Preparation technology of children cold relaxation grain

Xiaoer Ganmaoshu Granules and preparation technology, which is applied in the field of preparation technology of Xiaoer Ganmaoshu Granules, can solve the problems of catmint oil with strong irritating smell, unsuitability for industrialized large-scale production, and large variable yield of volatile oil, etc., and achieve product quality Stable and controllable, shortened production cycle, and improved quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132]Recipe: Pueraria 400g, Nepeta 300g, Campanulaceae 250g, Scrophulariae 150g, Licorice 100g, Cicada slough 200g, Jianqu 300g, Arctium 300g.

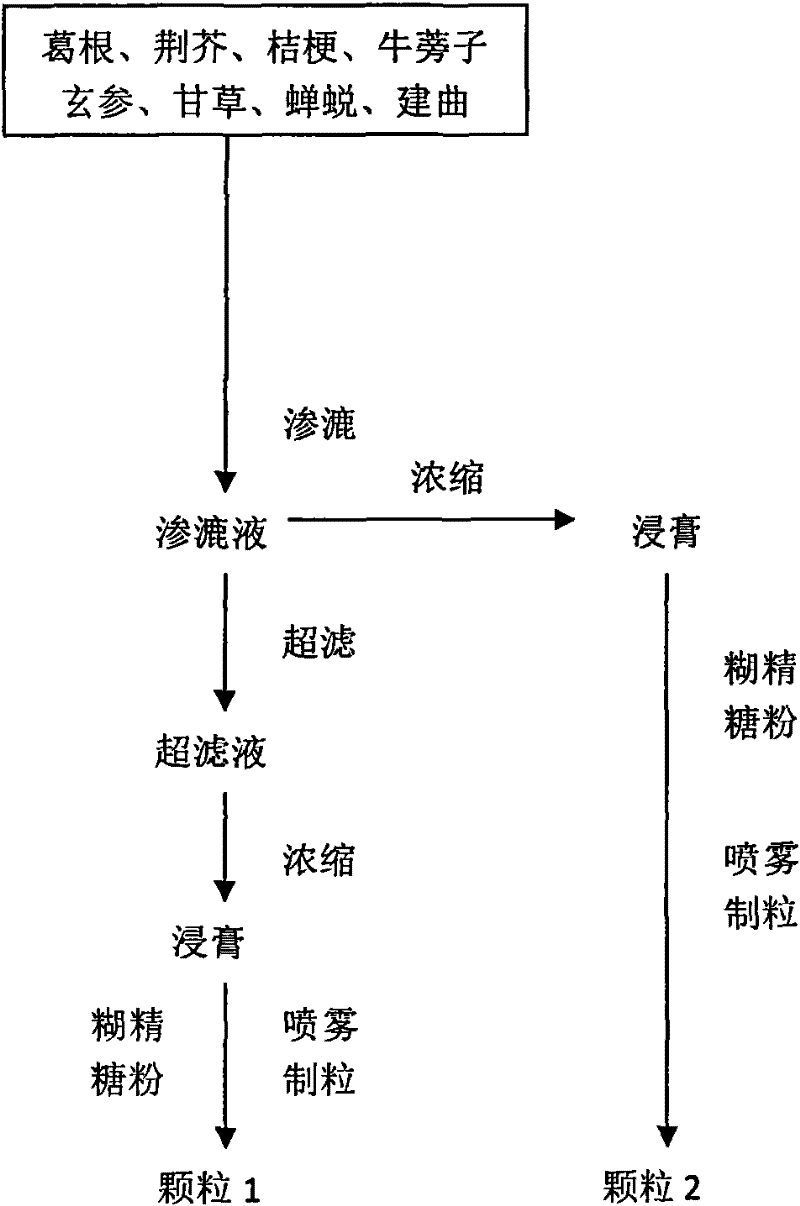

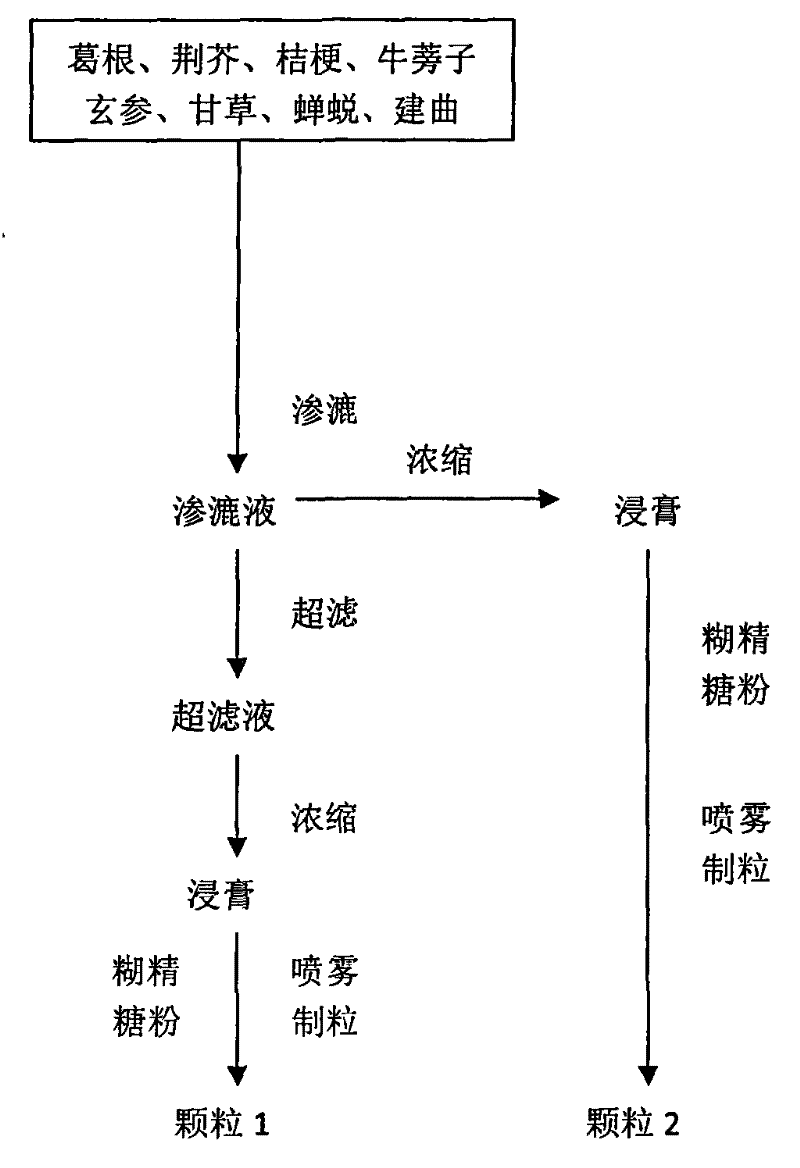

[0133] Preparation Process:

[0134] Mix kudzu root, nepeta, platycodon, scrophulariaceae, licorice, cicada slough, Jianqu and arctium evenly, grind them into coarse powder, add 1 times the total weight of medicinal materials in ethanol with a mass percentage concentration of 70%, soak for 6 hours, and then wash with The percolation rate per kilogram of medicinal material 6mL / min percolates, collects the percolation liquid of 5 times of the weight of the percolation medicinal material, and dries the leachate into an extract; mix fine powder of sucrose and dextrin (dextrin by weight: sucrose =1:4) mixed as a spray granulation carrier, the extract was spray granulated; when the primary air inlet temperature was 110°C, the material temperature was 55~65°C, and the speed of the peristaltic pump was 20rph, Xiaoermaoshu granules were obtai...

Embodiment 2

[0136] Recipe: Pueraria 300g, Nepeta 400g, Campanulaceae 300g, Scrophulariae 100g, Licorice 150g, Cicada slough 300g, Jianqu 400g, Arctium 400g.

[0137] Preparation Process:

