Electrothermal film and manufacturing method thereof

A manufacturing method and technology of electrothermal film, which are applied in the direction of coating resistance materials, heating element materials, and resistors with lead-out terminals, etc., can solve problems such as low efficiency, and achieve the effects of fast heating, stable film layer, and good physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

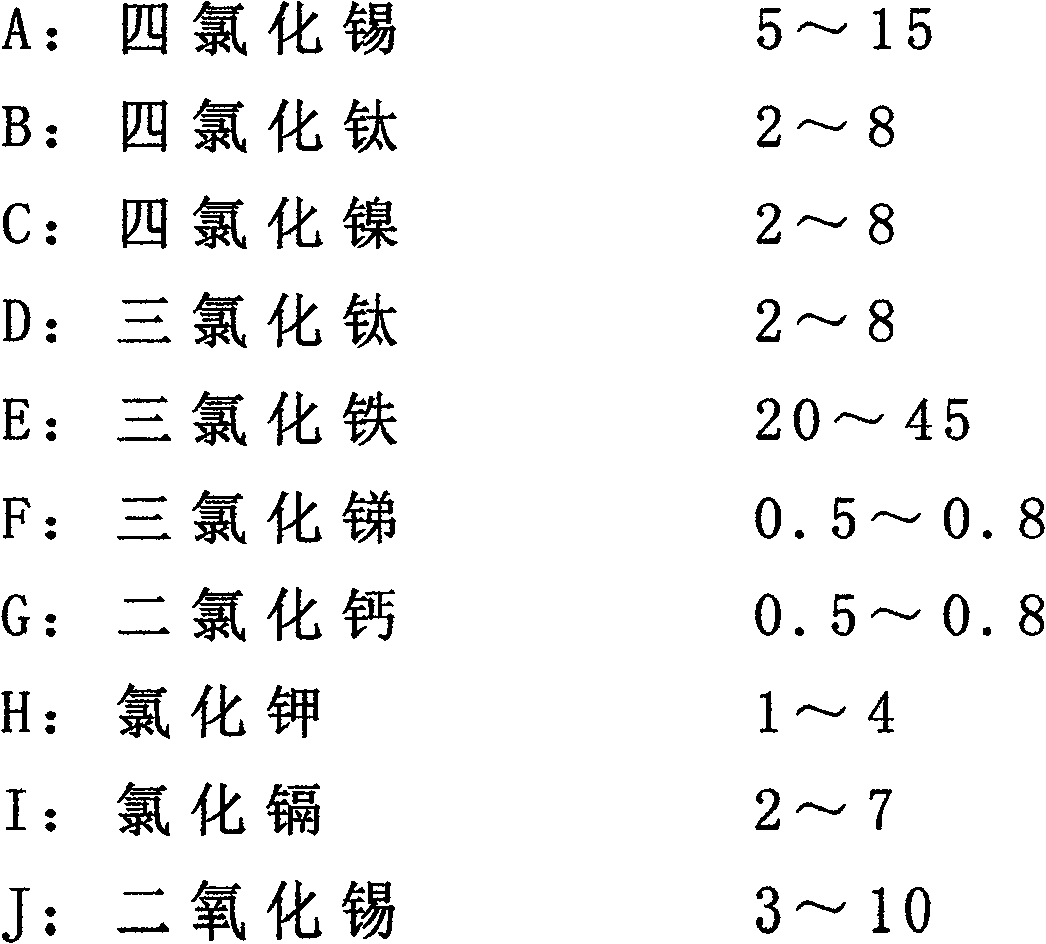

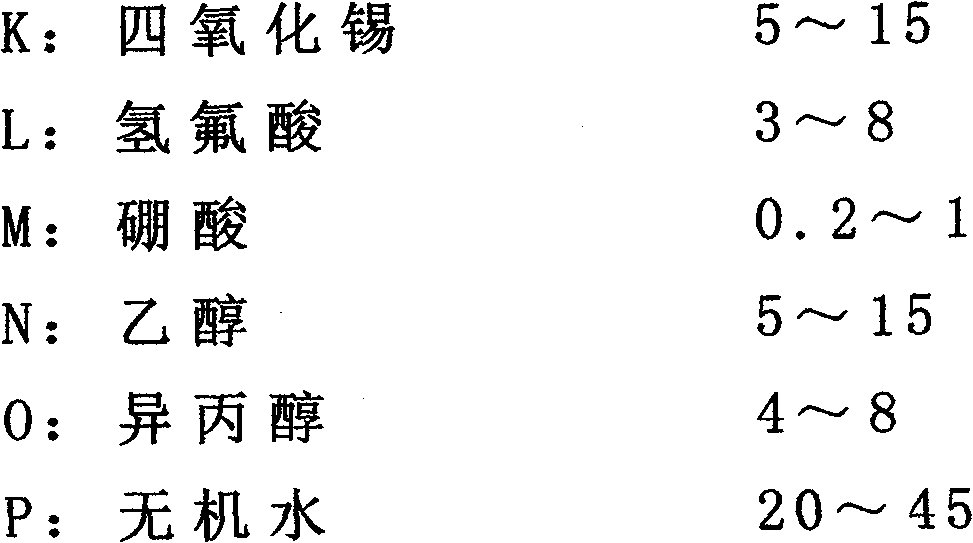

[0018] The first embodiment of the present invention is as follows:

[0019] 1. Take (each component by mass percentage) tin tetrachloride 10, titanium tetrachloride 3, nickel tetrachloride 3, titanium trichloride 3, ferric chloride 21, antimony trichloride 0.8, dichloride Calcium 0.5, potassium chloride 2, cadmium chloride 4, tin dioxide 5, tin tetroxide 6, hydrofluoric acid 7, boric acid 1, ethanol 6, isopropanol 6, inorganic water 21.7 Put into a mixing heater and mix and heat to 75°C, stir evenly to dissolve all the solid raw materials, and filter the solution to obtain an electrothermal film treatment solution when the solution is cooled to -1°C.

[0020] 2. Take a heating furnace, the furnace core is made of silicon carbide, the heating power is 13KW, the furnace temperature is 700 ℃, the quartz glass (electric heating film carrier) is put into the furnace and heated to 700 ℃, and the electric heating is heated by the negative pressure spray method. The film is coated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com