External cavity type multiple-active region photon crystal vertical cavity surface transmission semiconductor laser device

A vertical cavity surface emission and photonic crystal technology, applied in the field of optoelectronics, can solve the problems of increased threshold current, large light emitting area, and large series resistance, etc., and achieve the goals of reducing series resistance, increasing light emitting area, and strong anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

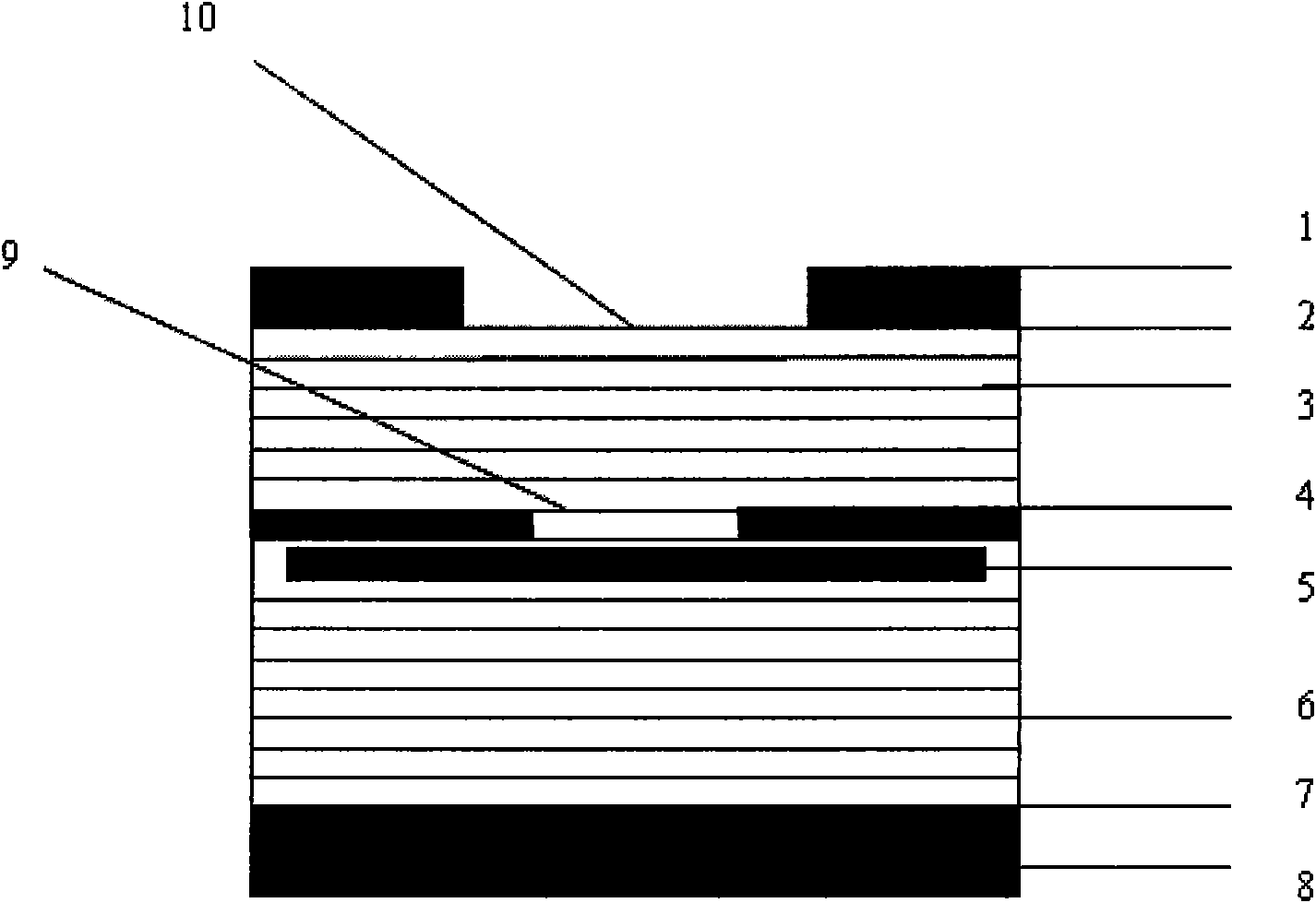

