Alkyl-iminodisuccinate chelating surfactant and method for synthesizing same

A technology of alkyliminodisuccinate, alkyliminodisuccinic acid, applied in chemical instruments and methods, dissolution, chemical/physical process, etc., can solve pipeline blockage or form new deposits on the surface, The builder effect of sodium metasilicate is not very good, the production cost of washing products increases, etc., to achieve the effects of excellent surface activity and chelating ability, low price and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

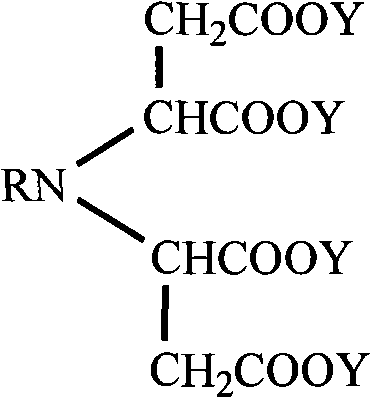

[0024] Alkyl imino disuccinate chelating surfactant, its structural formula is as shown in the following formula:

[0025]

[0026] where R is C 12 h 25 , Y is Na.

[0027] The preparation method of alkylimino disuccinate chelating surfactant is as follows:

[0028] (1) according to the mol ratio dodecylamine of substance: maleic anhydride: the ratio of sodium hydroxide=1:2:4 takes by weighing fatty primary amine 21.0Kg, maleic anhydride 22.2Kg and sodium hydroxide 18.1Kg, first hydrogen Sodium oxide is made into the aqueous solution that mass concentration is 25%, after adding maleic anhydride in the alkali solution and dissolving, then add dodecylamine, then add 63.7Kg ethanol in the above-mentioned mixed solution, finally add and account for 6 % copper chloride as catalyst.

[0029] (2) Add the above solution into a high-pressure reactor equipped with a stirring device for reaction, react at a reaction temperature of 140° C. and a reaction pressure of 0.3 MPa for 20 ...

Embodiment 2

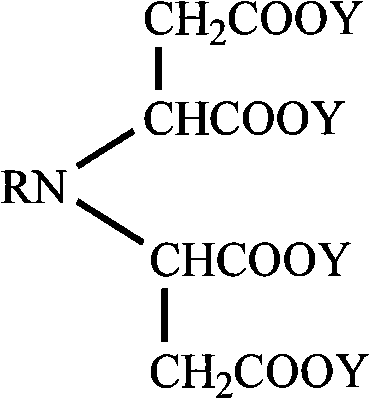

[0032] Alkyl imino disuccinate chelating surfactant, its structural formula is as shown in the following formula:

[0033]

[0034] where R is C 18 h 37 , Y is K.

[0035] The preparation method of alkylimino disuccinate chelating surfactant is as follows:

[0036] (1) take fatty primary amine 23.2Kg, maleic anhydride 23.4Kg and potassium hydroxide 24.15Kg in the ratio of the mol ratio octadecylamine of substance: maleic anhydride: potassium hydroxide=1: 3: 5, first hydrogen Potassium oxide is made into an aqueous solution with a mass concentration of 35%, then maleic anhydride is added to the alkali solution for dissolution, then octadecylamine is added, then 45Kg ethanol is added to the above mixed solution, and finally 5% of the total mass of the reactants is added cuprous chloride as a catalyst.

[0037] (2) Add the above solution into a high-pressure reactor equipped with a stirring device for reaction, react at a reaction temperature of 120° C. and a reaction pres...

Embodiment 3

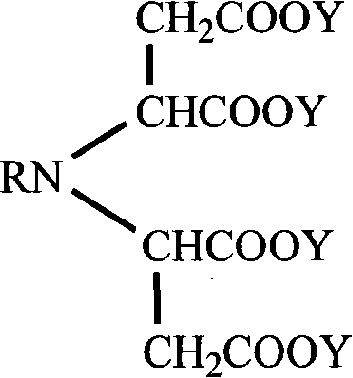

[0040] Alkyl imino disuccinate chelating surfactant, its structural formula is as shown in the following formula:

[0041]

[0042] where R is C 16 h 33 , Y is NH 4 .

[0043] The preparation method of alkylimino disuccinate chelating surfactant is as follows:

[0044] (1) Take by weighing fatty amine 20.8Kg, maleic anhydride 31.2Kg and sodium hydroxide 27.57Kg in the ratio of the mol ratio hexadecylamine: maleic anhydride: sodium hydroxide=1: 4: 8, first hydrogen oxidize Sodium is made into the aqueous solution that mass concentration is 27%, after adding maleic anhydride in the alkali solution and dissolving, then add hexadecylamine, then add 76Kg ethanol in the above-mentioned mixed solution, finally add and account for reactant gross mass 4% Copper acetate was used as a catalyst.

[0045] (2) Add the above solution into a high-pressure reactor equipped with a stirring device for reaction, react at a reaction temperature of 110° C. and a reaction pressure of 2 MPa f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com