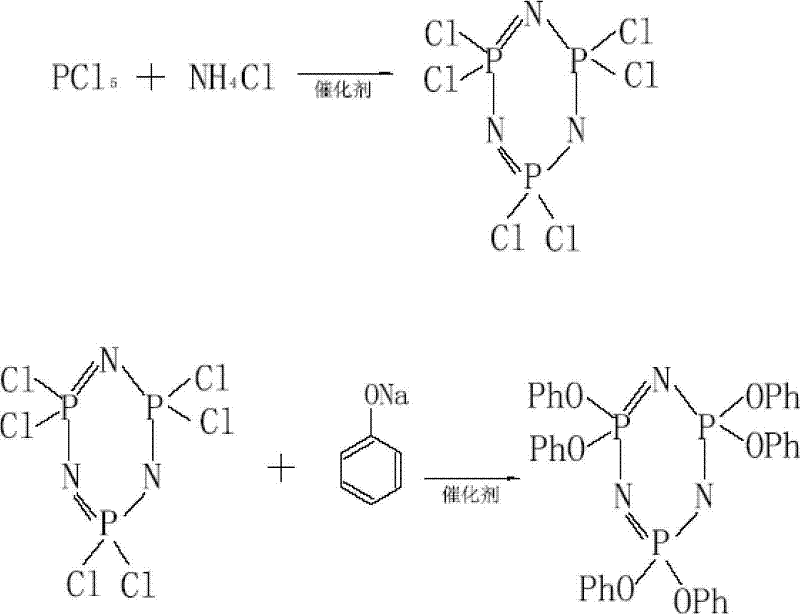

Preparation method of high purity hexaphenoxycyclotriphosphazene

A technology of hexaphenoxycyclotriphosphazene and hexachlorocyclotriphosphazene, which is applied in the field of synthesis of nitrogen-containing phosphorus organic compounds, can solve the problems of inconvenient industrial production, high volatility, and low boiling point, and reduce the pressure of purification , Increased reactivity, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 46 grams of ammonium chloride, 1.2 grams of magnesium chloride, and 250 grams of chlorobenzene into a three-necked flask equipped with a stirrer, condenser, and water separator tail gas absorption system, replace with nitrogen, and heat up to azeotropic dehydration at a temperature of 120-135°C. Finish, add dropwise at 125~135 ℃ the chlorobenzene solution that contains 150 grams of phosphorus pentachloride concentration and be 30%, the dropwise reaction time is 32 hours, after detecting that residual phosphorus pentachloride is qualified, reaction finishes, cools down, and filter out The reacted ammonium chloride is used in the next batch of reactions. The filtrate is washed twice with water at a washing temperature of 80°C. It is concentrated and steamed to remove most of the chlorobenzene, cooled and crystallized, filtered to obtain hexachlorocyclotriphosphazene, and recycled after filtering the mother liquor. The yield 80%, with a purity of over 99%; or the synthe...

Embodiment 2

[0040] Example 2: In Example 1, hexachlorocyclotriphosphazene was synthesized, adding 15 grams of catalyst pyridine, adding phosphorus pentachloride chlorobenzene solution dropwise, and reflux reaction for 16 hours, with a yield of 84% and a purity of 99%. In the synthesis of hexaphenoxycyclotriphosphazene, add 20 grams of PEG1000 catalyst, do not use alkali washing, acid washing, directly wash with methanol, the reaction is completed, the yield is 95%, the purity is 99%, and the chlorine content is less than 500ppm.

Embodiment 3

[0041] Embodiment 3: adopt the method of embodiment 1, hexachlorocyclotriphosphazene synthetic reaction finishes, reaction mixture is filtered, and mother liquor is washed with water, concentrates to obtain the chlorobenzene solution containing 25~30% of hexachlorocyclotriphosphazene. In the synthesis of hexaphenoxycyclotriphosphazene, a chlorobenzene solution containing 25% to 30% of hexachlorocyclotriphosphazene is used to react with sodium phenate, and the reaction ends with a yield of 80% and a purity of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com