Method for preparing modified polyaluminium chloride flocculating agent by waste molecular sieve

A technology of polyaluminum chloride and waste molecular sieve, which is used in the removal of aluminum chloride, aluminum halide, solid waste, etc. body formation, the effect of overcoming poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

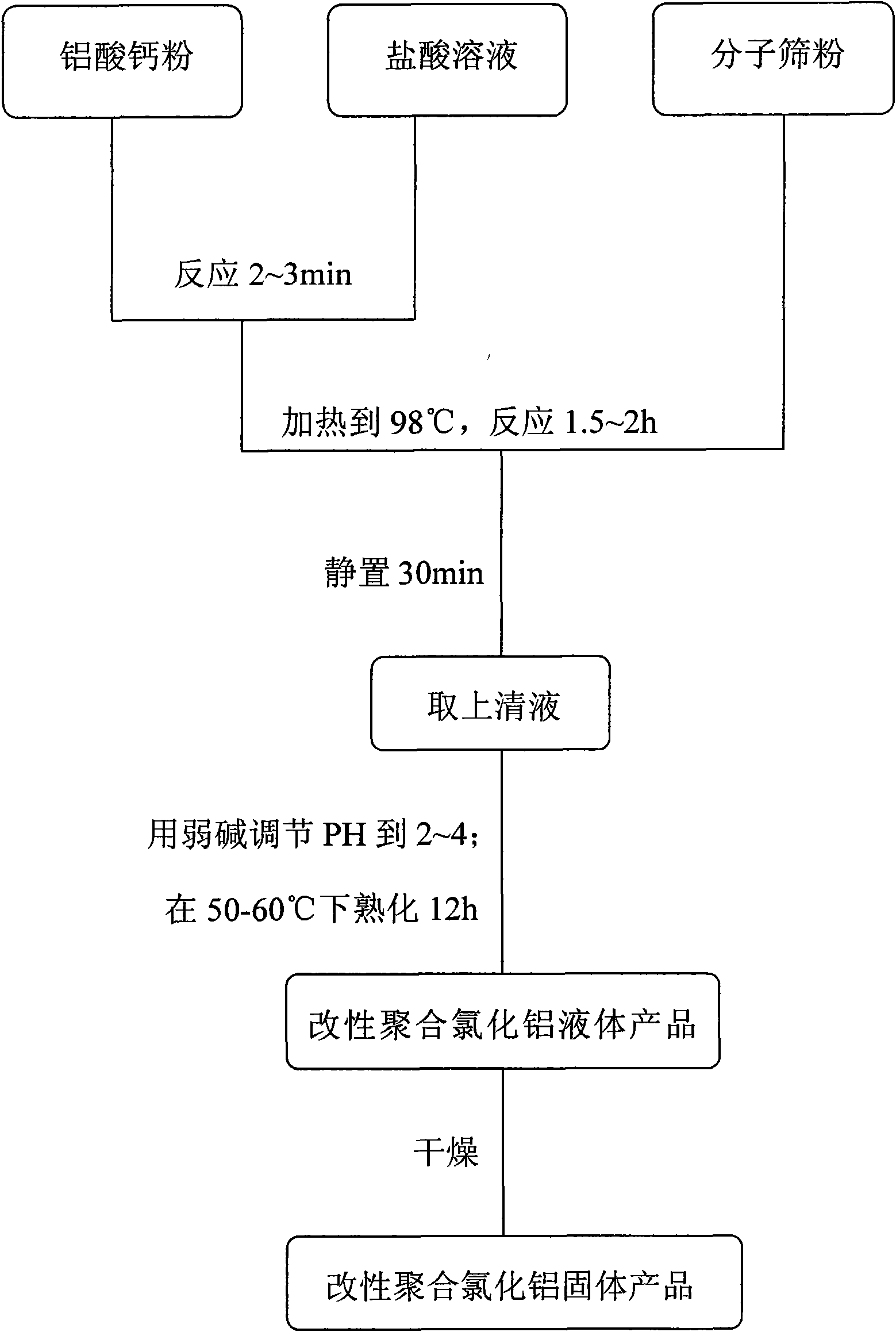

Method used

Image

Examples

Embodiment 1

[0022] Activation steps of waste molecular sieves:

[0023] In the petroleum industry, after a period of use, the catalytic performance has declined, but the main components of the molecular sieve have basically remained unchanged, and washed with a large amount of water. drying. Place it in a muffle furnace and heat it at a temperature of about 550°C for about 6 hours. After cooling, place the molecular sieve in a desiccator and it can be used.

[0024] Preparation steps:

[0025] 1. Break the activated molecular sieve, and then sieve it with a 60-mesh sieve to obtain a molecular sieve powder with a size above 60 mesh. Sieve commercially available industrial-grade calcium aluminate with a 60-mesh sieve to obtain calcium aluminate powder with a size above 60 mesh.

