Silicate positive electrode material for lithium ion power battery, preparation method thereof and lithium ion power battery

A technology for power batteries and positive electrode materials, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of complex liquid phase synthesis process, uneven mixing, difficult positive electrode materials, etc., and achieve good battery processing performance and high Safety performance, the effect of high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of lithium ion power battery silicate cathode material of the present invention comprises the following steps:

[0026] 1. Lithium in the lithium source compound: transition metal element: silicon in the silicon source compound is mixed in a molar ratio of 1.9 to 2.1:1:1, and carbon or carbon source compound is added at the same time, and silicon element and carbon or carbon source compound are decomposed to form The carbon molar ratio 1: greater than 0 to 2 forms a raw material mixture.

[0027] The lithium source compound is lithium hydroxide, lithium carbonate, lithium acetate, lithium chloride, lithium sulfate, lithium nitrate, lithium iodide, lithium tert-butoxide, lithium benzoate, lithium formate, lithium fluoride, lithium chromate, Lithium citrate tetrahydrate, lithium tetrachloroaluminate, lithium bromide, lithium tetrafluoroborate, lithium oxalate, or a mixture of two or more in any molar ratio.

[0028] The transition metal element ado...

Embodiment 1

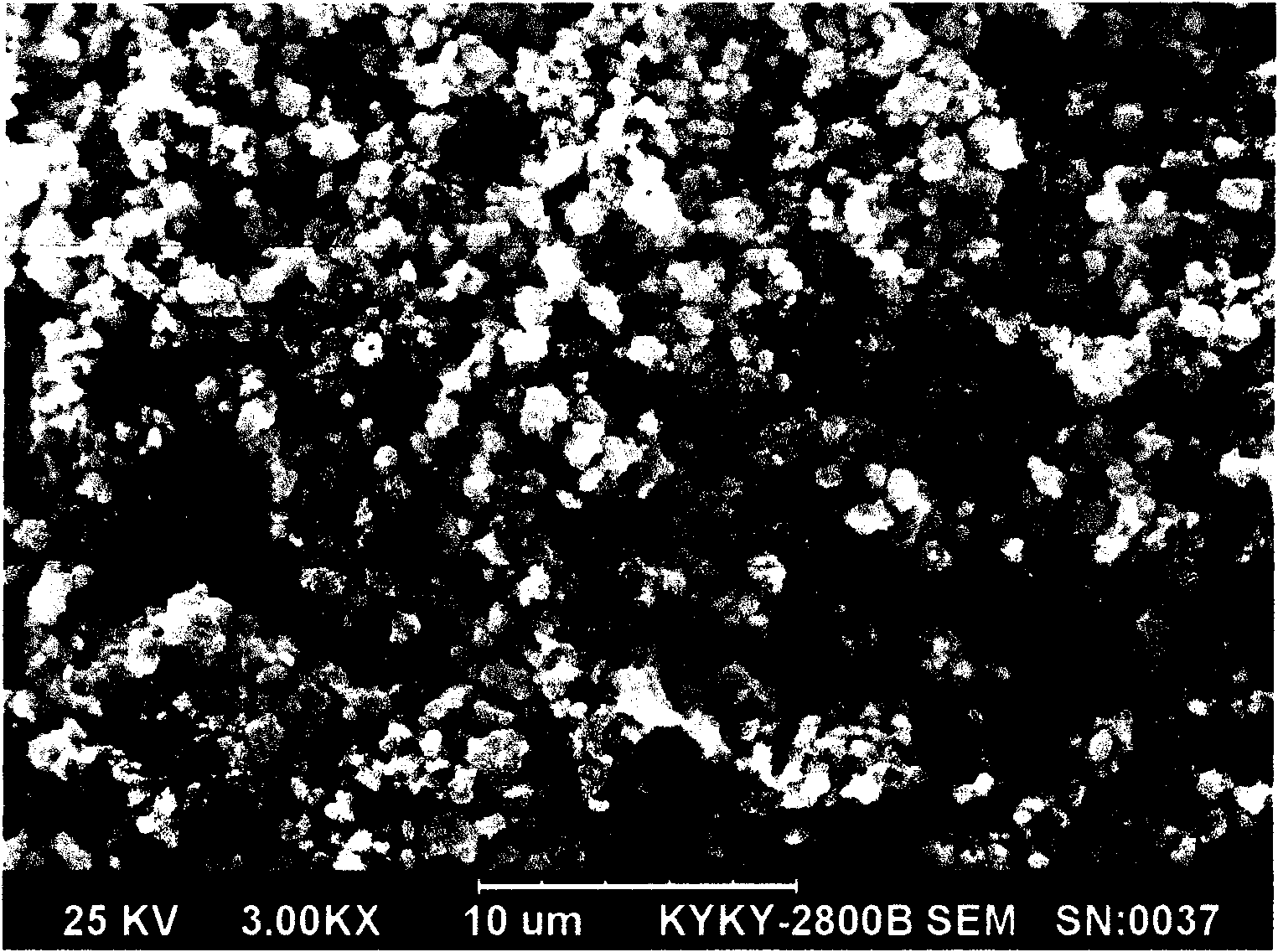

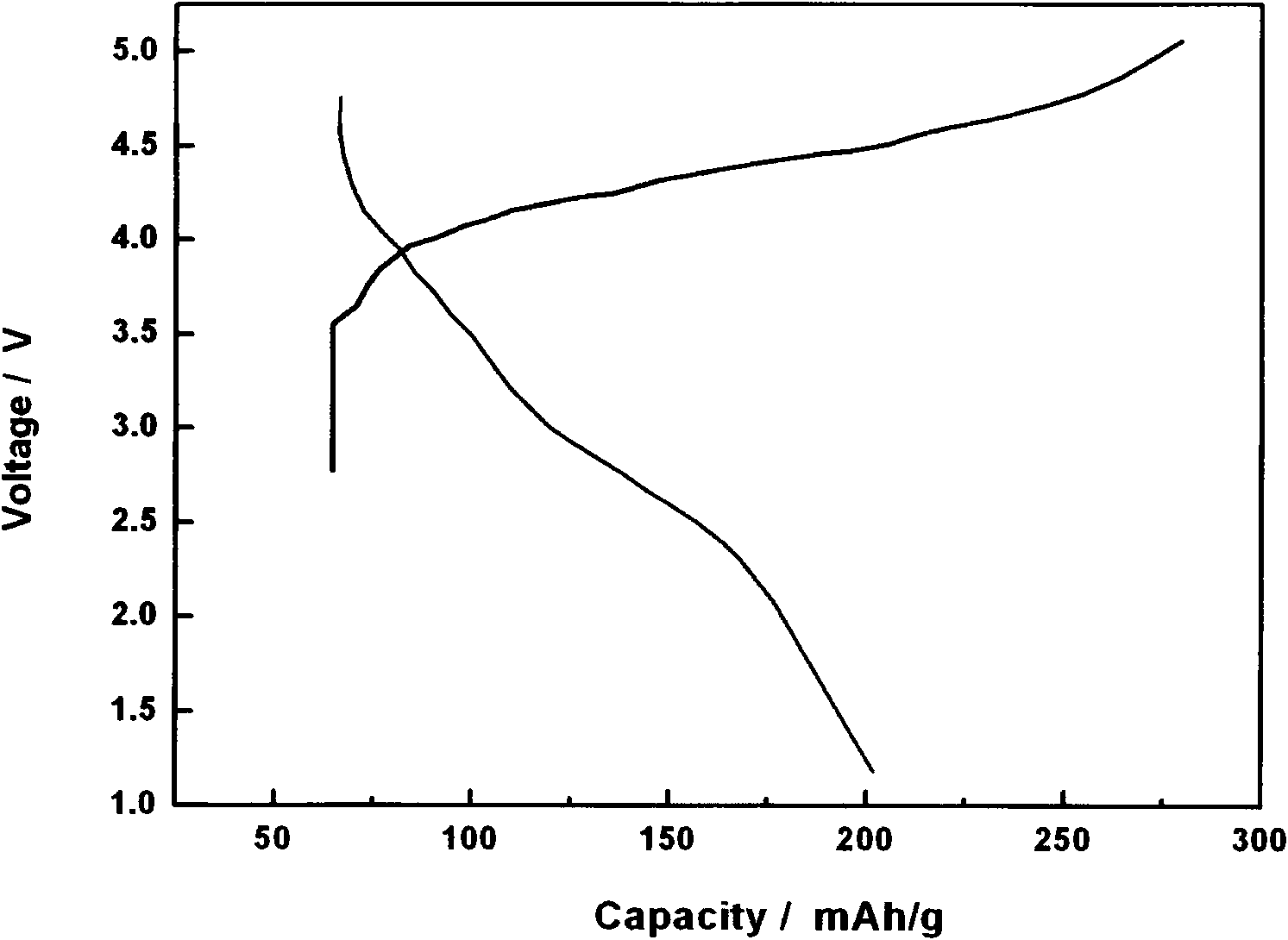

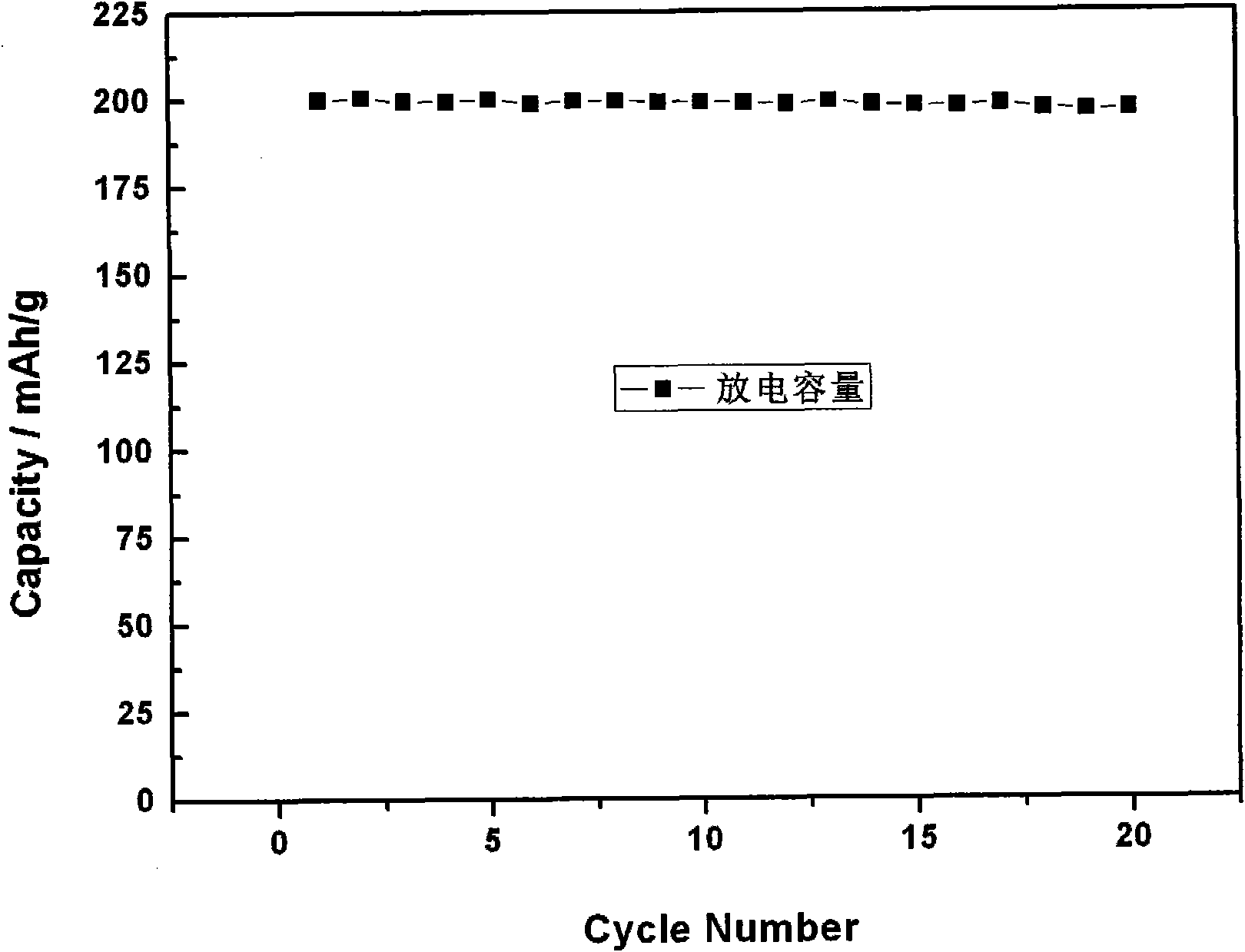

[0040] Example 1: Lithium in lithium hydroxide: manganese element in manganese nitrate: silicon in tetraethylorthosilicate 2: 1: 1 is mixed in molar ratio, add glucose simultaneously, the carbon mole that silicon element and glucose decompose generate The ratio is 1:1 to form a raw material mixture. Disperse the raw material mixture in water, the mass ratio of solid to water is 1:1, and then perform nano-processing in a nano-material preparation device, with a rotation speed of 100r / min, and grind and disperse for 40 hours to prepare the precursor of the silicate cathode material slurry. Put the precursor slurry into the storage tank and let it stand for 0.5h, then ultra-fine grinding, 1000r / min, time 2h, enter another storage tank and let it stand for 0.5h, then enter the dryer for drying treatment, and dry it in the gas phase at 100°C , to obtain a dispersed powder. The dispersed powder was heat-treated at a temperature increase rate of 1°C / min and within a temperature ran...

Embodiment 2

[0043] Example 2: Lithium in lithium carbonate: manganese element in manganese carbonate: silicon in silicon monoxide 1.9: 1: 1 is mixed in molar ratio, polyvinyl alcohol is added simultaneously, the carbon that silicon element and polyvinyl alcohol decompose generates The molar ratio is 1:2 to form a raw material mixture. Disperse the raw material mixture in ethanol, the mass ratio of solid to ethanol is 1.5:1, and then perform nano-processing in a nano-material preparation device at a speed of 500r / min, grind and disperse for 2 hours, and prepare the precursor of the silicate positive electrode material body slurry. Put the precursor slurry into the storage tank and let it stand for 1 hour, then ultra-finely grind it at 2000r / min for 1 hour, enter another storage tank and let it stand for 1 hour, then enter the dryer for drying treatment, and dry it in the gas phase at 200°C to obtain Disperse powder. The dispersed powder was heat-treated at a heating rate of 8°C / min and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com