High dirt resistance emulsion paint and preparation method and application thereof

A technology of stain resistance and latex paint, applied in the field of coatings, can solve the problems of poor stain resistance of latex paint, and achieve the effects of low water absorption, excellent comprehensive performance and high stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

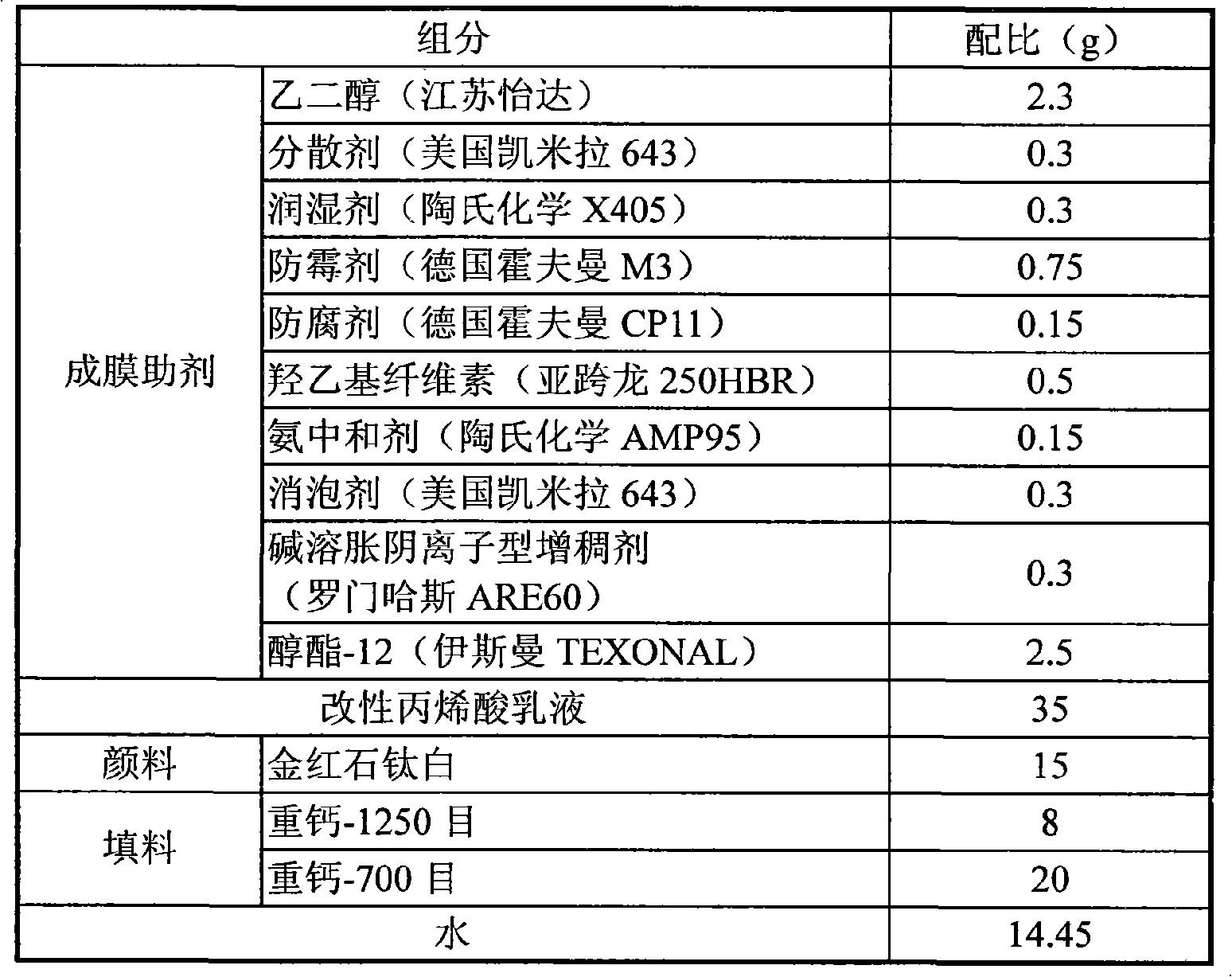

Examples

Embodiment 1

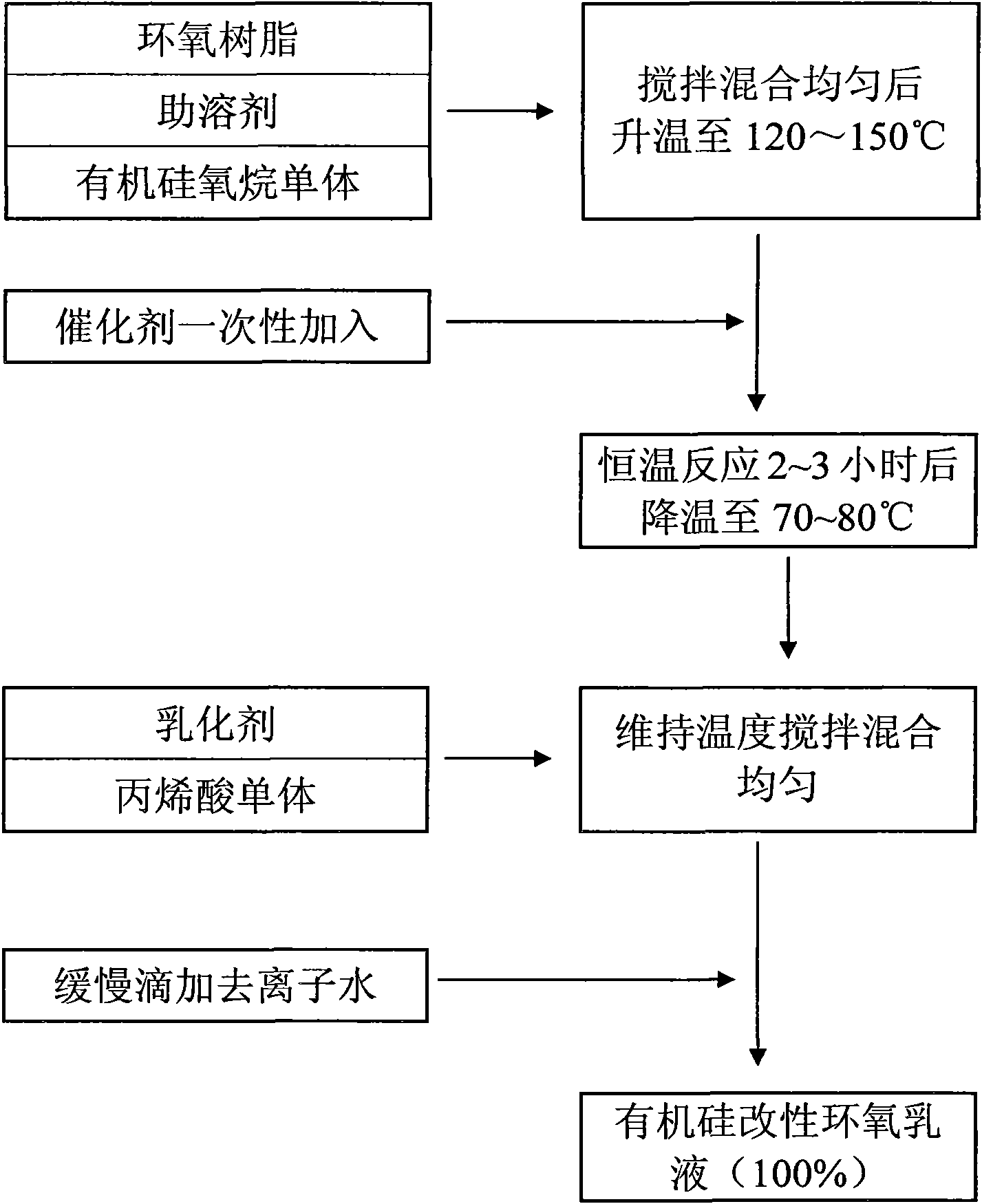

[0057] (1) Preparation of Silicone Modified Epoxy Resin Emulsion

[0058] as attached figure 1 As shown, add 40g of bisphenol A type epoxy resin E-44 (Guangzhou Dongfeng Chemical Industry Co., Ltd.) to a 1000ml four-necked flask equipped with a thermometer, condenser and stirrer (the average relative molecular weight of this resin measured by GPC is about 600 ~700), 10g of ethylene glycol monopropyl ether and 2g of vinyltriethoxysilane. Stirring was started and the temperature was raised to 130°C. After the resin was dissolved, 0.04g of tetraethylammonium bromide was added, followed by reaction at 130°C for 3h. After the reaction, cool down to 75°C, add 200g MMA, 180g BA, 20g MAA, 10g OP-10, 18g MS-1 and 4g DBS. 516 g of deionized water was slowly added dropwise, and the dropwise addition was completed within 2 hours. A silicone-modified epoxy resin emulsion with a solid content of 47.4% and an organic solvent content of 1% was obtained;

