Method for treating industrial waste water

A treatment method and technology for industrial wastewater, applied in the direction of flocculation/sedimentation water/sewage treatment, combustion method, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of immature membrane separation technology and adsorption process, ion exchange method High cost, failure to achieve treatment effect and other problems, to achieve good wastewater treatment effect, high-efficiency flocculation effect, and little effect on pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

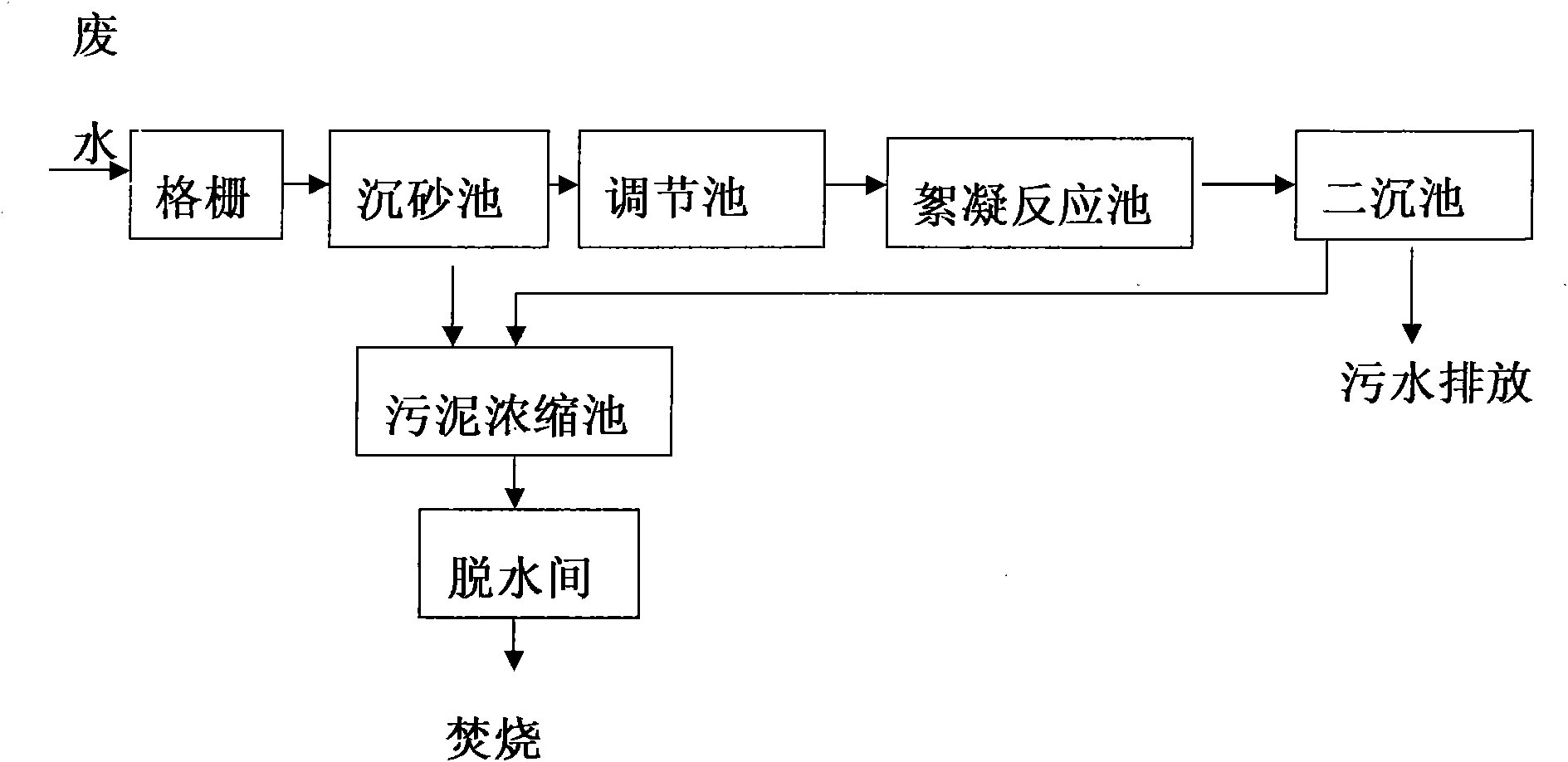

[0008] The present invention adopts the technique of combining physics and chemistry to process petroleum industry waste water, and the influent water quality is shown in Table 1, and its specific steps are:

[0009] (1) The waste water enters the grid first, the inclination angle of the grid is 60°, and the distance between the grid bars is 15 mm. When the waste water flows through, the large pollutants in a suspended state are intercepted by the grid bars and removed from the waste water;

[0010] (2) Effluent enters the grit chamber again to remove inorganic particles, and the waste water residence time is 3 hours;

[0011] (3) The effluent enters the regulating tank to keep the water quality and water quantity relatively stable to ensure the stable operation of the follow-up treatment system, and the residence time is 2 hours;

[0012] (4) The effluent enters the coagulation reaction tank again, and the coagulant polyaluminum chloride (PAC) is added therein to purify the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com