Preparation of attapulgite modified by silane coupling agent

A silane coupling agent, soil silane coupling agent technology, applied in the field of high value-added attapulgite development and utilization, to achieve the effect of expanding the scope of use, expanding the use value and utilization rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

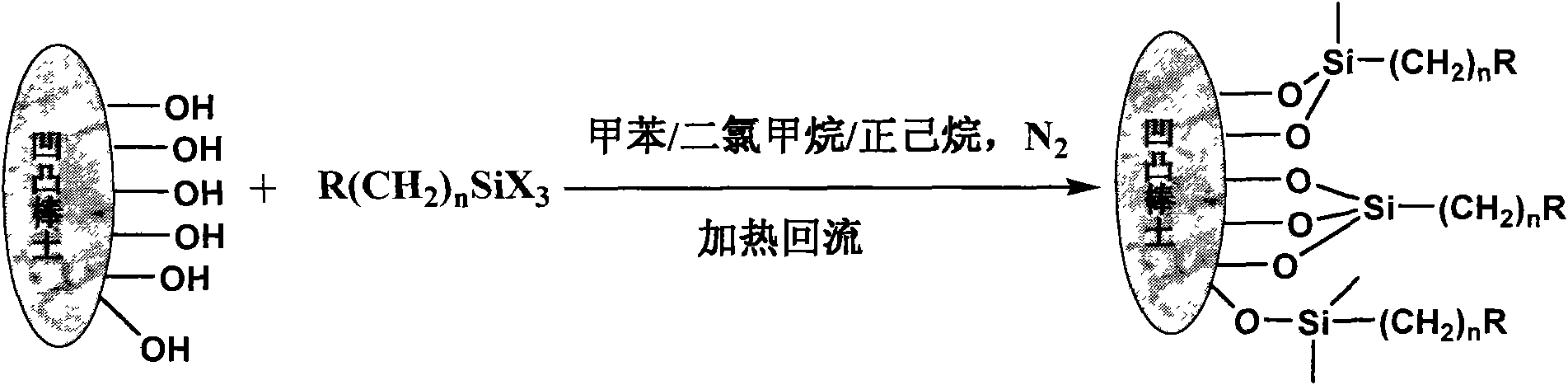

Method used

Image

Examples

Embodiment 1

[0022] The attapulgite used is the attapulgite raw ore collected from Xuyi, Jiangsu.

[0023] Acid treatment of attapulgite: Add 200mL of 2mol / L hydrochloric acid solution to 20g of attapulgite, shake in 60°C water at 120r / min for 120min, filter with suction, wash with deionized water until no chloride ion is detected with 0.1mol / L silver nitrate Afterwards, dry and crush through a 200-mesh sieve.

