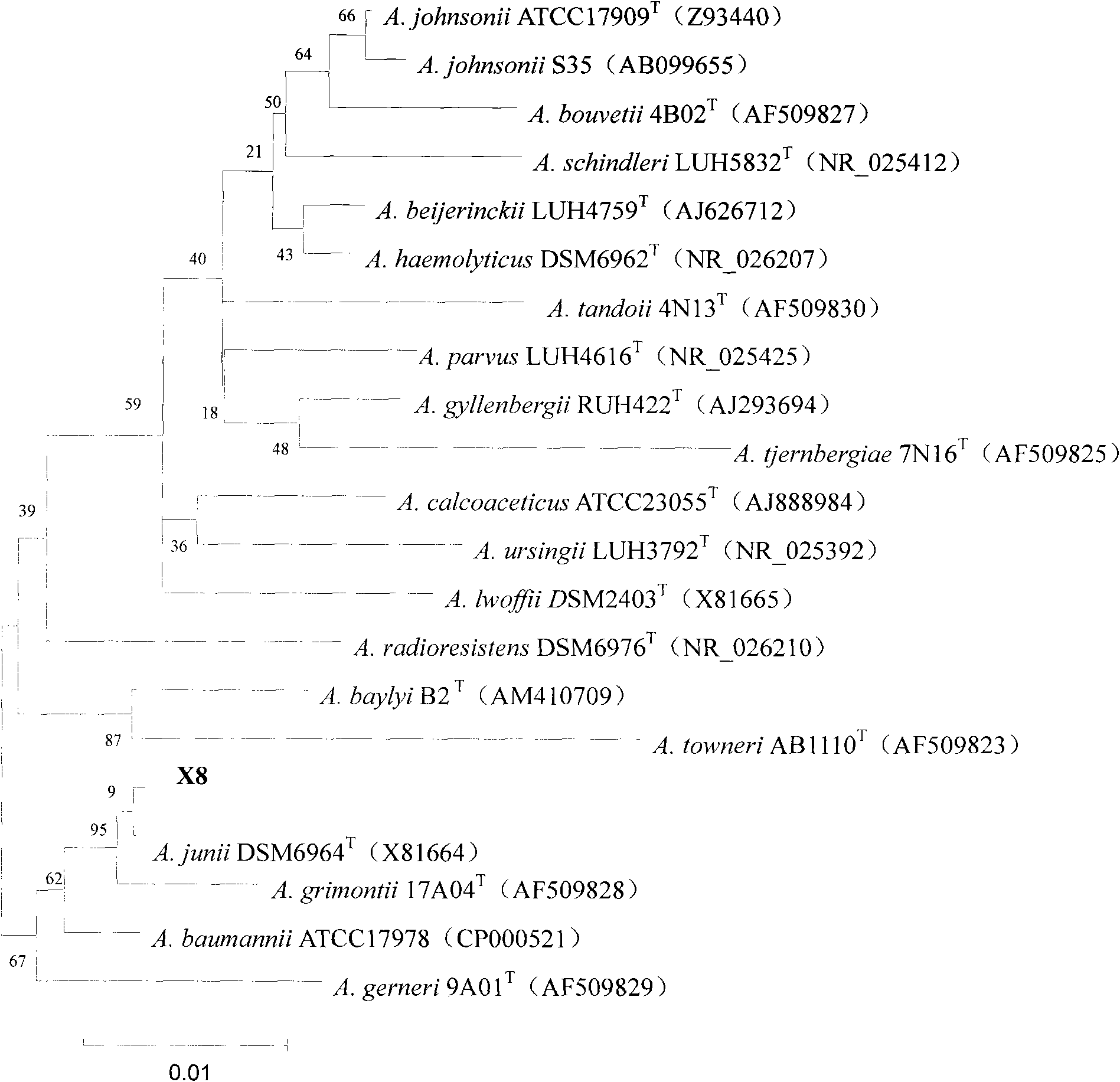

Acinetobacter juni. X8 and application thereof in preparing algin lyase

A technology of Acinetobacter angnei and alginate lyase, which is applied in the direction of lyase, bacteria, and microorganism-based methods, and can solve the problems of difficult separation, poor storage stability, and low production of alginate lyase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Enrichment, domestication and isolation and screening of strains

[0049] Inoculate the spoiled Hijiki leaves and bacterial suspension into a 500mL Erlenmeyer flask filled with 100mL No. 1 medium, and enrich and culture them at 30°C and 180rpm for 72 hours. If the growth is good, pipette 5mL of the culture medium to inoculate Cultivate in No. 2 medium at 30°C and 180 rpm for the same time, otherwise continue to inoculate into No. 1 medium for cultivation. Repeat this for many times, and then move to the culture medium with sodium alginate as the only carbon source for separation and screening.

[0050] The formula of No. 1 and No. 2 liquids and separation and screening medium is as follows:

[0051] ① Medium 1: 0.5% sodium alginate, 0.4% peptone, 2.5% NaCl, 1.0% MgSO 4 ·7H 2 O, 0.2%K 2 HPO 4 ·3H 2 O, 0.001% FeSO 4 ·7H 2 O, the solvent is water, the pH value is 7.2 to 7.4;

[0052] ② Medium 2: 0.5% sodium alginate, 0.5% (NH 4 ) 2 SO 4 , 2.5% NaCl, ...

Embodiment 2

[0055] Embodiment 2: Preparation of alginate lyase enzyme liquid

[0056] The preparation method of alginate lyase is as follows:

[0057] (1) Inoculate the strain Acinetobacter juni X8 stored in a slant test tube into an isolation medium plate, culture for 48-72 hours, and transfer several times in this way to activate the strain; the isolation medium is prepared according to the following composition: sodium alginate 5g, (NH 4 ) 2 SO 4 5g, NaCl 25g, K 2 HPO 4 ·3H 2 O2g, MgSO 4 ·7H 2 O 1g, 20g agar, make up to 1000mL with water, pH 7.2-7.4, heat to dissolve the agar, cool to get a plate;

[0058] (2) The activated strain is inoculated into a 250mL Erlenmeyer flask containing 50mL liquid seed medium, cultivated at 30°C and 150rpm for 8h to obtain a seed liquid; the liquid seed medium formula is: 0.5% sodium alginate, 0.5 %(NH 4 ) 2 SO 4 , 2.5% NaCl, 0.2% K 2 HPO 4 ·3H 2 O, the solvent is water, pH7.5;

[0059] (3) Inoculate 1.0 mL of seed liquid into a 250 mL E...

Embodiment 3

[0068] Embodiment 3: Preparation of fucoidan oligosaccharides

[0069]The preparation process of alginate oligosaccharides is as follows: add 1mL 0.75% (w / w) alginate substrate solution, 1mL 0.1moL / L pH7.5 sodium phosphate buffer solution, and 1mL enzyme solution prepared in Example 2 to the test tube in sequence , and react at 40.0°C for 5 minutes to obtain unpurified alginate oligosaccharides. As determined by the 3,5-dinitrosalicylic acid method, about 1395 μg of alginate can be obtained per mg of purified alginate lyase Fucoidan oligosaccharides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com