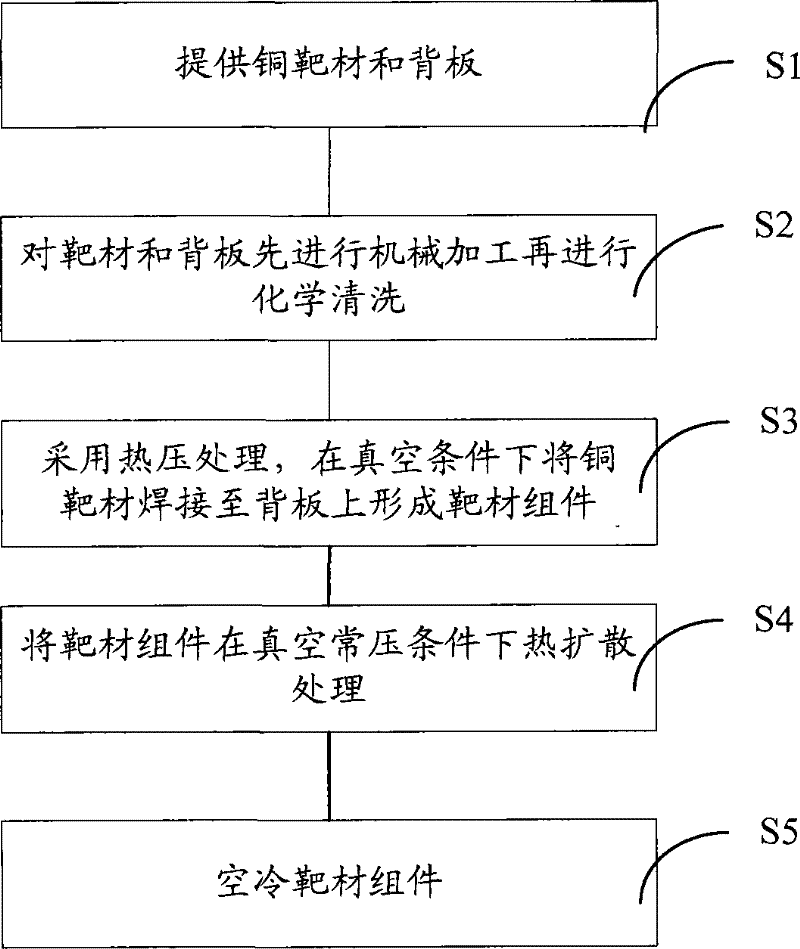

Welding method of target materials and back plates

A welding method and backplane technology, which are used in welding equipment, non-electric welding equipment, metal material coating processes, etc., can solve the problems of easy oxidation and affect the welding effect of target components, and achieve high bonding tightness and small bending deformation. , the effect of increasing the degree of mutual diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

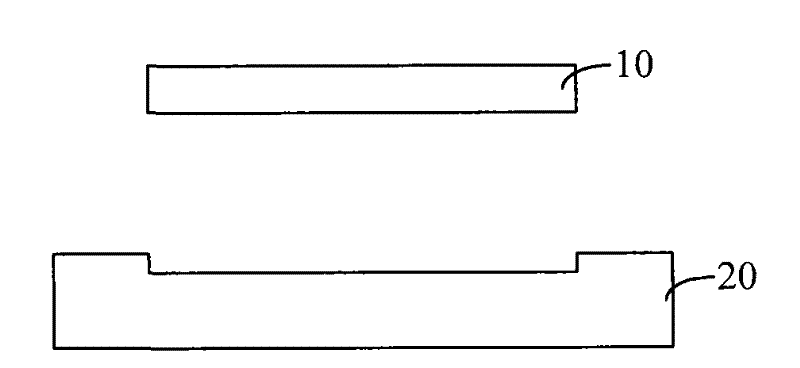

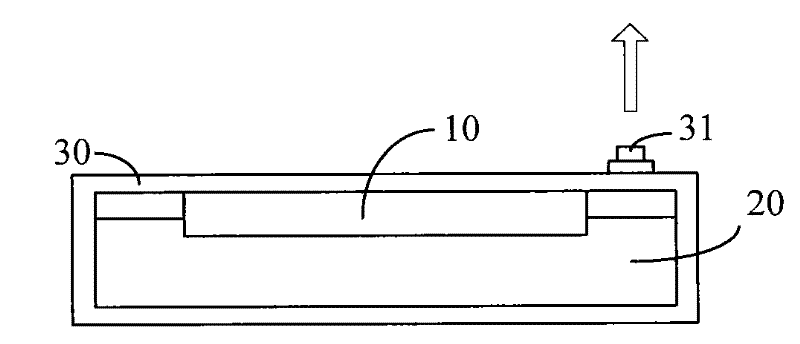

[0032] The process steps and welding results of diffusion welding between 99.9999% high-purity Cu target and 6061Al alloy backplane are as follows:

[0033] (1) Surface processing of the target and the back plate: machine the surface of the Cu target and the surface of the 6061Al alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 0.2um to 1.6um.

[0034] (2) Chemical cleaning of the target material and the back plate: the Cu target is first cleaned with an acid solution, and then cleaned with an organic solvent; and the 6061Al alloy back plate is directly cleaned with an organic solvent. The acid solution used for cleaning can be hydrofluoric acid (HF) and nitric acid (HNO 3 ), the mixed solvent of hydrofluoric acid (HF) and nitric acid (HNO 3 ) in the mixed solvent, the proportion of hydrofluoric acid is 3% to 15%, and the proportion of nitric acid can be 85% to 97%; as preferred, HF:HNO 3 The proportioning ratio is...

Embodiment 2

[0043] The following is another process step and welding result of diffusion welding between the 99.9999% high-purity Cu target and the ZL105 aluminum alloy backplane: (1) Surface processing of the target and backplane: the surface of the Cu target and the surface of the ZL105 aluminum alloy backplane Carry out mechanical processing to make it bright, especially to make the smoothness of the contact surface between the two reach 1.6um to 3.2um.

[0044] (2) Chemical cleaning of the target material and the back plate: the Cu target is first cleaned with an acid solution, and then cleaned with an organic solvent; and the ZL105 aluminum alloy back plate is directly cleaned with an organic solvent. The acid solution used for cleaning can be hydrofluoric acid (HF) and nitric acid (HNO 3 ), the mixed solvent of hydrofluoric acid (HF) and nitric acid (HNO 3 ) in the mixed solvent, the proportion of hydrofluoric acid is 3% to 15%, and the proportion of nitric acid can be 85% to 97%; ...

Embodiment 3

[0053] The following are the process steps and results of diffusion welding of 99.9999% high-purity Cu target and oxygen-free copper backplane:

[0054] (1) Surface processing of the target material and the back plate: machine the surface of the Cu target and the surface of the oxygen-free copper back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 0.2um to 3.2um.

[0055] (2) Chemical cleaning of the target material and the backplane: the Cu target is first cleaned with an acid solution, and then cleaned with an organic solvent; and the oxygen-free copper backplane is directly cleaned with an organic solvent. The acid solution used for cleaning can be hydrofluoric acid (HF) and nitric acid (HNO 3 ), the mixed solvent of hydrofluoric acid (HF) and nitric acid (HNO 3 ) in the mixed solvent, the proportion of hydrofluoric acid is 3% to 15%, and the proportion of nitric acid can be 85% to 97%; as preferred, HF:HNO 3 The proport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com