Test method of micro amount of arsenic or antimony in steel

A detection method and technology for iron and steel, applied in the detection of antimony and trace arsenic in iron and steel, can solve the problems of limited element determination by instruments, harmful operators, expensive instruments, etc., and achieve simple operation, good stability, and little matrix interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] Weigh 0.1000g of a steel sample containing different amounts of arsenic and antimony into a 150mL conical flask, add 10mL of concentrated hydrochloric acid, 3mL of concentrated nitric acid, and 10mL of (1+1) sulfuric acid, heat to dissolve the sample (if insoluble A few drops of hydrofluoric acid can be added dropwise to help dissolve), heated to fume of sulfuric acid for 1-2min, removed and cooled slightly, and dissolved in water with salt (if there is carbide precipitation, filter it out) add 10mL100g·L -1 Tartaric acid solution, 10mL100g·L -1 Citric acid solution, add 200g·L -1 Thiourea-200g·L -1 Ascorbic acid mixed solution 10mL, take it out after slightly heating, transfer it into a 100mL volumetric flask after cooling, dilute to the mark with 5% hydrochloric acid solution, shake well for testing.

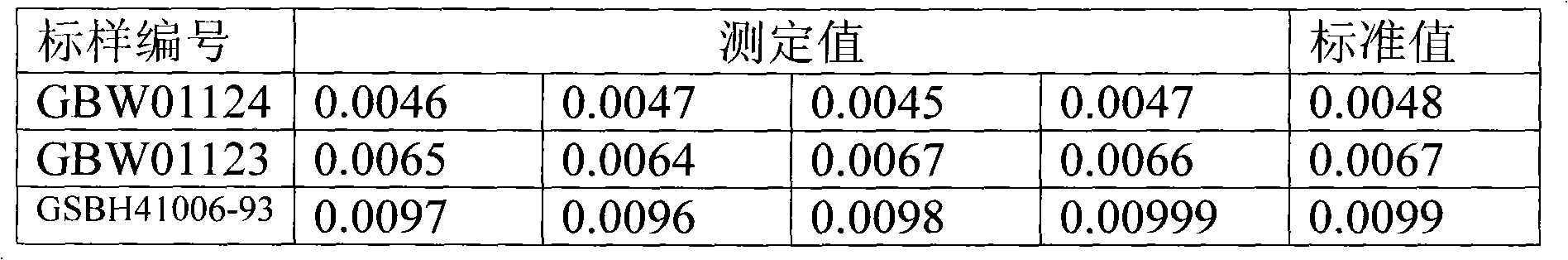

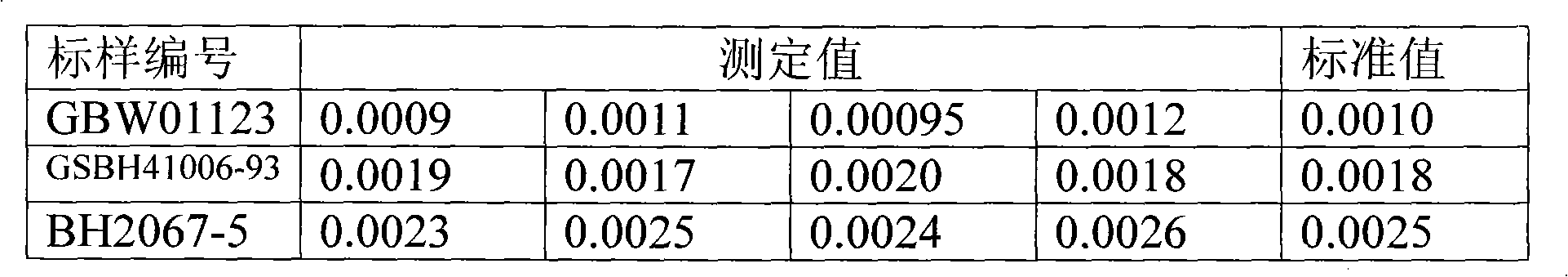

[0052] Under the working conditions selected by the instrument, the absorbance value of arsenic and antimony is measured, and the content of arsenic and antimony in t...

specific Embodiment 2

[0053] Operate a sample containing arsenic and antimony in the same manner as in Example 1, dilute it to the mark with 10% hydrochloric acid solution, and shake it up for testing.

[0054] Under the working conditions selected by the instrument, the absorbance value of arsenic and antimony is measured, and the content of arsenic and antimony in the sample is found out from the calibration curve drawn by steel standard samples containing different amounts of arsenic and antimony operated under the same conditions.

specific Embodiment 3

[0055] Operate a sample containing arsenic and antimony in the same manner as in Example 1, dilute it to the mark with 25% hydrochloric acid solution, shake it up to be tested.

[0056] Under the working conditions selected by the instrument, the absorbance value of arsenic and antimony is measured, and the content of arsenic and antimony in the sample is found out from the calibration curve drawn by steel standard samples containing different amounts of arsenic and antimony operated under the same conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com