[0036] ③Add FeSO to the mixed system A 4 Aqueous solution, ultrasonic dispersion for 1min, the system changed from turbid to clear, and FeSO with monomer and initiator added 4 Reverse microemulsion is microemulsion A.

[0037] (2). Preparation of microemulsion B;

[0038] ① Take 2g cetyltrimethylammonium bromide (CTAB), 1mL n-butanol, 2mL isooctane, and mix with 1mL methyl methacrylate (MMA) and 0.01g azobisisobutyr...

Embodiment 2

[0044] When preparing microemulsion B, NaBH is used 4 Replace KBH 4 That is, the others are the same as in Example 1.

Embodiment 3

[0046] An air-stable coating type nano iron, which takes nano zero-valent iron particles as the core and is coated with polymethyl methacrylate on its surface. The preparation method includes the following steps:

[0047] (1). Preparation of microemulsion A;

[0048] ① Take 8g cetyltrimethylammonium bromide (CTAB), 6mL n-butanol, 16mL isooctane, and mix with 2mL methyl methacrylate (MMA) and 0.02g azobisisobutyronitrile (AIBN) Uniformly form mixed system A;

[0049] ②Then weigh out 0.139g FeSO 4 ·7H 2 Dissolve O in 10mL deionized water to form FeSO 4 Aqueous solution

[0050] ③Add FeSO to the mixed system A 4 Aqueous solution, ultrasonically dispersed for 2 minutes, the system changed from turbid to clear, and FeSO with monomer and initiator added 4 Reverse microemulsion is microemulsion A.

[0051] (2). Preparation of microemulsion B;

[0052] ① Take 8g cetyltrimethylammonium bromide (CTAB), 6mL n-butanol, 16mL isooctane, and mix with 2mL methyl methacrylate (MMA) and 0.02g azobis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com