Antifungal protein, method for preparing same and application thereof

An antifungal protein and seed technology, applied in the preparation method of peptides, botanical equipment and methods, applications, etc., can solve the problems of difficult amplification of the preparation system, retention, and inability to achieve mass production, and achieve high purification multiples and purification steps little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

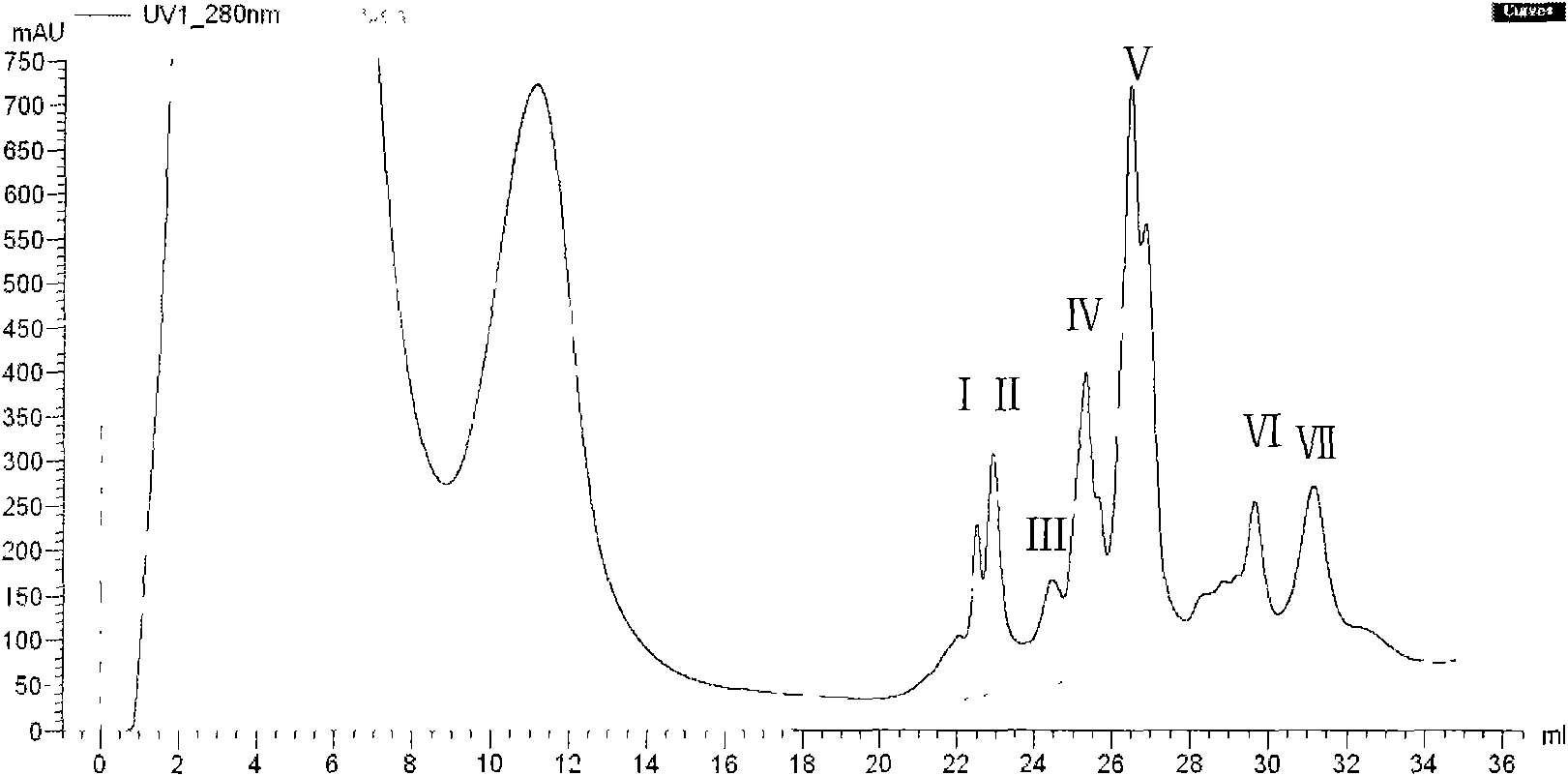

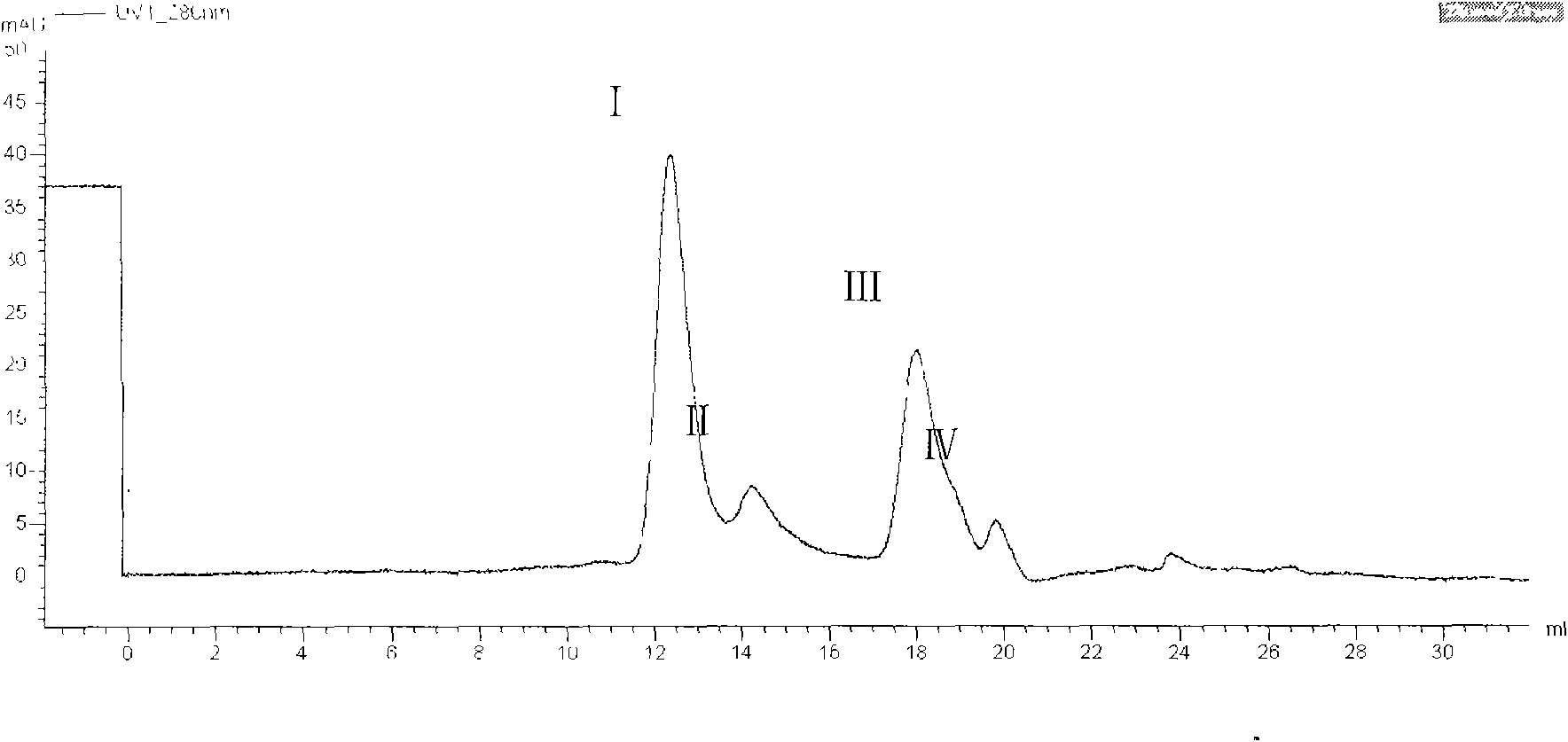

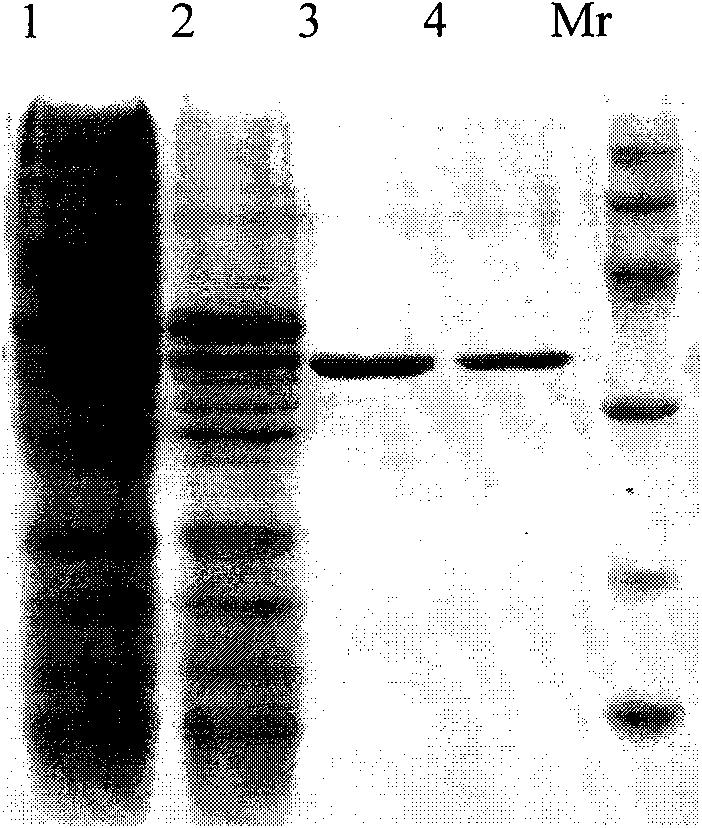

[0030] Embodiment 1: Preparation of buckwheat seed antifungal protein

[0031] Naked oats seeds come from the naked oats production area of Datong City, Shanxi Province. Take 100g of naked oats seeds harvested in the same year, dry them at low temperature, grind them in a seed grinder, pass through a 0.2mm aperture sieve, add 300ml of acetone, and store them at 4°C Stir skim for 3 hours. Suction filtration under reduced pressure, discard the acetone, collect the filter cake, add a small amount of ether to stir, vacuum suction filtration, discard the ether, collect the filter cake, dry at low temperature, and the obtained powder is oatmeal degreased powder.