[0138] Mix kudzu root, nepeta, platycodon, scrophulariaceae, licorice, cicada slough, Jianqu and arctium evenly, grind into coarse powder, add 1 times the total weight of medicinal materials to soak in 80% ethanol for 10 hours, and then add 14 mL / kg medicinal materials Min percolation speed percolation, collect the percolation liquid of 3 times of the total weight of the percolation medicinal materials, and dry the percolation liquid into extractum; mix fine powder of sucrose powder and dextrin (dextrin by weight: sucrose=1: 4) As a spray granulation carrier, the extract is sprayed and granulated, and dried to obtain it; when the primary air inlet temperature is 110°C, the material temperature is 55-65°C, and the speed of the peristaltic pump is 20rph, Xiaoermaoshu Granules are prepared .

Embodiment 3

[0140] Recipe: Pueraria 500g, Nepeta 200g, Campanulaceae 150g, Scrophulariaceae 200g, Licorice 50g, Cicada slough 150g, Jianqu 200g, Arctium 200g;

[0141] Preparation Process:

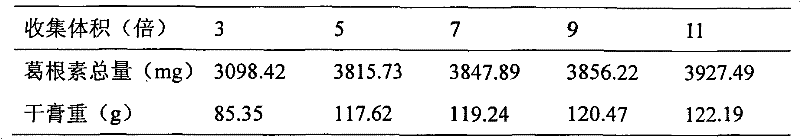

[0142] Mix kudzu root, nepeta, platycodon, scrophulariaceae, licorice, cicada slough, Jianqu and arctium evenly, pulverize into coarse powder, add 90% ethanol of 1 times the total weight of medicinal materials and soak for 8 hours, and then use 8mL / kg of medicinal materials Min percolation speed percolation, collect the percolation liquid which is 4 times the total weight of the percolation medicinal materials; take the percolation liquid and perform ultrafiltration at 25°C, the ultrafiltration membrane pore size is 50nm, and the membrane area is 0.2m 2 , in the ultrafiltration process, collect the ultrafiltrate of the percolation liquid amount of 1 times the total weight of the percolation medical material; then concentrate the ultrafiltrate into an extract with a relative density of 1.20 at 80 ° C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com