Method for improving granulation performance of urine-based fertilizer

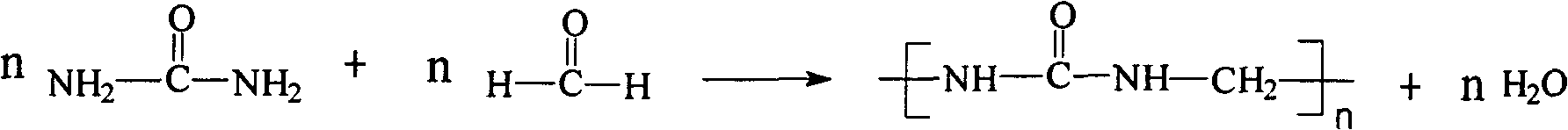

A technology of granulation and performance, applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer form, etc., can solve the problems of not easy to bond and granulate, difficulty in process granulation, decrease of equipment capacity, etc., to increase the slow-release effect and reduce the return rate. The amount of material and the effect of improving the production capacity of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

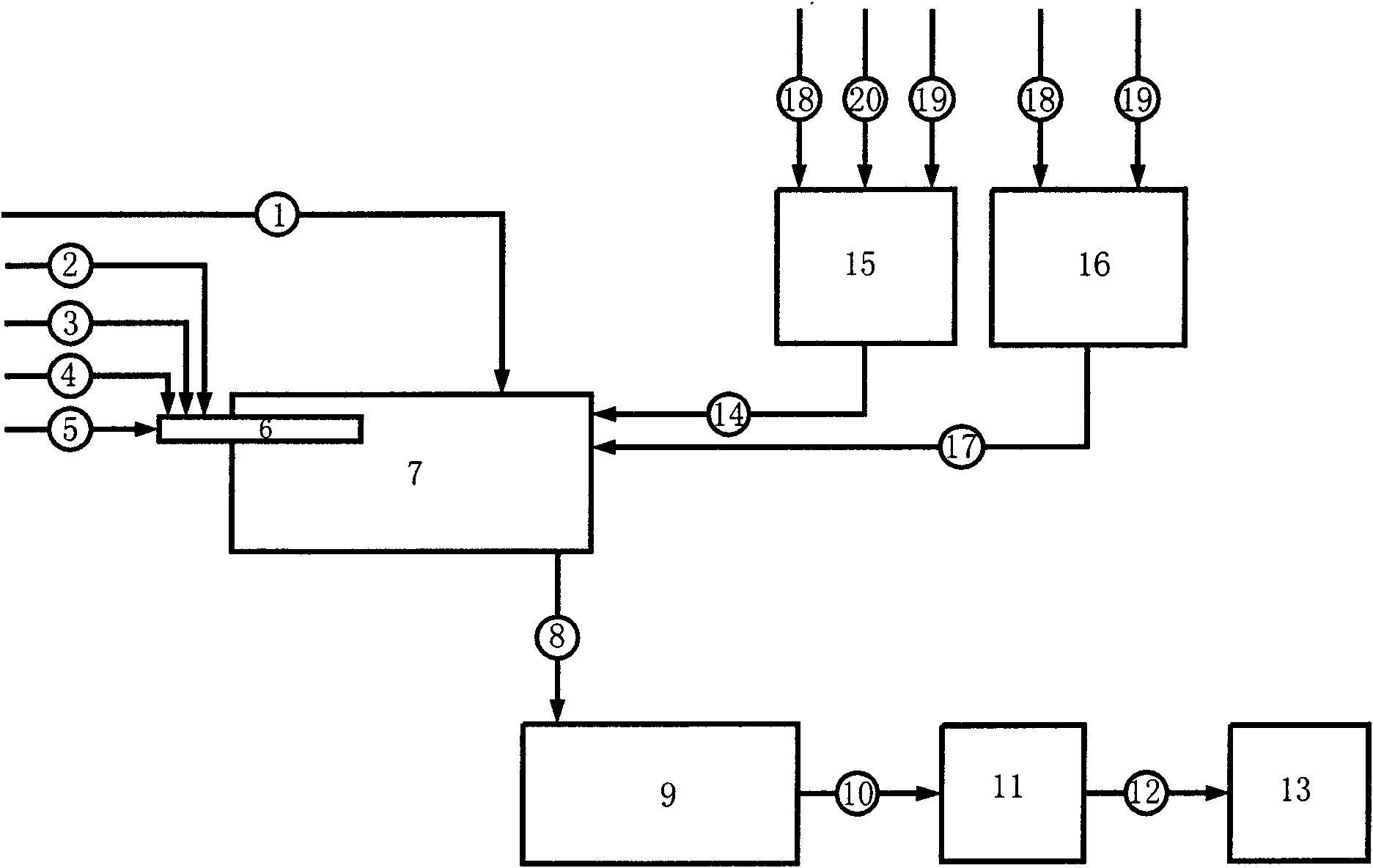

[0034] Taking 24-05-10 urine base fertilizer as an example, the design capacity of the device is 40t / h. The original feed rate is 3.5t / h for liquid ammonia 5, 2.9t / h for phosphoric acid 2, 10.0t / h for sulfuric acid 3, 45.7t / h for washing liquid into tubular reactor 6, and 7.5t for urea melt 14. / h is directly passed into the granulator 7, mixed with the material 1 of the granulation circuit in the granulator 7, and bonded into granules.

[0035]Take sodium carboxymethyl cellulose as binding agent, prepare the binding agent solution containing 2% sodium carboxymethyl cellulose, 1% zinc stearate and 5% sodium starch glycolate in the binding agent dissolving tank 16 17. Add granulator 7 at a speed of 8.0t / h, liquid ammonia 5 at 6.2t / h, phosphoric acid 2 at 5.1t / h, sulfuric acid 3 at 17.0t / h, washing liquid at 34.7t / h, urea melt at 14 The feeding amount is 5.5t / h, the device production capacity is increased to 70t / h, and the production capacity is 75% higher than the design value...

Embodiment 2

