Dental machinable diatomite full ceramic restoration material and preparation method thereof

A repair material, diatomite technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of low strength and affect the mechanical properties of materials, achieve good cutting performance, consistent strength and machinability, High toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

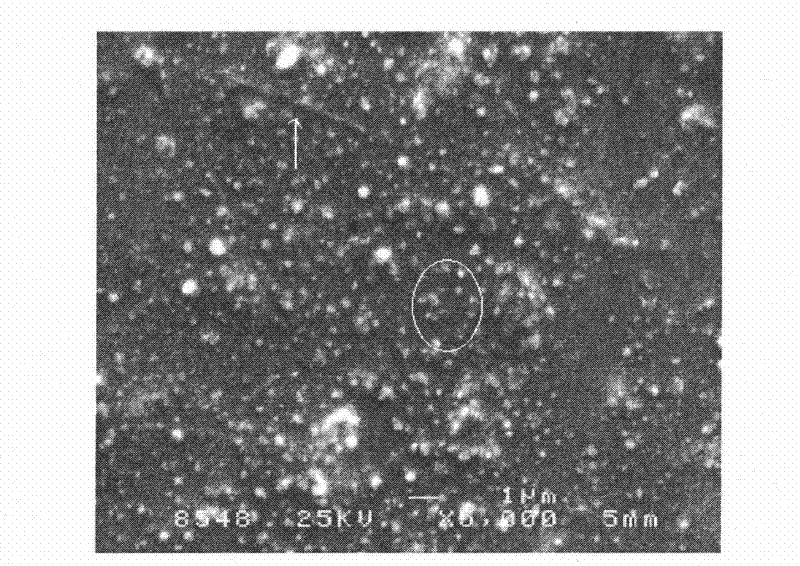

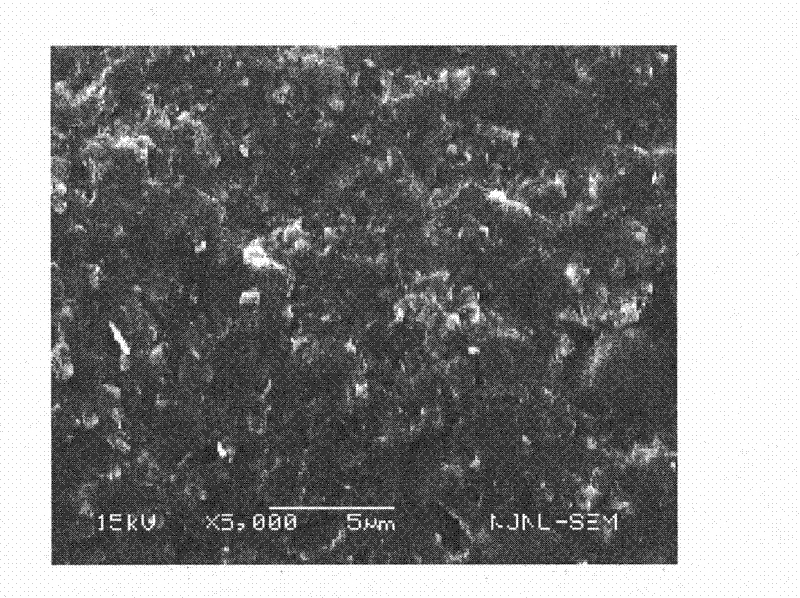

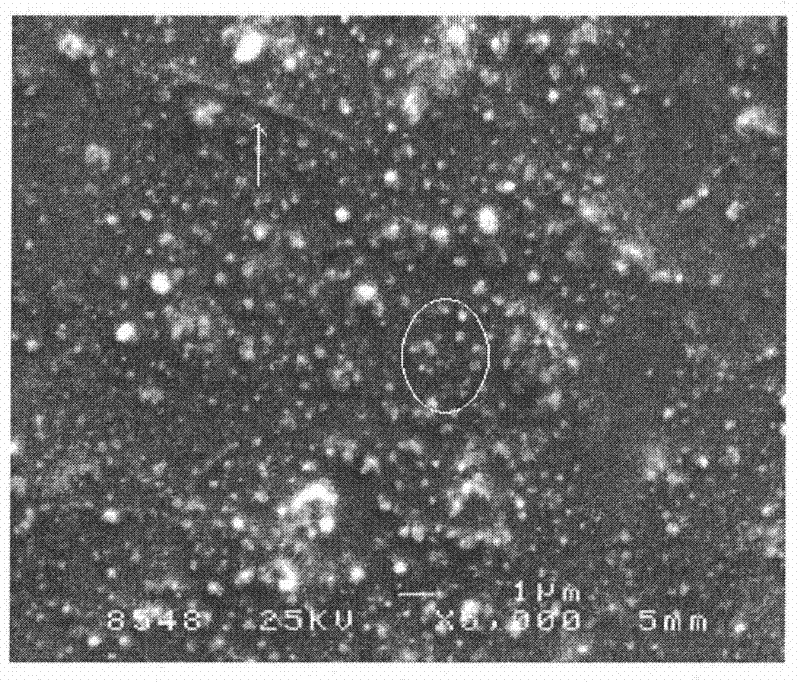

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of 1100°C dental machinable diatomite all-ceramic material

[0033] 1. Select raw material composition (mass%): diatomaceous earth 30%, bentonite 15%, quartz 5%, 3Y-ZrO 2 20%, α-Al 2 O 3 15% and TiO 2 Whiskers 10%, soda ash 5%.

[0034] 2. Put the prepared raw materials into the agate ball milling tank at the volume ratio of raw materials: agate balls: ethanol=1:1:1, and wet ball mill for 6-8 hours.

[0035] 3. After drying the ball-milled powder, it is manually ground and passed through a 100-mesh sieve.

[0036] 4. Mix the powder under the sieve with 5% polyvinyl alcohol (PVA) alcohol solution in a volume ratio of 1:1, and then dry it.

[0037] 5. The dried material is manually ground again, and passed through a 100-mesh sieve to obtain the powder of the diatomite all-ceramic restoration material.

[0038] 6. Weigh 0.8 grams of the above-mentioned powder, put it into an open-petal mold, and dry-press and shape it under a pressure of 500 MPa, hold the press...

Embodiment 2

[0041] Example 2: Preparation of a pre-sintered dental machinable diatomite all-ceramic material at 700°C

[0042] Select raw material composition (mass%): diatomite 35%, bentonite 15%, quartz 5%, 3Y-ZrO 2 15%, α-Al 2 O 3 10% and TiO 2 15% whisker, 5% soda ash.

[0043] The prepared raw materials are charged into an agate ball milling tank with a volume ratio of raw materials: agate balls: ethanol=1:1:1, and wet ball milling for 6-8 hours.

[0044] After the ball milled powder is dried, it is manually ground and passed through a 100 mesh sieve.

[0045] The powder under the sieve is mixed with 5% polyvinyl alcohol (PVA) alcohol solution in a volume ratio of 1:1, and then dried.

[0046] The dried material is manually ground again and passed through a 100-mesh sieve to obtain the powder of the diatomite all-ceramic restoration material.

[0047] Weigh 1.6 grams of the above-mentioned powder, put it into a cylindrical mold, and dry-press and shape it under a pressure of 700 MPa, hold the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com