Preparation method of ligustrazine phosphate powder injection

A technology of ligustrazine phosphate and ligustrazine powder is applied in the directions of medical preparations containing active ingredients, powder delivery, pharmaceutical formulations, etc. Simple, short production cycle, less degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

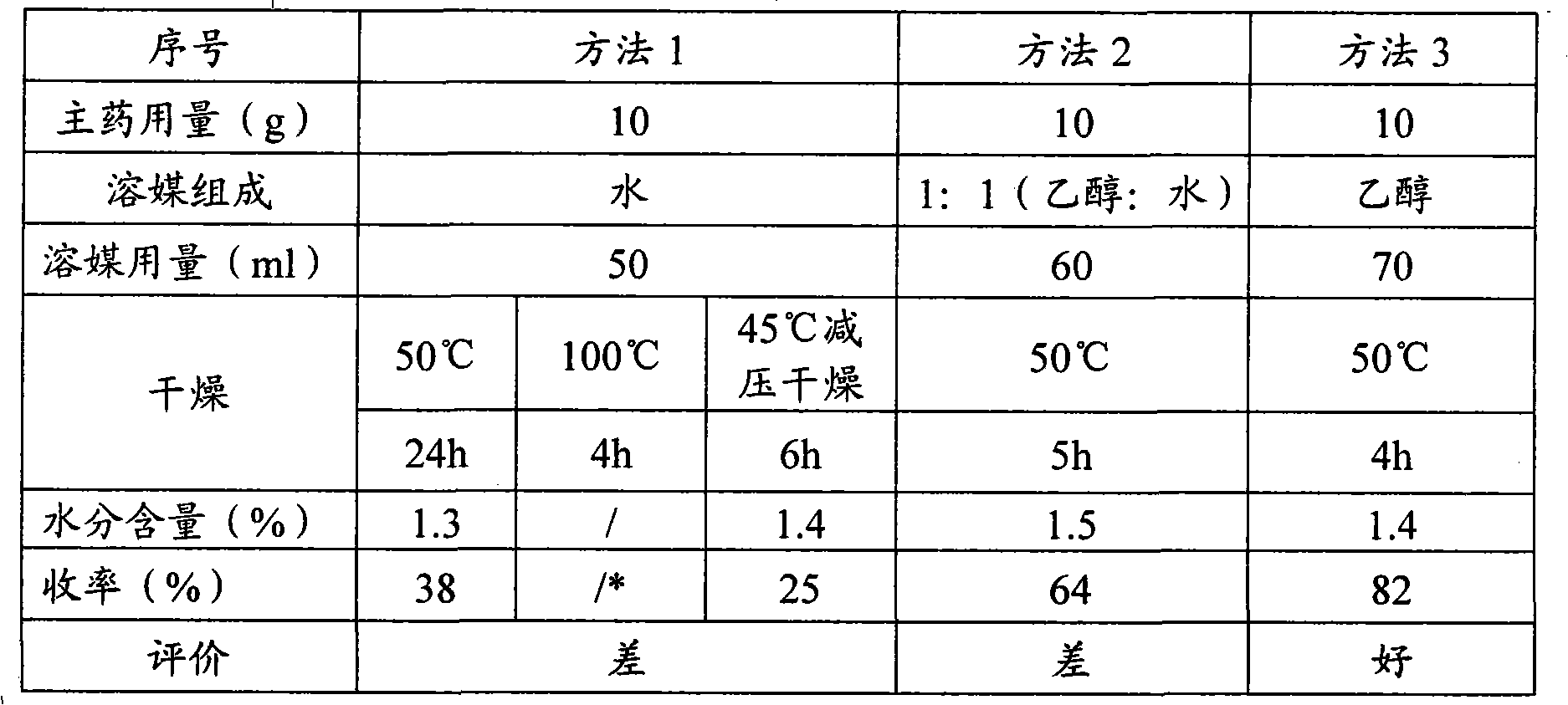

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 100g of ligustrazine phosphate in ethanol, heat in a water bath at 60°C to aid dissolution, and prepare 1000mL of ligustrazine phosphate ethanol solution, add 1g of medicinal charcoal to absorb for 20 minutes, filter and decarbonize to obtain the filtrate, and filter the filtrate with a pore size of φ0. 22μm microporous filter membrane, after sterilizing and filtering, crystallize at 0°C for 5 hours, crystallize while stirring at a stirring rate of 1200 rpm, and dry the precipitated crystals at 50°C for 4 hours after filtration to obtain 98 grams of injection Ligustrazine phosphate was used to subpackage, stopper, and cap according to the marked amount of 0.1 g / bottle to prepare 980 ligustrazine phosphate powder injections for injection.

Embodiment 2

[0032] Dissolve 100g of ligustrazine phosphate in ethanol, heat it in a water bath at 60°C to help dissolve it, and prepare 1000mL of ligustrazine phosphate ethanol solution, add 5g of medicinal charcoal to absorb for 50 minutes, filter and decarbonize to obtain the filtrate, and filter the filtrate with a pore size of φ0. After sterilizing and filtering with a microporous membrane of 8 μm, crystallize at 35°C for 12 hours, crystallize while stirring at a stirring rate of 60 rpm, and dry the precipitated crystals at 0°C for 12 hours after filtration to obtain 96.2 grams of injection Ligustrazine phosphate was used to subpackage, stopper, and cap according to the marked amount of 0.1 g / bottle to prepare 962 ligustrazine phosphate powder injections for injection.

Embodiment 3

[0034] Dissolve 100g of ligustrazine phosphate in ethanol, heat it in a water bath at 60°C to help dissolve, and prepare 1000mL of ligustrazine phosphate ethanol solution, add 30g of medical charcoal to absorb for 120 minutes, filter and decarbonize to obtain the filtrate, and filter the filtrate with a pore size of φ0. 45 μm microporous filter membrane, after sterilizing and filtering, crystallize at 20°C for 48 hours, crystallize while stirring at a stirring rate of 2000 rpm, and dry the precipitated crystals at 80°C for 8 hours after filtration to obtain 95.2 g injection Ligustrazine phosphate was used to subpackage, stopper, and cap according to the marked amount of 0.1 g / bottle to prepare 952 ligustrazine phosphate powder injections for injection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com