Preparation method of carbon-based titanium dioxide composite material of complex porous structure

A porous structure and titanium dioxide technology, applied in chemical instruments and methods, other chemical processes, optics, etc., can solve problems such as stability, photoelectric properties, and catalytic properties, and achieve green and environmentally friendly manufacturing costs, simple and easy preparation methods, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

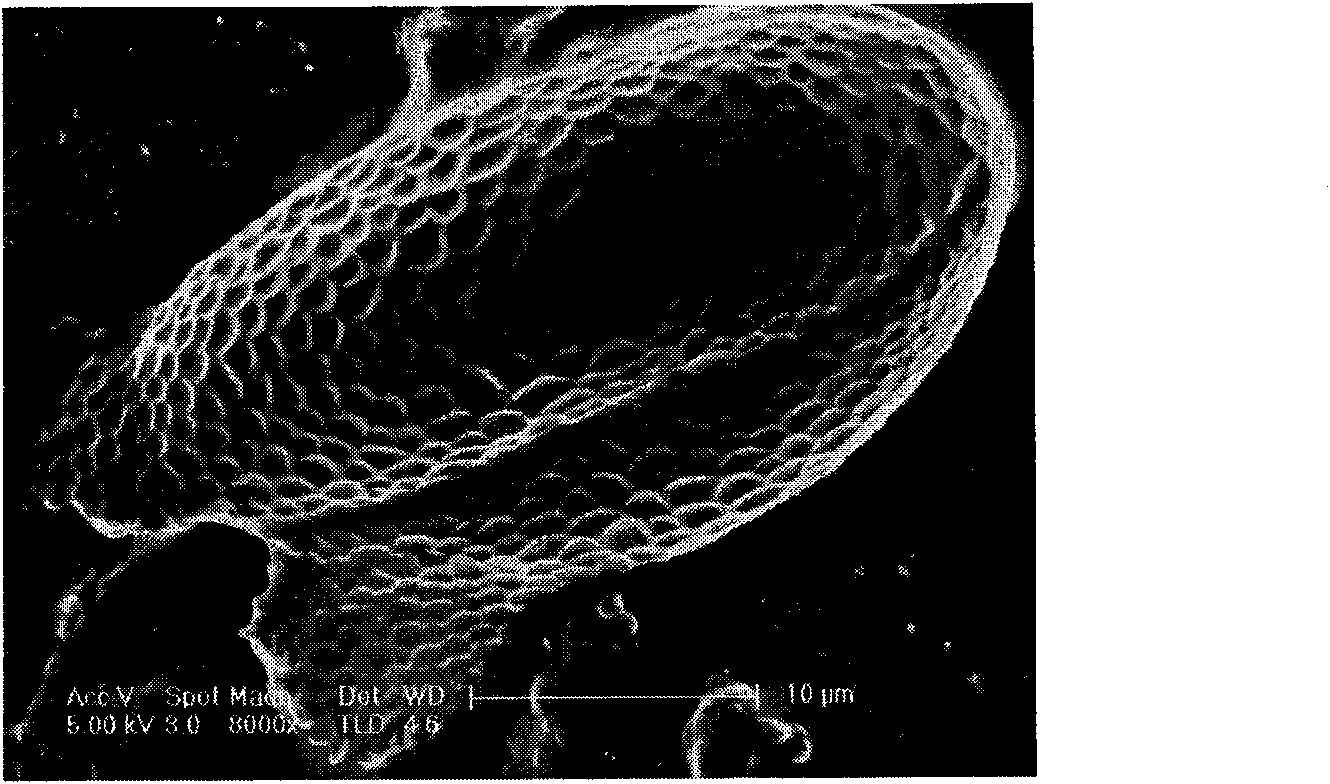

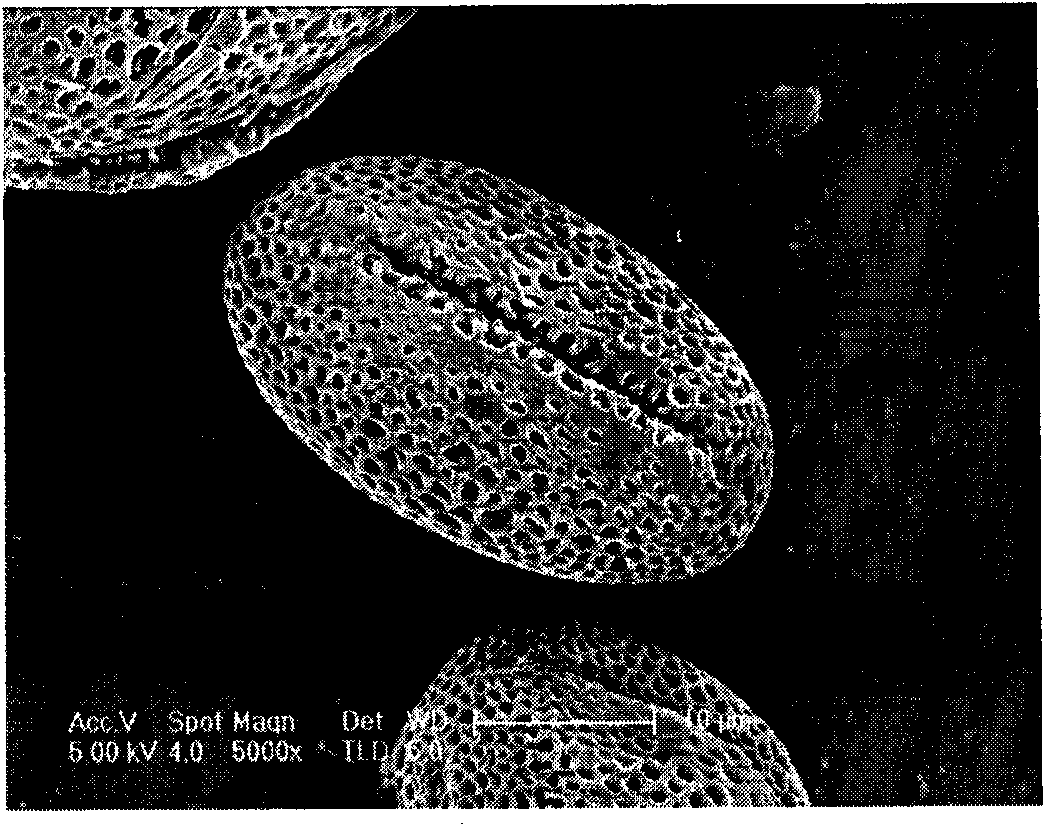

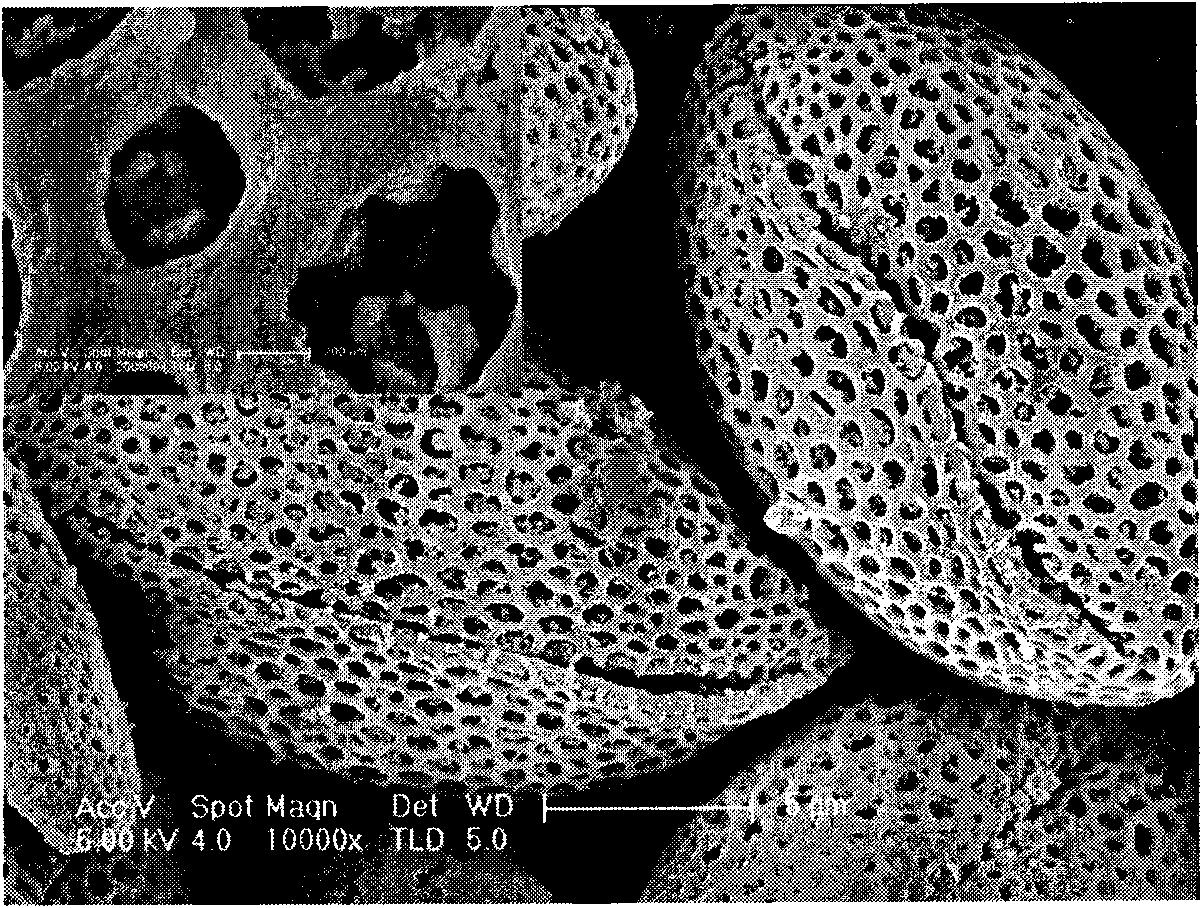

[0024] The natural rapeseed pollen with complex porous fine structure was selected as the biological template material, and the scanning electron microscope photos of natural rapeseed pollen grains are as follows: figure 1 shown. Put the natural rapeseed pollen in the ethanol solution for ultrasonic dispersion treatment, after the color of the solution turns yellow, carry out suction filtration, and wash with absolute ethanol during the suction filtration process, collect the yellow powdery solid, blow dry at room temperature, Obtain pretreated clean pollen. Scanning electron micrographs of rapeseed pollen grains washed with absolute ethanol are as follows: figure 2 shown.

