Gold nanoparticle loaded mesoporous titanium oxide composite film and preparation thereof

A technology of mesoporous titanium oxide and gold nanoparticles, which is used in instruments, nonlinear optics, optics, etc. to achieve uniform distribution, uniform size, and avoid heat accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of mesoporous titanium oxide film: Dissolve 0.33 g of surfactant F127 in 18.4 g of ethanol and stir for 3 hours. Then, 1.7 g of titanium tetrachloride was slowly added dropwise to the above solution, and stirring was continued for 2 hours. The obtained sol was placed in an environment with a relative humidity of 85%, and pulled to form a film at a rate of 70 cm / min.

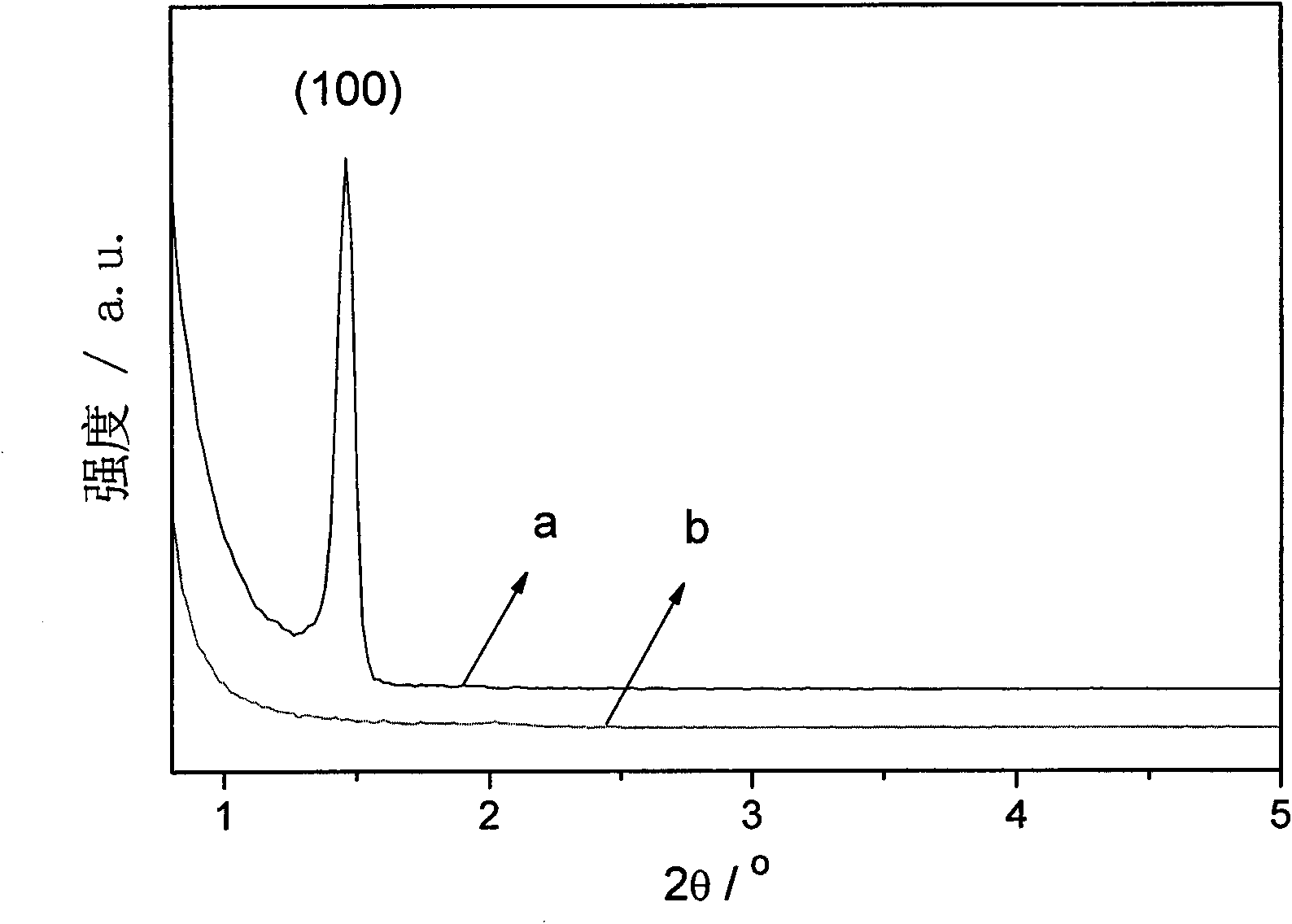

[0045] After drying at room temperature for 24 hours, the small-angle XRD pattern of the film is as shown in the accompanying drawings figure 1 (a) as shown, figure 1 (a) is the XRD curve of the mesoporous titanium oxide film in the two-dimensional hexagonal mesoporous phase. The diffraction peak in curve (a) corresponds to the (100) plane diffraction peak of the two-dimensional hexagonal mesoporous phase.

