Method for preparing high-load tribology DLC membrane on surface of titanium

A titanium metal and tribological technology, which is applied in the field of preparation of high-performance surface films, can solve problems such as poor friction and wear properties, and achieve the effect of improving bearing capacity, high toughness, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

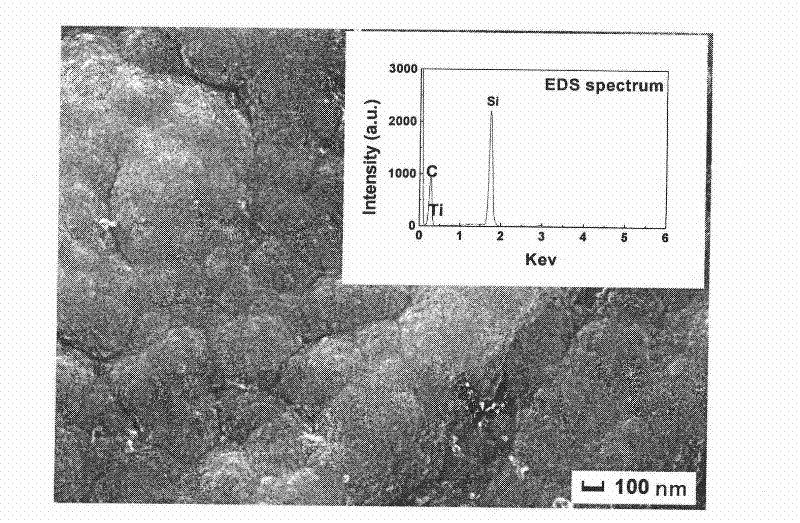

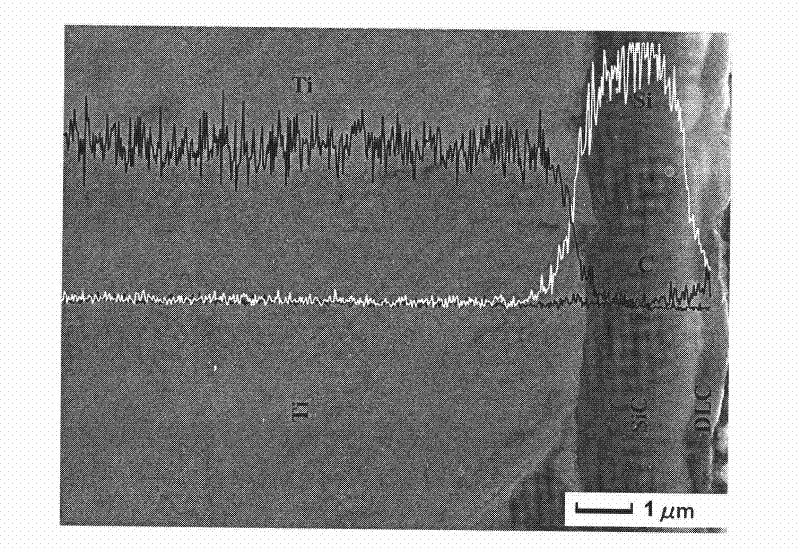

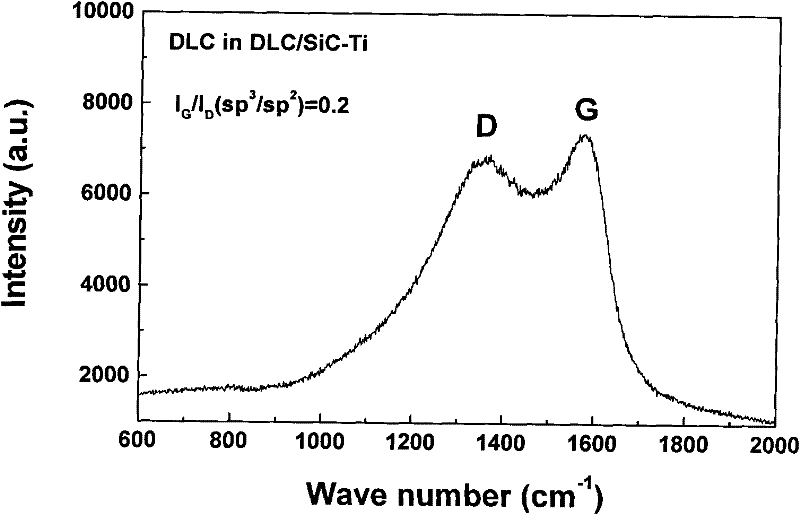

[0029] Such as Figure 1-7 shown.

[0030] A method for preparing high-load tribology DLC (diamond-like carbon) film on titanium metal surface, it may further comprise the steps:

[0031] First, clean the titanium metal as the substrate and the SiC (silicon carbide) of the target;

[0032] Secondly, use the radio frequency magnetron sputtering method to deposit SiC on the surface of the substrate to form the SiC thin film intermediate layer;

[0033] Finally, a DLC film is formed on the SiC film intermediate layer by DC magnetron sputtering.

[0034] The cleaning of the target material and the substrate refers to removing the dirt on the surface of the substrate by means of sandpaper and polishing, and then immersing in an organic solvent (such as acetone, absolute ethanol, etc.) for ultrasonic cleaning; Put the base material into the main sputtering chamber and the sampling chamber to clean the target and substrate by radio frequency backsputtering; after the air pressure ...

Embodiment 2

[0038] Substrate Ti, intermediate layer film SiC, surface film DLC. When carrying out according to Example 1, a JGP560CVI ultra-high vacuum multifunctional magnetron sputtering apparatus is used to prepare a thin film. The background pressure when preparing SiC thin film and DLC thin film is 2.5×10 -5 Pa and substrate temperature are all at room temperature, and the target-substrate distance is 70mm. The technology used to deposit SiC thin film is radio frequency (RF) magnetron sputtering technology, the target material is SiC, the pressure of working gas (argon) is 2.1Pa, the flow rate of argon gas is 55 sccm, the sputtering power is 200W, and the sputtering time is 120min. The technology used when preparing the DLC film is direct current (DC) magnetron sputtering technology, the target material is graphite (Gr), the pressure of working gas (argon) is 1.1Pa, the flow rate of argon gas is 65sccm, and the sputtering power is 100W. Sputtering time is 120min.

[0039] The DLC...

Embodiment 3

[0044] Substrate Ti, intermediate layer film SiC, surface film DLC. When the steps described in Example 1 are carried out, a JGP560CVI ultra-high vacuum multifunctional magnetron sputtering apparatus is used to prepare a thin film. The background pressure when preparing SiC film and DLC film is 2.5×10 -5 Pa and substrate temperature are all at room temperature, and the target-substrate distance is 70 mm. The technology used to deposit SiC thin film is radio frequency (RF) magnetron sputtering technology, the target material is SiC, the pressure of working gas (argon) is 2.0Pa, the flow rate of argon gas is 65sccm, the sputtering power is 200W, and the sputtering time is 120min. The technology used when preparing the DLC film is direct current (DC) magnetron sputtering technology, the target material is graphite (Gr), the pressure of working gas (argon) is 1.0Pa, the flow rate of argon gas is 65sccm, and the sputtering power is 100W. Sputtering time is 120min.

[0045] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com