Preparation method of chitosan-silicon dioxide compound hollow microballoon and application thereof

A technology of hollow microspheres and silicon dioxide, applied in the field of molecular sieves and carriers, can solve the problems of complex preparation process, etc., and achieve the effect of high mechanical strength, good stability, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

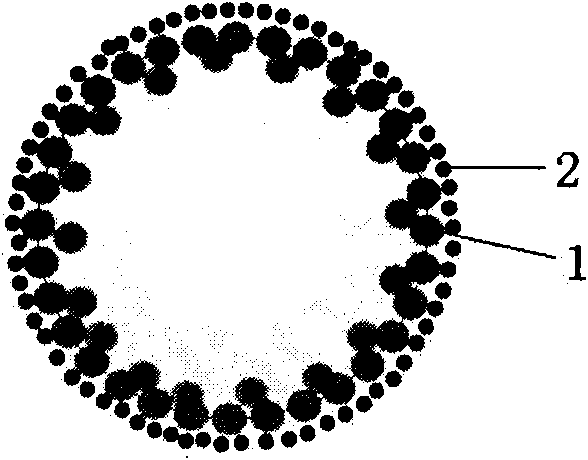

[0021] Firstly, hollow microspheres of chitosan-polyacrylic acid were prepared. Dissolve 0.25 g of chitosan and 0.12 g of acrylic acid in 25 mL of distilled water. After they are completely dissolved, the temperature is raised to 80° C., and 0.05 g of potassium persulfate is added to initiate the polymerization of acrylic acid. When the system appears milky white, the system is cooled to room temperature, and then the glutaraldehyde of 0.1 mL is added to selectively cross-link chitosan to obtain the emulsion of chitosan-polyacrylic acid hollow microspheres, which can be referred to the applicant's Prior application.

[0022] Take the newly prepared chitosan-polyacrylic acid emulsion 2.5mL and mix it with an equal volume of 2M ammonia water, and let it stand for 48 hours. Dissolve 520 µl of tetraethyl orthosilicate in 2 mL of ethanol. The alkaline chitosan-polyacrylic acid emulsion was slowly added dropwise to the ethanol solution of tetraethylorthosilicate. Stir at room tem...

Embodiment 2

[0025] Take 2.5 mL of the newly prepared chitosan-polyacrylic acid emulsion, adjust the pH of the emulsion to 3 with 2M acetic acid, and let it stand for 48 hours. Dissolve 520 microliters of ethyl orthosilicate in 2 mL of ethanol. The acidic chitosan-polyacrylic acid emulsion was slowly added dropwise to the ethanol solution of tetraethylorthosilicate. Stir at room temperature for 24 hours, then place it at 50° C. for 24 hours, filter and centrifuge to obtain chitosan-silicon dioxide composite hollow microspheres.

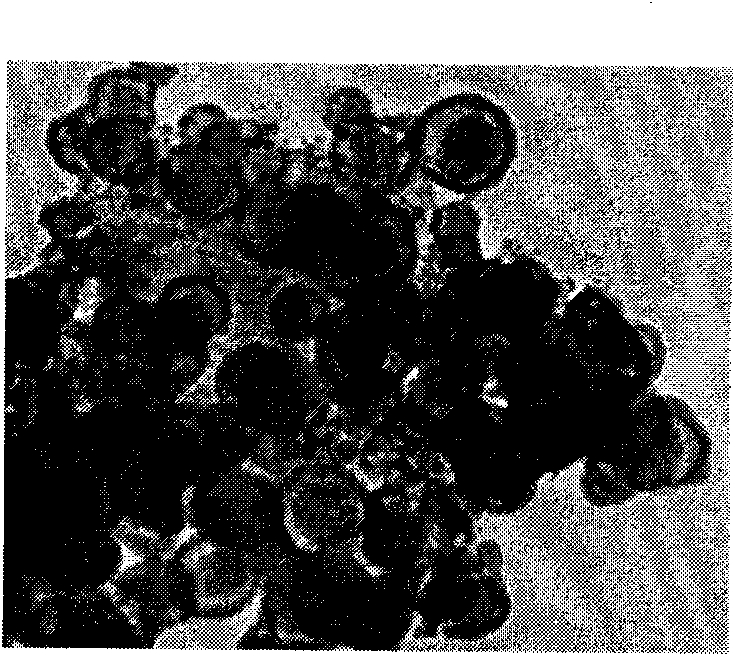

[0026] The chitosan-silicon dioxide composite hollow microspheres in the above system are observed by a transmission electron microscope as a relatively regular spherical structure with an average particle diameter of 110nm and can exist stably in a wide range of pH values.