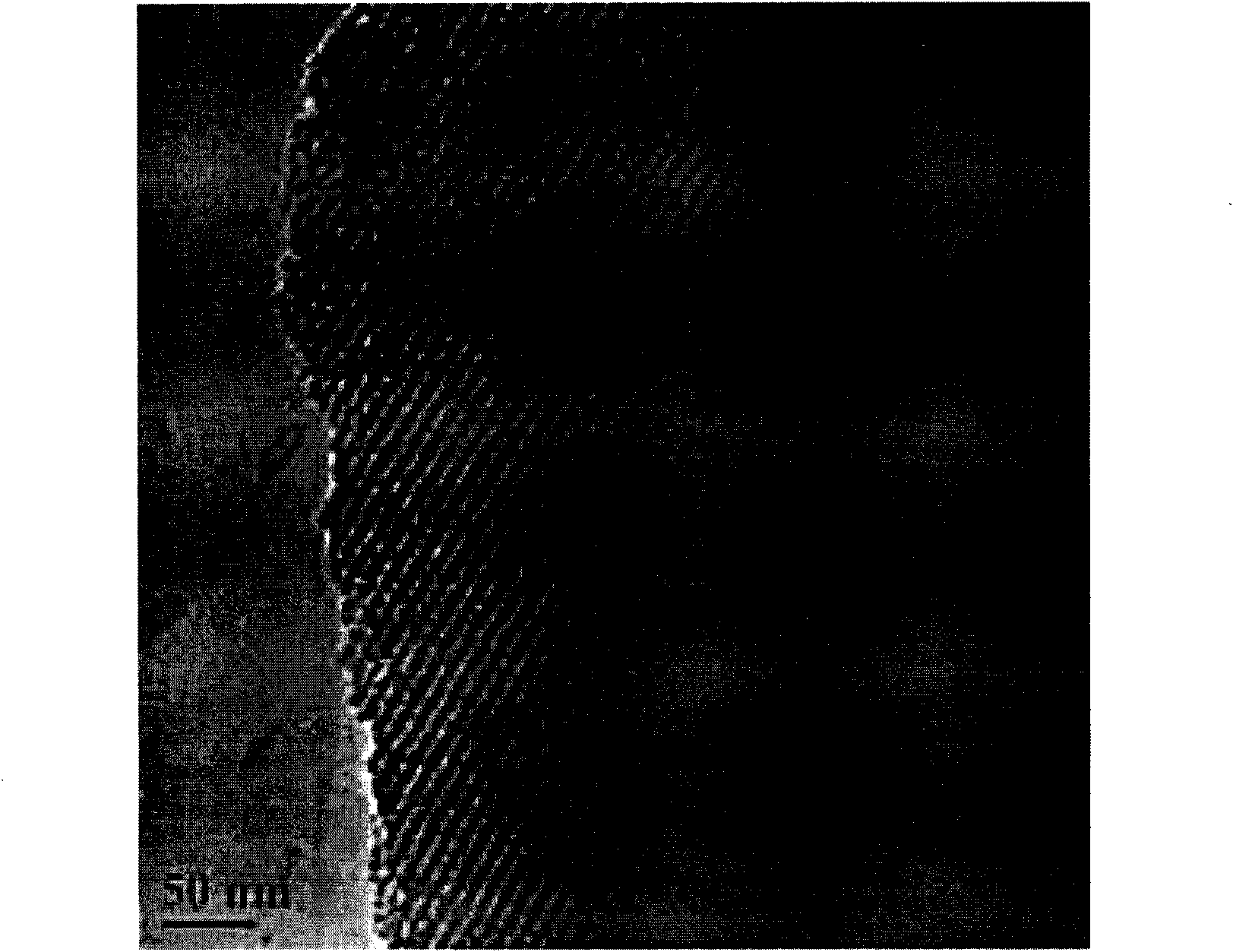

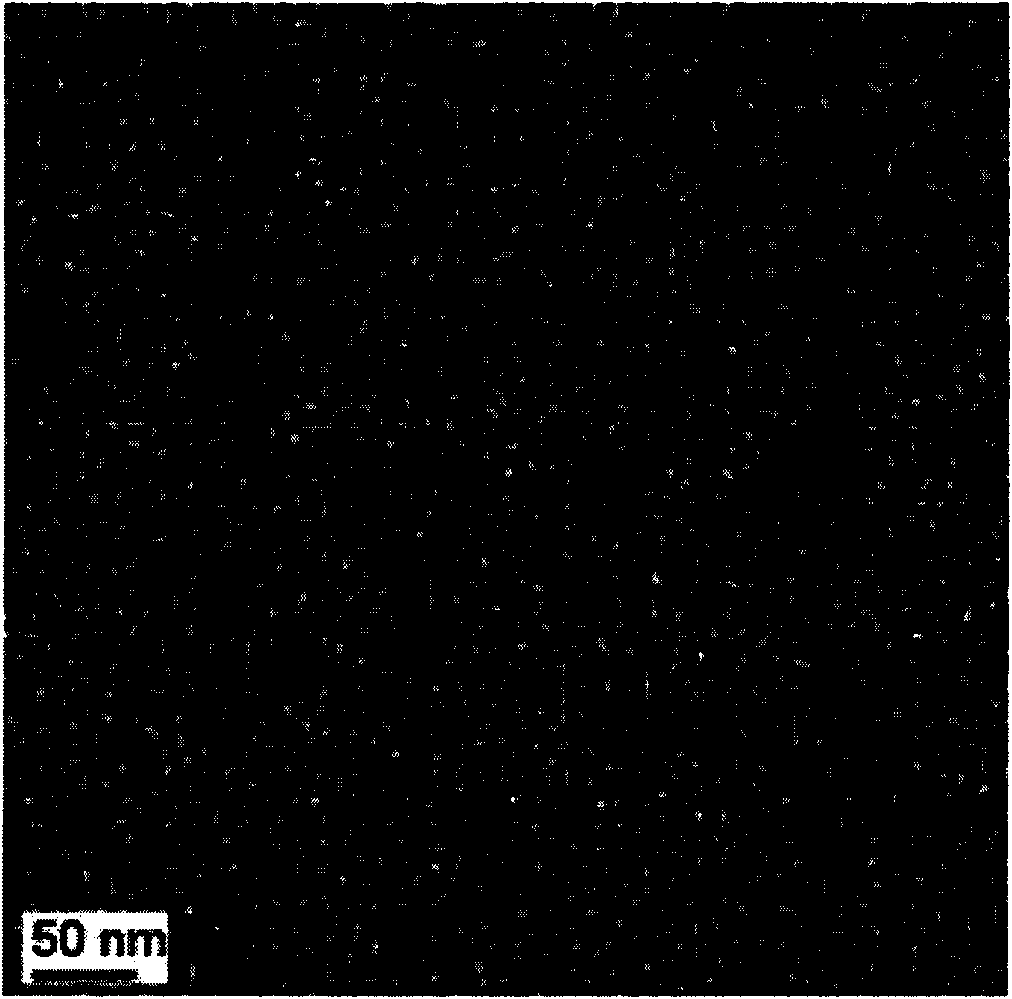

[0046] The transmission electron micrograph is as in the attached drawings figure 2 As shown, the film has a two-dimensional hexagonal mesoporous structure. The ordered mesoporous titanium ...

Embodiment 2

[0054] 1. Heat-treat the ordered mesoporous titanium oxide film dried at room temperature (heat up to 400°C at a rate of 2°C / min, keep it for 4 hours, and cool down with the furnace) to remove the surfactant F127. According to BET detection, the pore size of the two-dimensional hexagonal mesoporous structure prepared in this example is 6nm; the pore volume is 0.16cm 3 / g.

[0055] 2. Immerse the mesoporous film from which the surfactant has been removed into a 0.5mM chloroauric acid aqueous solution, heat it to 70°C, and slowly drop in sodium hydroxide aqueous solution at a rate of 1.5ml / min (sodium hydroxide aqueous solution, sodium hydroxide The concentration is 1M), while stirring, when the pH value of the above-mentioned mixed solution reaches 7, the dropwise addition of the sodium hydroxide aqueous solution is stopped. Then, take the film out of the mixed solution, rinse the surface with deionized water, dry at room temperature, and put it into a hydrogen / argon mixed atmosph...

Embodiment 3

[0057] 1. Preparation of mesoporous titanium oxide film: Dissolve 0.33 g of surfactant F127 in 18.4 g of ethanol and stir for 3 hours. Then, 1.7 g of titanium tetrachloride was slowly added dropwise to the above solution, and stirring was continued for 2 hours. The resulting sol was placed in an environment with a relative humidity of 85%, and pulled into a film at a rate of 70 cm / min.

[0058] 2. Heat the ordered mesoporous titanium oxide film dried at room temperature (heat up to 450°C at a rate of 2°C / min, keep it for 5 hours, and cool down with the furnace) to remove the surfactant F127. According to BET detection, the pore size of the two-dimensional hexagonal mesoporous structure prepared in this example is 6nm; the pore volume is 0.16cm 3 / g.

[0059] 3. Immerse the mesoporous film from which surfactant has been removed into a 5mM chloroauric acid aqueous solution, heat to 80°C, slowly add sodium hydroxide aqueous solution dropwise while stirring, and stop the dropwise addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com