[0032] Take 20g of oatmeal defatted powder, add 200ml of extraction buffer, the buffer formula is: 20mM Tris-HCl, pH 8.0. Stir and extract at 4°C for 6 hours, centrifuge at 12000rpm to discard the precipitate, add ammonium sulfate to the supernatant to 80% saturation, stir and salt out at 4°C for 6 hours, centrifuge at ...

Embodiment 2

[0038]Example 2 The effect of naked oat seed antifungal protein on the growth inhibition of Trichoderma viride and its dose-dependent experiment

[0039] Prepare the PDA medium, plant the test strain Trichoderma reesei in the center of the medium, cultivate it at 28°C until the diameter of the mold colony reaches 1-2cm, and place a sterilized Oxford cup on the periphery of the colony, 1cm away from the edge of the colony , the sample group (containing the target protein) and the control group (the buffer with the same conditions) were sterilized by filtration with a 0.22 μm microporous membrane, and 200 μl of the prepared protein sample or the same volume of buffer solution was added to the Oxford cup as a control, and covered with a ceramic Tile cover, pre-diffusion at 4°C for 24h, transfer the medium to a 28°C incubator and culture for 72h, then observe the growth of the colony.

[0040] Such as Figure 4 -A shows: set up four Oxford cups, among which 1 is the control group...

Embodiment 3

[0041] Example 3 The effect of oat seed antifungal protein on the growth inhibition of white rot fungus and its dose-dependent experiment

[0042] Prepare the PDA medium, plant the white rot fungus (Panus conchatus) of the test strain in the center of the medium, cultivate it at 28°C until the diameter of the mold colony reaches 1-2cm, and place a sterilized Oxford cup on the periphery of the colony, 1cm away from the edge of the colony , the sample group (containing the target protein) and the control group (the buffer with the same conditions) were sterilized by filtration with a 0.22 μm microporous membrane, and 200 μl of the prepared protein sample or the same volume of buffer solution was added to the Oxford cup as a control, and covered with a ceramic Tile cover, pre-diffusion at 4°C for 24h, transfer the medium to a 28°C incubator and culture for 72h, then observe the growth of the colony.

[0043] Such as Figure 4 -B shows: three Oxford cups are set up, among which 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com