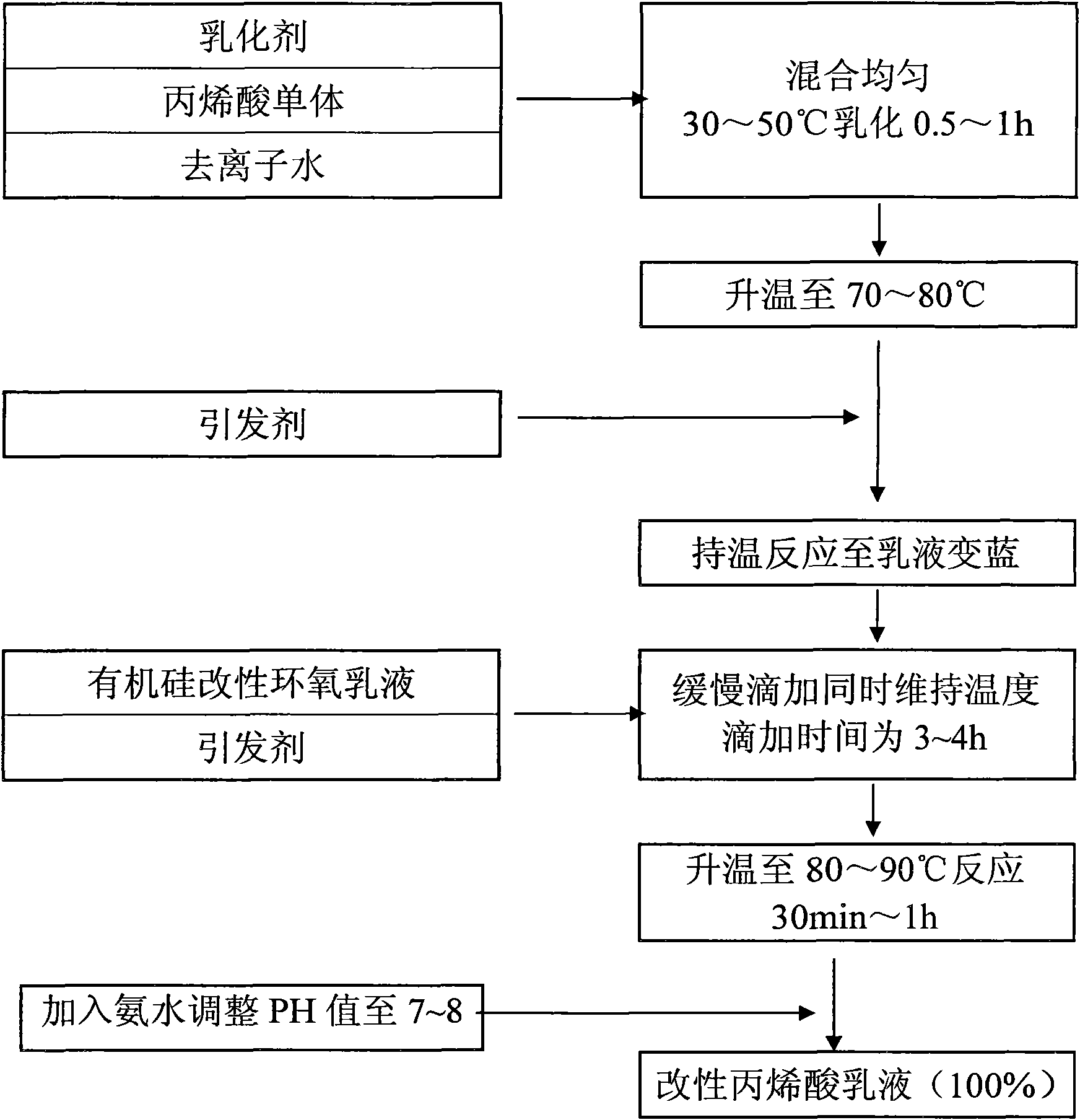

[0059] (2) Preparation of modifie...

Embodiment 2

[0080] (1) Preparation of Silicone Modified Epoxy Resin Emulsion

[0081] Add 60g of bisphenol F type epoxy resin (GELR-170) (Hongchang Electronic Materials Co., Ltd.), 8g of propylene glycol methyl ether and 2.5g of Z-6032 in the 1000ml four-necked flask equipped with thermometer, condenser and stirrer (Dow Corning Corporation). Start stirring and raise the temperature to 120°C. After the resin is dissolved, add 0.03g of tetramethylammonium chloride, and then react at 120°C for 2h. After the reaction, the temperature was lowered to 70°C, and 175g of MMA, 170g of BA, 15g of MAA, 15g of OP-10, 19g of MS-1 and 2g of DBS were added. 533.5 g of deionized water was slowly added dropwise, and the dropwise addition was completed within 3 hours. A silicone-modified epoxy resin emulsion with a solid content of 45.9% and an organic solvent content of 0.8% was obtained;

[0082] (2) Preparation of modified acrylic emulsion

[0083] Add 0.5g OP-10, 1g MS-1, 0.5g DBS, 20g MMA, 18g BA, ...

Embodiment 3

[0094] (1) Preparation of Silicone Modified Epoxy Resin Emulsion

[0095] Add 30g of bisphenol A type epoxy resin (GELR-134) (Hongchang Electronic Materials Co., Ltd.), 5g of ethylene glycol methyl ether and 1gZ- 6040 (Dow Corning Corporation). Start stirring and raise the temperature to 140°C. After the resin is mixed evenly, add 0.05g of n-butyltriphenylphosphine, and then react at 150°C for 3h. After the reaction, the temperature was lowered to 80°C, and 205g of MMA, 205g of BA, 15g of MAA, 15g of OP-10, 18g of MS-1 and 2g of DBS were added. 504 g of deionized water was slowly added dropwise, and the dropwise addition was completed within 3 hours. A silicone-modified epoxy resin emulsion with a solid content of 49.1% and an organic solvent content of 0.5% was obtained;

[0096] (2) Preparation of modified acrylic emulsion

[0097]Add 1g OP-10, 1.5g MS-1, 0.5g DBS, 15g MMA, 13g BA, 2g HEMA and 197.5g deionized water into a 1000ml four-neck flask at one time, emulsify at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com