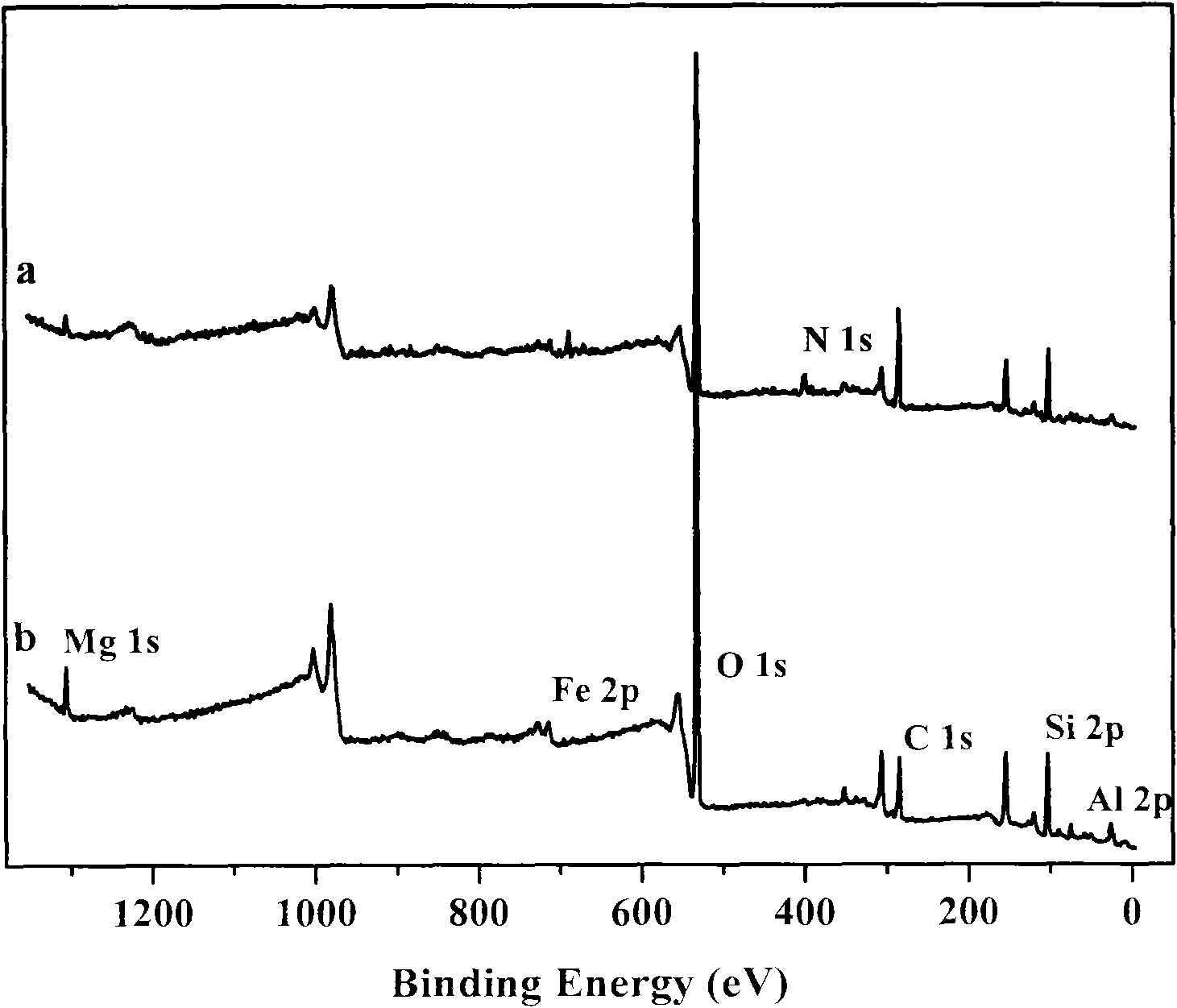

[0024] KH550 modified attapulgite: Weigh 10g of the above acid-treated attapulgite, add 500mL of dry toluene, stir to disperse the attapulgite evenly, then add 0.35g of coupling agent KH550, fill with nitrogen, heat and reflux for 10h, filter, and fully wash , remove the residual solvent, and pass through a 200-mesh sieve after drying to obtain the KH550 modified attapulgite product. attached by figure 2 It can be seen that the appearance of N element binding energy spectrum indicates that KH550 has condensed with attapulgite.

Embodiment 2

[0026] The attapulgite clay raw material used and the acid treatment of attapulgite are the same as in Example 1.

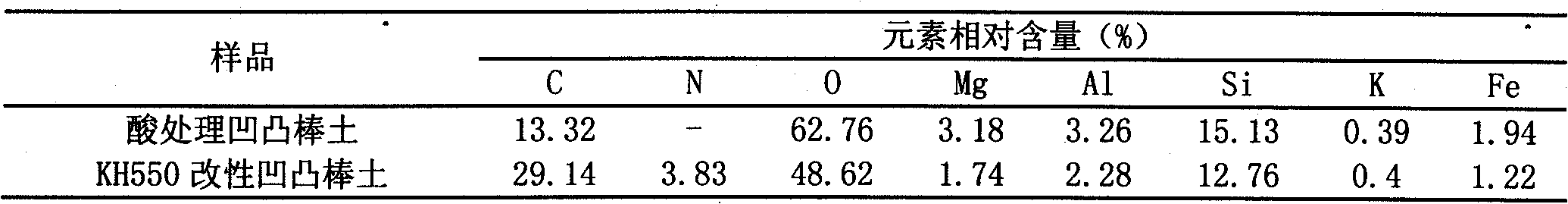

[0027] KH550 modified attapulgite: Weigh 0.2g coupling agent KH550, add 500mL dry dichloromethane, stir to disperse the attapulgite evenly, then add 10g of the above acid-treated attapulgite, heat and reflux for 30h, filter, wash, vacuum Remove the residual solvent, pass through a 200-mesh sieve after drying, and obtain the KH550 modified attapulgite product. The content changes of some elements in the product are shown in Table 1.

[0028] Table 1 XPS relative content changes of some elements before and after KH550 modification

[0029]

[0030] From the XPS relative content of some elements before and after modification in Table 1, it can be seen that the relative content of C and N elements increased to 29.14% and 3.83% respectively after modification.

Embodiment 3

[0032] The attapulgite clay raw material used and the acid treatment of attapulgite are the same as in Example 1.

[0033] KH550 modified attapulgite: Weigh 10g of acid-treated attapulgite, add 500mL of dry n-hexane, stir to disperse the attapulgite evenly, then add 0.6g of coupling agent KH550, fill with nitrogen, heat and reflux for 24h, filter, wash, Vacuum remove the residual solvent, pass through a 200-mesh sieve after fully drying, and obtain the KH550 modified attapulgite product. CHN elemental analysis was carried out on the product: the N content was 1.912%, and the C content was 6.005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com