[0026] 2. Weigh 20 grams of molecular sieve powder and 20 grams of calcium aluminate powder.

[0027] 3. Prepare 100 ml of hydrochloric acid solution with a volume fraction of 20%.

[0028] 4. First add hydro...

Embodiment 2

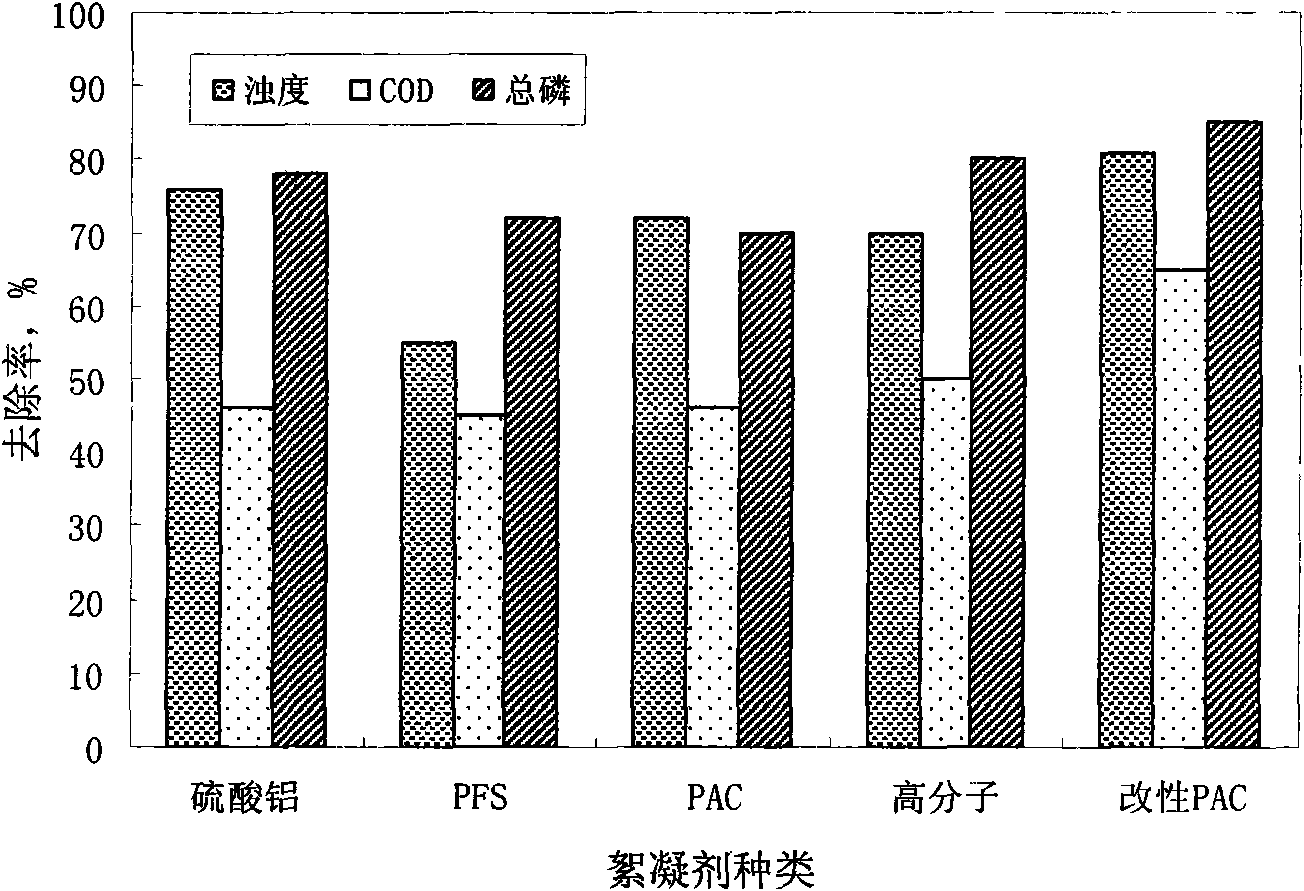

[0030] The modified polyaluminum chloride flocculant of Example 1 was used to treat low-temperature and low-turbidity sewage. The experimental water was taken from the sewage of the sewage plant and the effluent after biochemical treatment. Modified PAC (polyaluminum chloride) of the present invention and other four kinds of coagulants have been compared, confirmed the superiority of the processing effect of the invention (please see figure 2 ).

[0031] The water quality of the sewage plant's domestic sewage after biochemical treatment is as follows: COD is 60-140mg / L, TP is 2-6mg / L, and turbidity is 10-80NTU. Enhanced coagulation was used for advanced treatment (the average water temperature was 6°C, and the pH of the water sample was about 7.5). The COD, TP and turbidity of the water samples were measured respectively, and different coagulants were used for advanced treatment of the biochemical effluent. The results are compared as follows :

[0032] The modified polyalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com