Process for improving chemical reaction conversion rate by utilizing FAU-type molecular sieve membrane

A technology of chemical reaction and molecular sieve, applied in chemical/physical/physicochemical processes, organic chemistry, bulk chemical production, etc., can solve the problems of complex operation, low efficiency, high energy consumption, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Separation performance of microwave-synthesized FAU type molecular sieve membrane

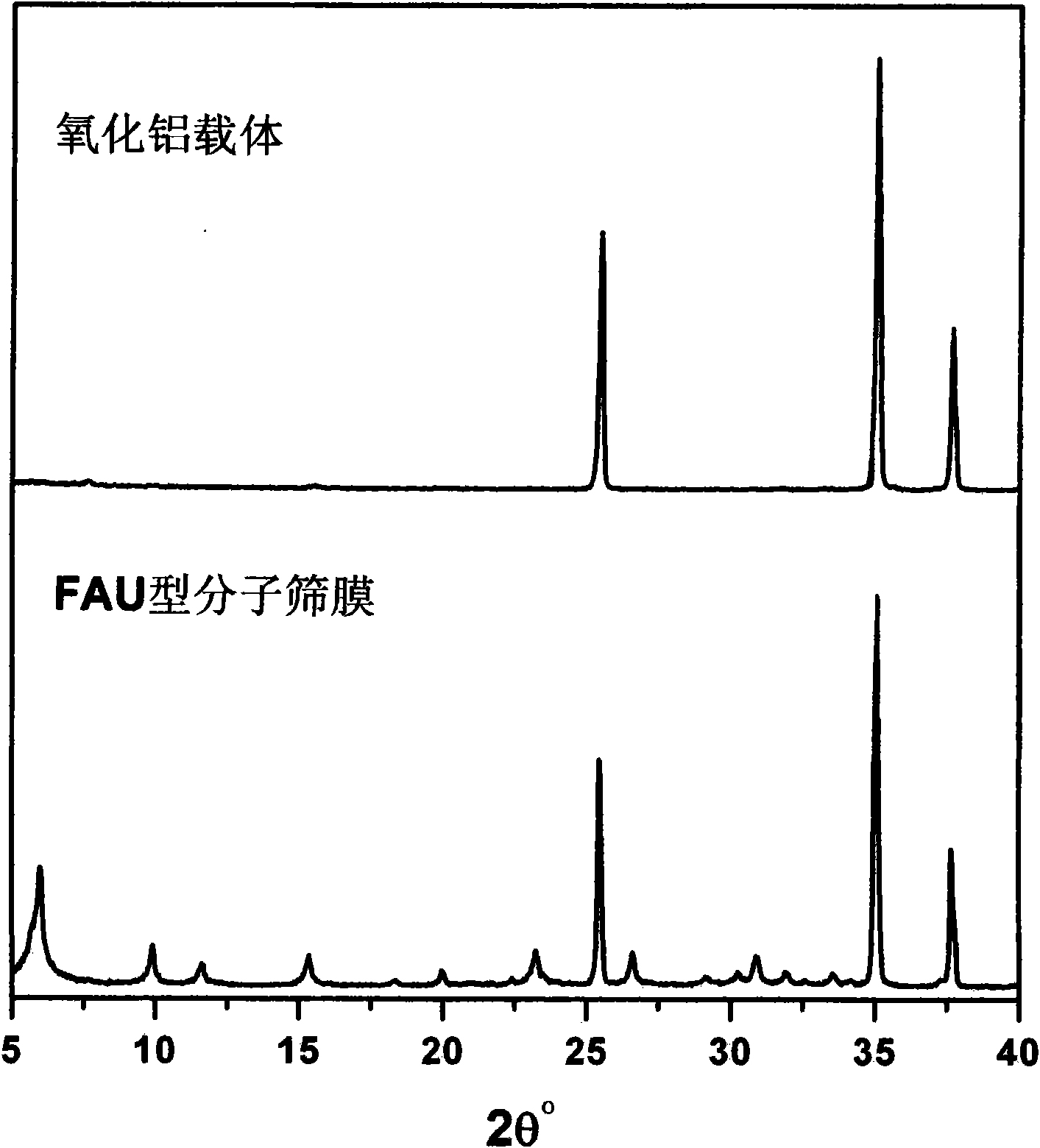

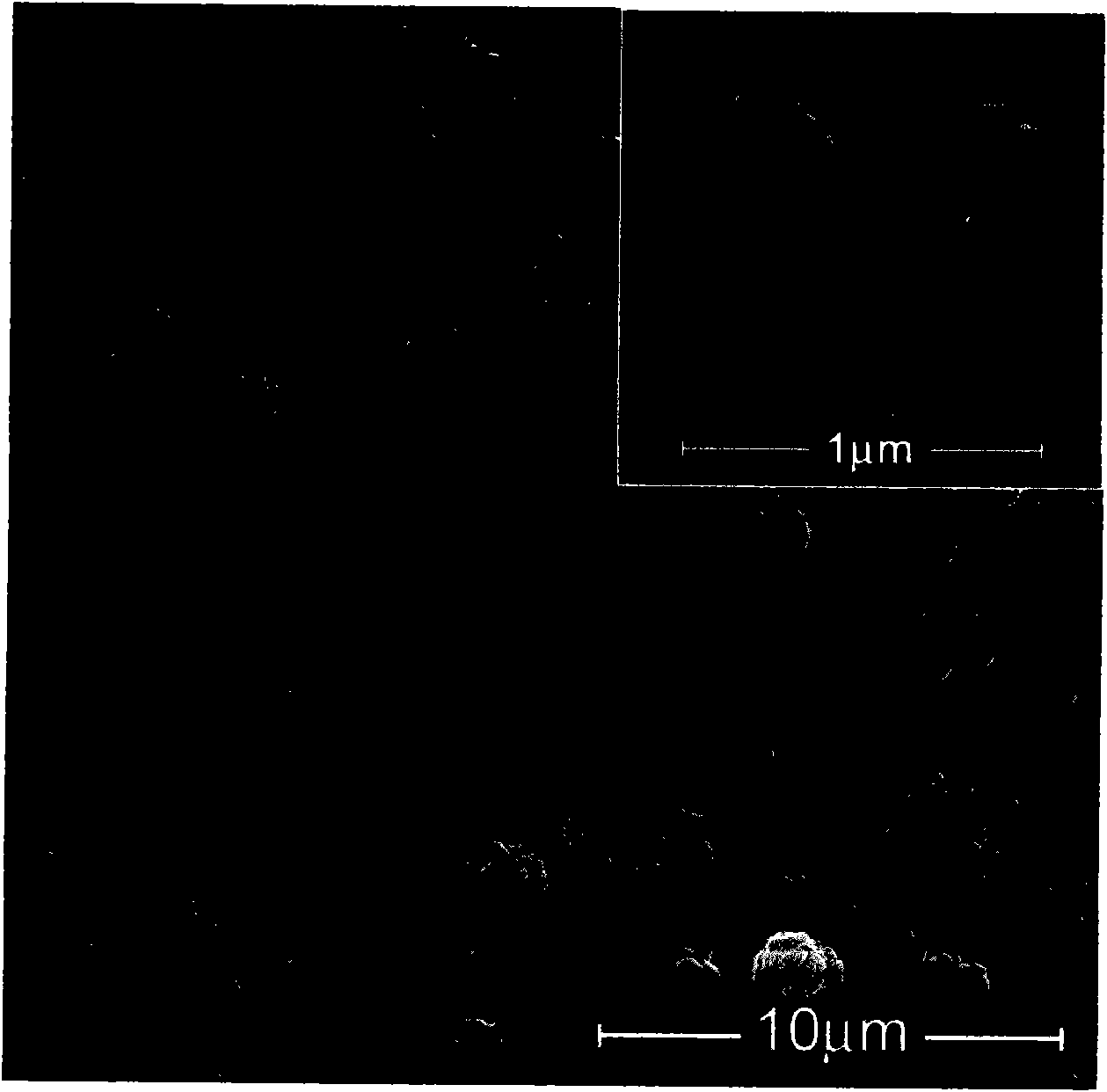

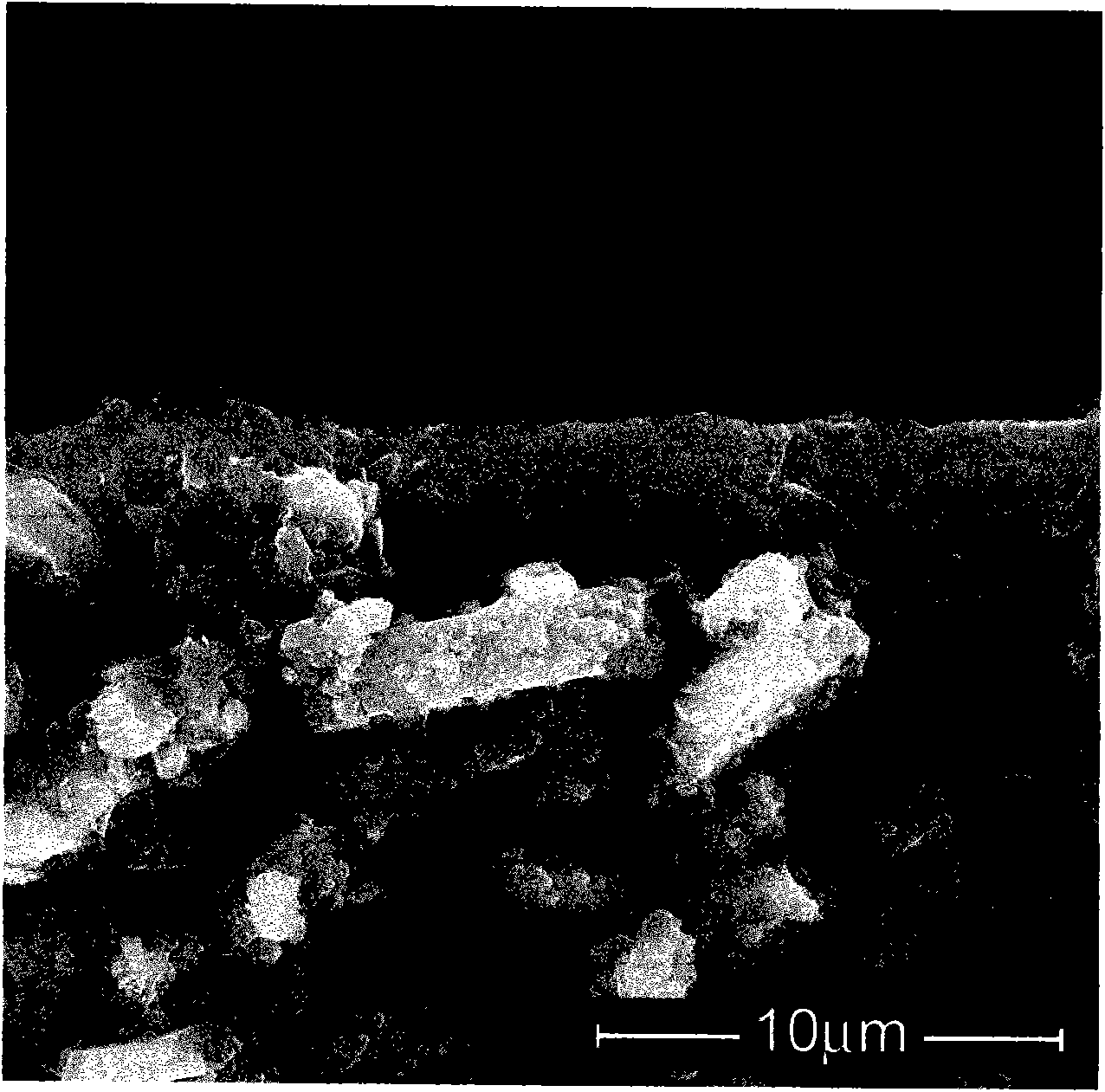

[0019] In-situ aging-microwave heating method (see Chinese patent CN1778677A for details on the synthesis method, published on May 31, 2006) in porous α-Al 2 o 3 The X-ray diffraction pattern of the FAU type molecular sieve membrane synthesized on the outer surface of the carrier tube (12mm in outer diameter, 9mm in inner diameter, and a porosity of about 30%) is as follows figure 1 As shown, there are only FAU type molecular sieves and carrier α-Al in the