Embodiment 3

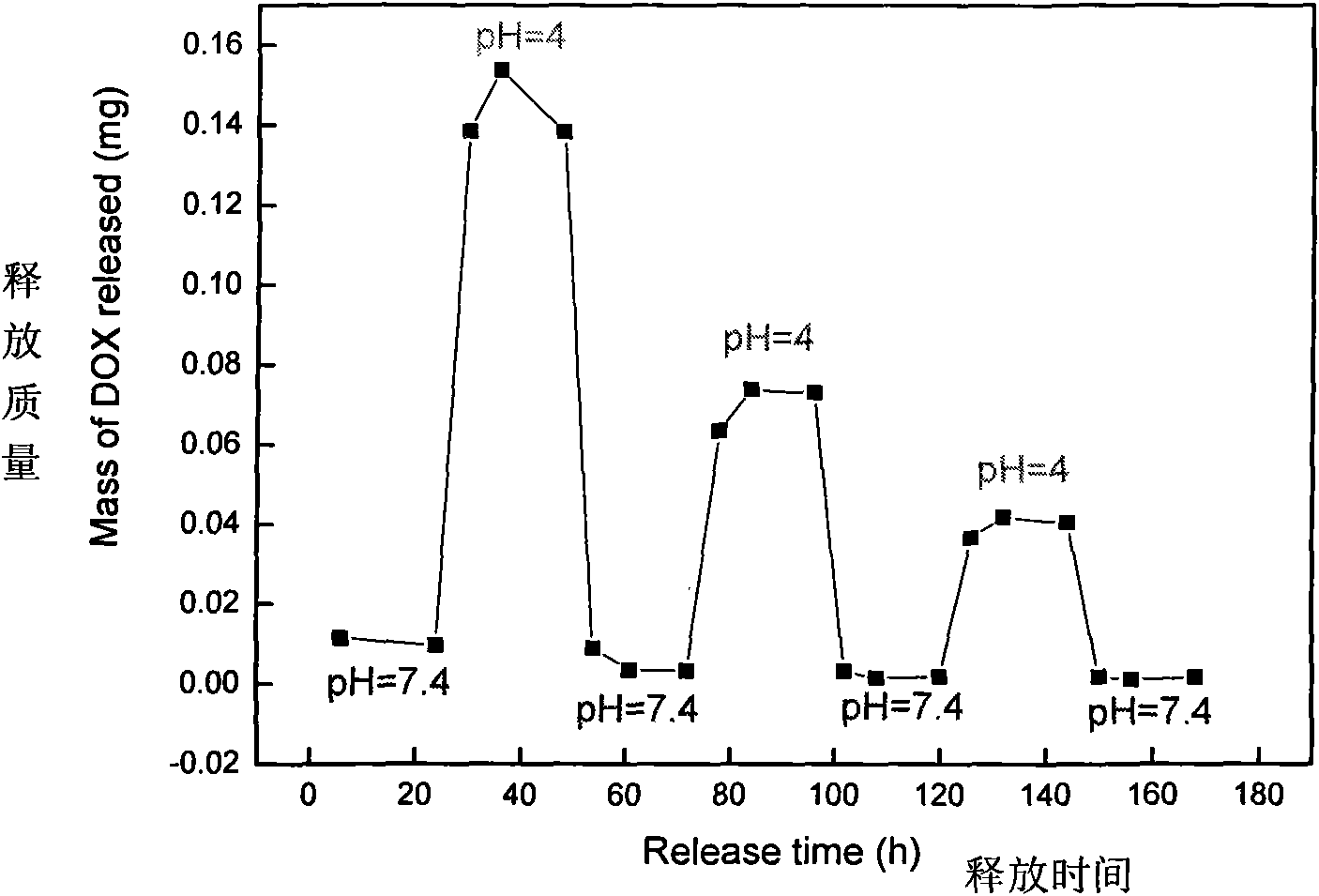

[0028] Take the newly prepared chitosan-polyacrylic acid emulsion 2.5mL and mix it with an equal volume of 2M ammonia water, and let it stand for 48 hours. Dissolve 520 microliters of ethyl orthosilicate in 2 mL of ethanol. The alkaline chitosan-polyacrylic acid emulsion was slowly added dropwise to the ethanol solution of tetraethylorthosilicate. Stir at room temperature for 24 hours, then place it at 50° C. for 24 hours, filter and centrifuge to obtain chitosan-silicon dioxide composite hollow microspheres. The product was washed several times, dispersed in distilled water, frozen, and then freeze-dried in a lyophilizer. Take 15 mg of freeze-dried chitosan-silicon dioxide composite hollow microsphere powder and a certain quality of doxorubicin hydrochloride and mix them in distilled water, stir at room temperature for 48 hours, centrifuge and wash three times, remove the upper liquid to obtain loaded doxorubicin hydrochloride chitosan-silica composite microspheres.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com