Synthesis method for elemental mercury sorbent

A synthesis method and adsorbent technology, applied in the field of energy and the environment, can solve the problems of lack of mercury control methods and technologies, and achieve the effects of easy operation, simple synthesis, and no harm to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] The solvent is: deionized water

[0022] The modifier is: copper chloride

[0023] Copper chloride: attapulgite 1:3

[0025] Measure 10g of copper chloride in the reactor, add 750ml of deionized water into the reactor and stir until it is completely dissolved, slowly add 30g of attapulgite of 325 mesh under constant stirring, vigorously stir for 2 hours at room temperature, filter, and the filtered The solid was dried at 70° C. for 10 hours and ground to 200 mesh to obtain an elemental mercury adsorbent modified by copper chloride attapulgite. The mass content of copper chloride in the elemental mercury adsorbent was measured to be 7.9%.

[0026] The adsorbent of the present invention is applied to the removal of elemental mercury in the tail gas of the power plant as follows: spray the adsorbent powder into the electrostatic precipitator or the bag filter, adjust the injection amount of the adsorbent according to the content of mercury i...

example 2~6

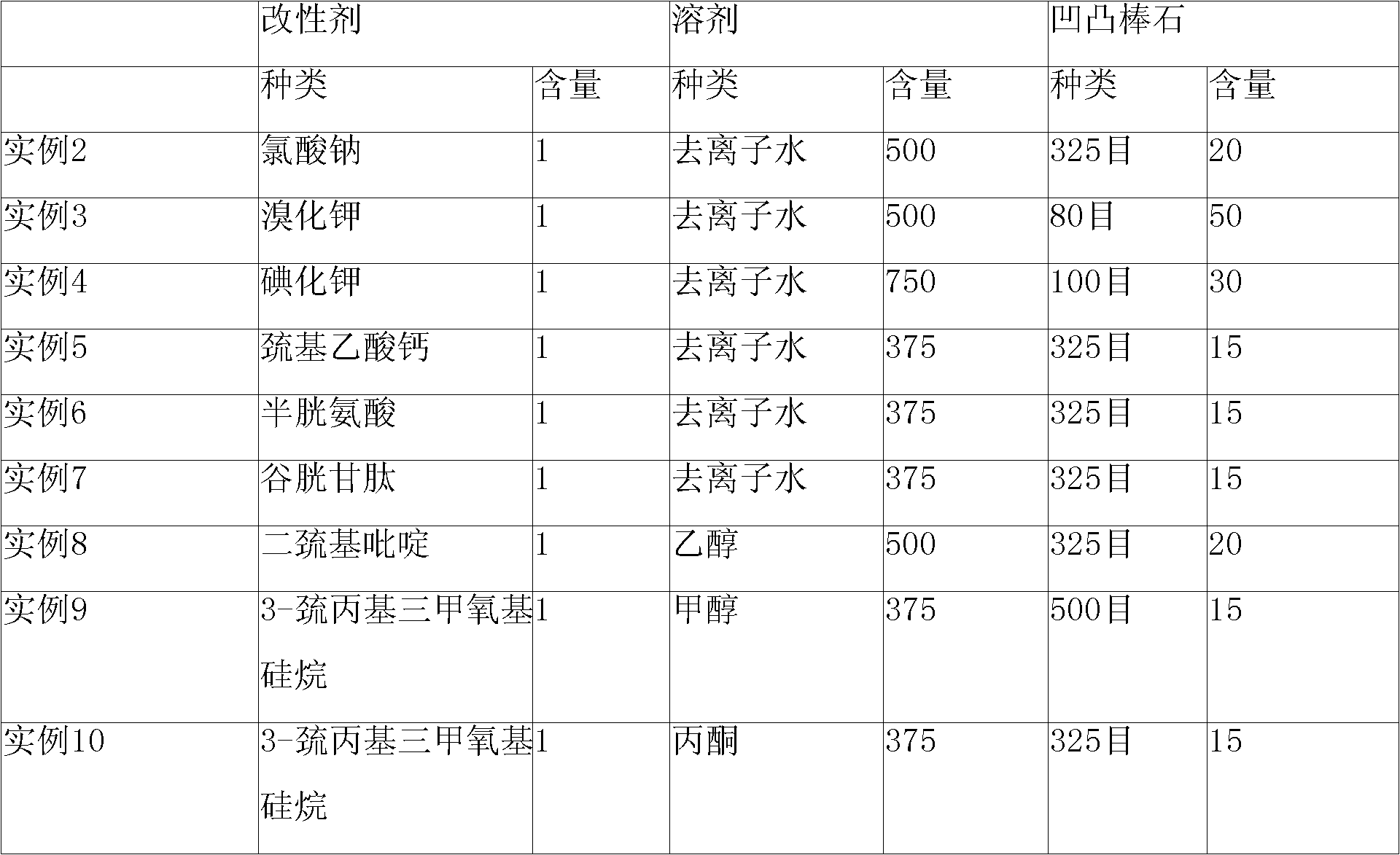

[0028] Examples 2-6 were prepared using the preparation method described in Example 1 according to the proportioning in the following table.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com