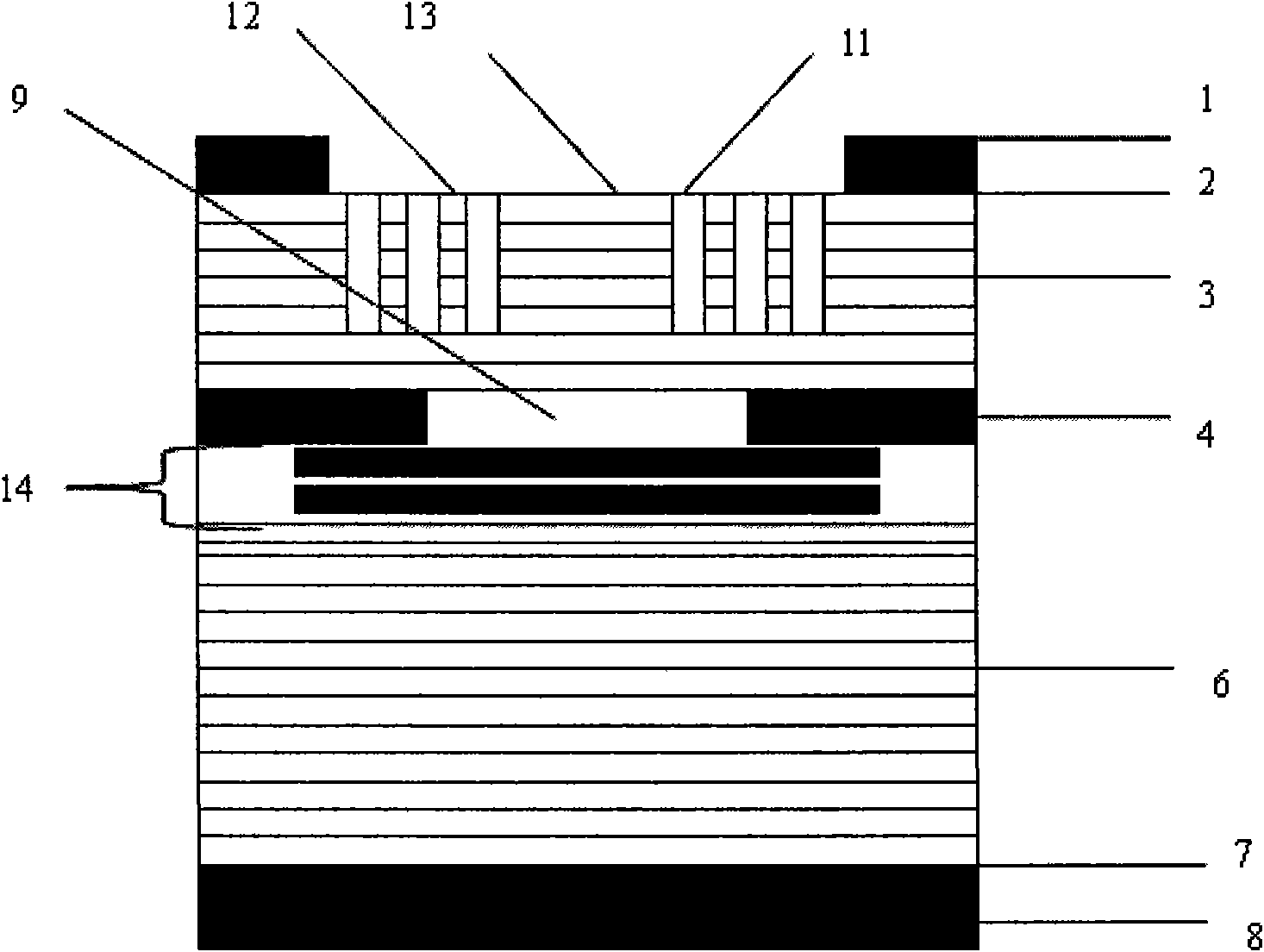

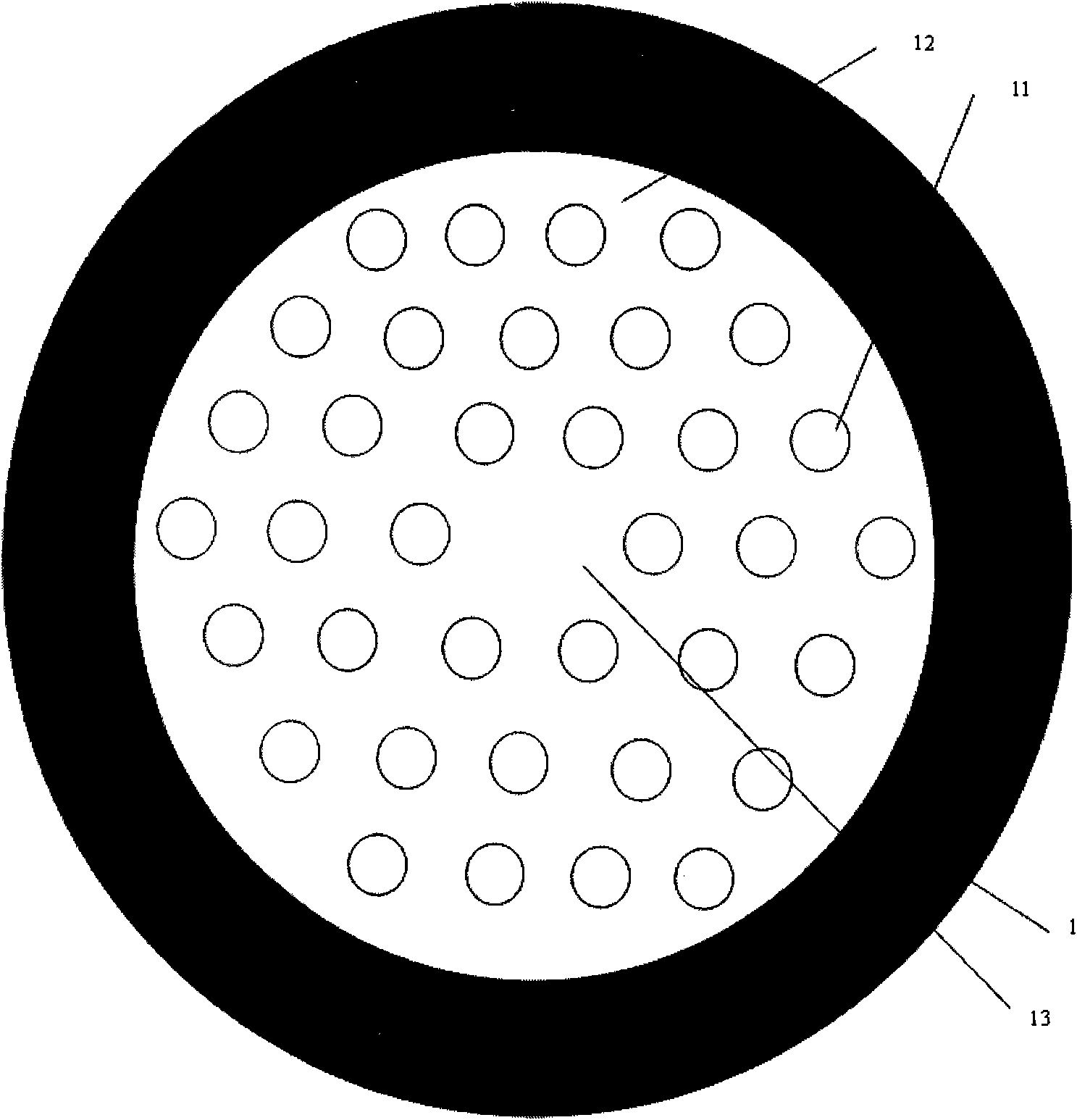

[0027] Specific implementation methods (taking the wavelength 850nm as an example)

[0028] 1. Pass in N + The substrate 7 was obtained by growing on a GaAs substrate of type 1, and then a 0.3 micron GaAs buffer layer was grown on the substrate by MOCVD method, and then N + al 0.1 Ga 0.9 As (60nm doping concentration 3×10 18 cm -3 ) and n + al 0.9 Ga 0.1 As (68.19nm doping concentration 3×10 17 cm -3 ) composed of 28 cycles of the lower DBR6, In 0.18 al 0.12 Ga 0.7 As and Al 0.22 Ga 0.78 AS composed of single active region 5 heavily doped N + GaAs and P + Multiple active regions (three active regions) cascaded with GaAs reverse tunnel junctions 14, Al 0.98 Ga 0.02 As (30nm doping concentration 1×10 18 cm -3 ) oxidation limiting layer 4,, Al 0.1 Ga 0.9 As (60nm doping concentration 3×10 18 cm -3 ) and Al 0.9 Ga 0.1 As (68.19nm doping concentration 3×10 18 cm -3 ) consisting of 24 cycles of upper DBR3, Al 0.1 Ga 0.9 As heavily doped ohmic contact lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com