[0037] Same as in Example 1, prepare a binder solution 17 containing 8% borated dextrin, 1% casein and 3% modified starch in the binder dissolving tank 16, and feed it into the granulator 7 at a speed of 10.5t / h , 6.2t / h of liquid ammonia 5, 5.5t / h of phosphoric acid 2, 17.0t / h of sulfuric acid 3, 40.5t / h of washing liquid, 5.5t / h of urea melt 14, and the production capacity of the device increased to 70t / h, the production capacity is 75% higher than the design value. The nutrient content of the obtained finished fertilizer is N%: 24.3%, P 2 o 5 %: 6.0%, K 2 O%: 10.3%.

Embodiment 3

[0039] Taking 25-05-20 urine base fertilizer as an example, the production capacity of the plant without binder is 50t / h. The original feeding amount is liquid ammonia 5 to 0.6t / h, containing 50%P 2 o 5 Concentrated phosphoric acid 2 is passed into tubular reactor 6 at 5.0t / h, washing liquid at 25.5t / h, and urea melt 14 is directly passed into granulator 7 at 13.5t / h, and the material 1 in the granulation circuit is granulated Mix in the machine 7 and bond into granules.

[0040] Take sodium carboxymethyl cellulose as binding agent, prepare the binding agent solution 17 that contains 1% sodium carboxymethyl cellulose in binding agent dissolving tank 16, this binding agent aqueous solution add-on is the fertilizer output of unit time About 21%, that is, feed into granulator 7 at a speed of 15.0t / h, liquid ammonia 5 at 0.6t / h, containing 50%P 2 o 5 Concentrated phosphoric acid 2 is 5.0t / h, washing liquid is 18.5t / h, urea melt 14 is fed at 6.5t / h, and the production capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com