figure 2 o 3 Diffraction peaks of other impurity phases. Scanning electron micrograph of FAU type molecular sieve membrane ( figure 2 , image 3 ) shows that the surface of the carrier is covered with a continuous and dense molecular sieve membrane with a thickness of about 5 μm. Molecular sieve crystals are uniform in size and closely connected. Its silicon-aluminum ratio is about 1.5 as measured by an energy disper...

Embodiment 2

[0024] Embodiment 2: the reaction of dimethyl carbonate and n-butanol

[0025] Transesterification of dimethyl carbonate with n-butanol Figure 5 carried out in the experimental setup shown. After 0.1mol dimethyl carbonate and 0.4mol n-butanol are fully mixed in mixer 1, they are vaporized in vaporizer 3 through injection pump 2 at a flow rate of 1 mL / min. The mixed steam enters the 2 Catalyst fixed bed reactor 5 reacts under the conditions of 413K and 0.2MPa. After the reaction, the steam enters the FAU-type molecular sieve membrane (in-situ aging-microwave heating synthesis, the effective membrane area is 22cm 2 ) in the membrane module 6, the separation is realized under the conditions of 393K and 0.2MPa. The permeate side of the membrane module is evacuated by a vacuum pump and condensed with liquid nitrogen, and the raw material liquid is returned to the mixer through the condenser 7. After the reaction was carried out for 4 hours, the composition of the reaction sys...

Embodiment 3

[0026] Embodiment 3: the reaction of dimethyl carbonate and n-butanol

[0027] According to the same operation as in Example 2, except that the FAU type molecular sieve membrane in the membrane module is synthesized by a two-step in-situ hydrothermal method (the synthesis method is detailed in Chinese Patent CN101112676A, published on January 30, 2008), its silicon-aluminum ratio The energy dispersive X-ray fluorescence spectrometer was determined to be 1.2. After the reaction was carried out for 4 hours, the conversion rate of dimethyl carbonate was 81.5%, the selectivity of dibutyl carbonate was 82.8%, and the yield of dibutyl carbonate was 67.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com