Plant growth accelerant and preparation method thereof

A technology for promoting plant growth and discarding plants, which is applied to the field of plant growth promoters and their preparation, can solve the problems of separation and loss of effective components, low utilization rate of equipment, and many use of containers, and achieves considerable economic benefits, low cost and wide use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

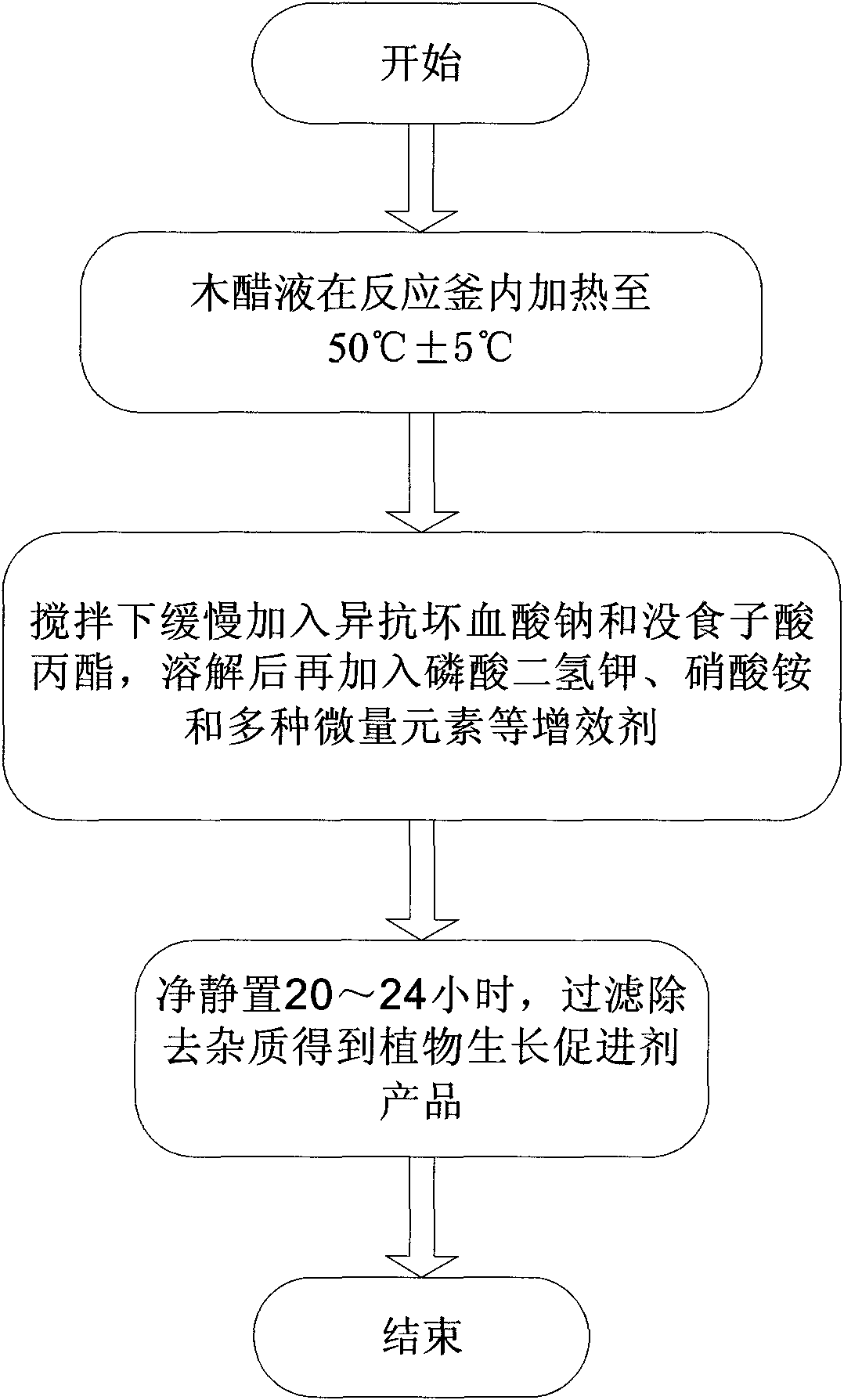

[0024] The present invention comprises the following steps for the preparation method of above-mentioned plant growth promoter:

[0025] Place the wood vinegar in a reaction kettle and heat it to 50±5°C;

[0026] Under the condition of stirring, slowly add an antioxidant comprising sodium erythorbate and propyl gallate into the reaction kettle, fully mix and dissolve;

[0027] Then add the synergist comprising potassium dihydrogen phosphate and ammonium nitrate in the reaction kettle, continue to stir, fully mix and dissolve;

[0028] allowing the resulting solution to stand for 20-24 hours; and

[0029] The resulting solution is filtered to remove impurities to obtain the plant growth promoter solution.

[0030] Among the added antioxidants, the added amount of sodium erythorbate is 0.05% to 0.1%, the added amount of propyl gallate is 0.025% to 0.05%, and the added amount of the added synergist is 0.1% ~0.5%.

[0031] Wherein, the added synergist also includes one or more...

Embodiment 1

[0035] Embodiment 1: the preparation of plant growth promoter

[0036] Put 400L of wood vinegar into a 500L reactor, heat up to 50°C and stop heating, slowly add 200g of sodium erythorbate under stirring, slowly add 150g of propyl gallate after dissolving, then add 40kg of potassium dihydrogen phosphate, ammonium nitrate 20kg, fully dissolved, left standstill for 20 hours, filtered with 200 mesh to remove impurities to obtain plant growth promoter solution.

Embodiment 2

[0037] Embodiment 2: the preparation of plant growth promoter

[0038] Put 400L of wood vinegar into a 500L reactor, heat up to 55°C and stop heating, slowly add 400g of sodium erythorbate under stirring, slowly add 200g of propyl gallate after dissolving, and then add 60kg of potassium dihydrogen phosphate, 30kg of ammonium nitrate, 5kg of borax, 4kg of magnesium sulfate, 2kg of copper sulfate, 2kg of zinc sulfate, 2kg of ferrous sulfate, 2kg of manganese sulfate, and 1kg of sodium molybdate are fully dissolved and mixed evenly. Saturated precipitation to obtain a plant growth promoter solution. The supersaturated precipitation refers to: the addition of synergists such as potassium dihydrogen phosphate, ammonium nitrate, borax, magnesium sulfate, copper sulfate, zinc sulfate, ferrous sulfate, manganese sulfate, and sodium molybdate may have an amount greater than that of the substance. Solubility, resulting in supersaturation and precipitation, so supersaturated precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com