Alcohol preparation method by fermenting cane juice with foamed ceramic immobilized yeast

A technology for immobilizing yeast and foam ceramics, applied in biochemical equipment and methods, microorganism-based methods, immobilization on or in inorganic carriers, etc. The yeast activation time is long and the non-production cycle is prolonged to achieve the effect of improving equipment utilization, saving production time and not easy to contaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

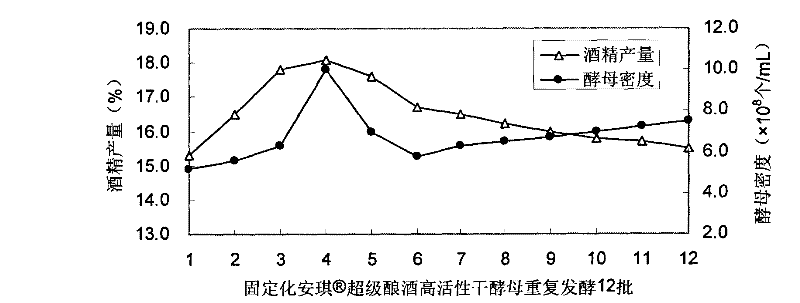

Embodiment 1

[0031] In the first step, in terms of weight percentage, the Angel Super Brewing high-activity dry yeast powder (sugar raw material) was added to the first sugarcane juice medium of 6°BX with pH 4.0 at 0.1%, and cultured at 20°C, 150rpm 12h, it becomes the yeast seed liquid; the raw material formula of the first sugarcane juice medium is: peptone 5.0kg, yeast extract 2.0kg, diammonium citrate 1.0kg, dipotassium hydrogen phosphate 1.0kg, sugarcane juice 700kg, production Drink 291kg of drinking water, adjust the pH to 4.0 with 1.0mol / L sulfuric acid solution; stir and dissolve evenly, sterilize it with a plate heat exchanger under 0.4bar steam, keep it at 110°C for 10s, and cool to 20°C for standby; Angel Super brewing high-activity dry yeast powder is produced by Angel Yeast Co., Ltd. It has the characteristics of acid tolerance (pH 2.5), ethanol tolerance (>18%v / v), sugar tolerance (60% glucose), strong reproduction ability, and rapid main fermentation. .

[0032] In the second...

Embodiment 2

[0039] In the first step, the Angel Super Brewing High Active Dry Yeast Powder (carbohydrate raw material, same as in Example 1) was added to the first sugarcane juice medium at 10°BX with pH 6.0 at 1.0% in weight percentage. Cultivate at 300 rpm for 6 hours to become seed liquid; the first sugarcane juice medium formula is: peptone 20kg, yeast extract 10kg, diammonium citrate 5kg, dipotassium hydrogen phosphate 5kg, sugarcane juice 700kg, production and drinking Water 260kg, adjust pH to 6.0 with 0.1mol / L sulfuric acid solution; stir and dissolve evenly, use plate heat exchanger to sterilize under 0.6bar steam, keep at 140℃ for 5s, and cool to 30℃ for standby;

[0040] In the second step, in terms of volume percentage, 10% of the yeast seed liquid was inserted into the 20°BX mother starter medium, and cultured at 35°C and 300rpm for 6 hours to become the mother starter yeast suspension; the mother fermentation The medium formula is: 20kg of peptone, 10kg of yeast extract, 5kg of...

Embodiment 3

[0046] In the first step, in terms of weight percentages, the Angel Super Brewing High Active Dry Yeast Powder (sugar raw material, same as in Example 1) was added at 0.5% into a 9°BX sugarcane juice medium with pH 5.0 at 25.0°C, Cultivate for 9 hours at 175rpm to become seed liquid; in parts by weight, the sugarcane juice medium formula is: peptone 12kg, yeast extract 6kg, diammonium citrate 3kg, dipotassium hydrogen phosphate 3kg, sugarcane squeezed juice 600kg, Produce 376kg of drinking water, adjust pH to 5.0 with 0.5mol / L sulfuric acid solution; stir and dissolve evenly, sterilize with plate heat exchanger under 0.5bar steam, keep at 125℃ for 7.0s, and cool to 25℃ for standby;

[0047] In the second step, in terms of volume percentage, insert the yeast seed liquid into the 15°BX mother starter medium at 6%, and incubate at 27.5°C and 175rpm for 9 hours to become the mother starter yeast suspension; in parts by weight In total, the mother starter culture medium formula is: pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com