Method for preparing transmittance grating

A technology of transmission grating and photoresist, which is applied in the direction of diffraction grating, photomechanical equipment, photoplate making process of pattern surface, etc., can solve the problems of poor performance of transmission grating, achieve excellent ability to resist harsh use environment, excellent thermal The effect of improving stability and dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

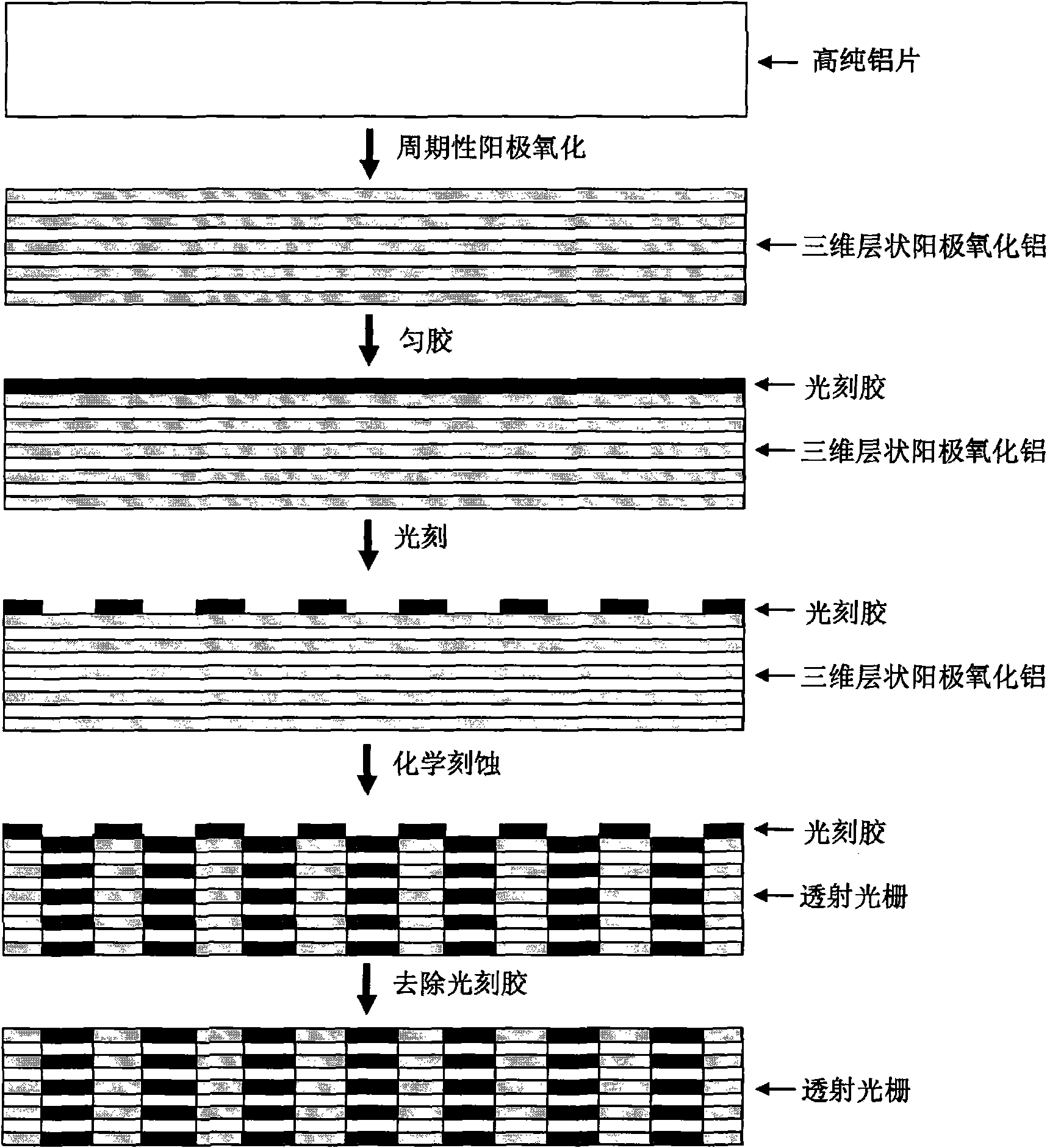

[0019] The transmission grating was prepared by the following method, as figure 1 Shown:

[0020] Step 1, using high-purity aluminum flakes with a purity of 99.999% as raw material, using the method reported in the published literature [Chemistry Letters, 35 (2006) 1336; Nanotechnology, 18 (2007) 365601] to carry out the periodicity of the aluminum flakes Oxidation, the oxidation parameters are: the electrolyte is 0.3Mol / L oxalic acid, the oxidation temperature is 15°C, the oxidation cycle time is 210S, the number of oxidation layers is 10 layers, and the layer distance is 300nm; a three-dimensional layer with a thickness of 3μm is obtained Porous alumina film with periodic structure;

[0021] Step 2, homogenizing: the obtained porous alumina film with a thickness of 3 μm and a three-dimensional layered periodic structure is washed with absolute ethanol and dried, and a layer of thickness of 1 micron is covered on the porous alumina film with a homogenizer photoresist;

[0...

Embodiment 2

[0028] The transmission grating was prepared by the following method:

[0029] Step 1, using high-purity aluminum flakes with a purity of 99.999% as a raw material, using the method reported in the published literature [ChemistryLetters, 35 (2006) 1336; Nanotechnology, 18 (2007) 365601] to carry out periodic oxidation of aluminum flakes, Oxidation parameters are: the electrolyte is 0.3Mol / L oxalic acid, the oxidation temperature is 10°C, the oxidation cycle time is 1000S, the number of oxidation layers is 10, and the interlayer distance is 2 μm; a three-dimensional layered period with a thickness of 20 μm is obtained Porous aluminum oxide film with strong structure;

[0030] Step 2, homogenizing: the obtained layered porous alumina film with a thickness of 20 μm is washed with absolute ethanol and dried, and a layer of photoresist with a thickness of 1 micron is covered on the porous alumina film by a homogenizer;

[0031] Step 3, photolithography: bake the layered porous alu...

Embodiment 3

[0035] Step 1, using high-purity aluminum flakes with a purity of 99.999% as a raw material, using the method reported in the published literature [ChemistryLetters, 35 (2006) 1336; Nanotechnology, 18 (2007) 365601] to carry out periodic oxidation of aluminum flakes, The parameters of oxidation are: the electrolyte is 0.3Mol / L oxalic acid, the oxidation temperature is 10°C, the oxidation cycle time is 150S, the number of oxidation layers is 100, and the interlayer distance is 200nm; Porous aluminum oxide film with strong structure;

[0036]Step 2, homogenizing: the obtained layered porous alumina film with a thickness of 20 μm is washed with absolute ethanol and dried, and then covered with a layer of photoresist with a thickness of 1 micron on the porous alumina film using a homogenizer ;

[0037] Step 3, photolithography: the layered porous alumina film covered with photoresist is baked at 90°C for 3 minutes, and then photolithography is performed after cooling in air for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com