[0025] The titanium sol impregnation solution was prepared according to the molar ratio of tetrabutyl titanate, absolute ethanol, alcohol amine and water as 1:40:1:1. Dissolve 8 mL of tetrabutyl titanate in absolute ethanol, add alcohol amine under vigorous stirring, and after stirring at room temperat...

Embodiment 2

[0030] Select natural rapeseed pollen with complex porous and fine structure as biological template material, place it in ethanol solution for ultrasonic dispersion treatment, and perform suction filtration after the color of the solution turns yellow, and wash with absolute ethanol during the suction filtration process, collect yellow The powdery solid is air-dried at room temperature to obtain pretreated clean pollen.

[0031] Prepare titanium sol impregnation solution according to the molar ratio of tetrabutyl titanate, absolute ethanol, alcohol amine and water as 1:40:1:1, dissolve 8mL tetrabutyl titanate in absolute ethanol, and stir vigorously Alcoholamine was added, stirred at room temperature for 1 hour, then a mixture of water and ethanol was added, and stirred for 1 hour to obtain a stable and transparent titanium sol. Immerse the pretreated pollen in the titanium dioxide sol at room temperature for 16 hours, keep stirring continuously during the impregnation process...

Embodiment 3

[0034] Select natural rapeseed pollen with complex porous and fine structure as biological template material, place it in ethanol solution for ultrasonic dispersion treatment, and perform suction filtration after the color of the solution turns yellow, and wash with absolute ethanol during the suction filtration process, collect yellow The powdery solid is air-dried at room temperature to obtain pretreated clean pollen.

[0035] Prepare titanium sol impregnation solution according to the molar ratio of tetrabutyl titanate, absolute ethanol, alcohol amine and water as 1:40:1:1, dissolve 8mL tetrabutyl titanate in absolute ethanol, and stir vigorously Alcoholamine was added, stirred at room temperature for 1 hour, then a mixture of water and ethanol was added, and stirred for 1 hour to obtain a stable and transparent titanium sol. Immerse the pollen pretreated above in the titanium dioxide sol at room temperature for 24 hours, keep stirring continuously during the impregnation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com