Gel-type extracting agent for drilling fluid or well completion fluid and preparation method thereof

A kind of cutting agent and gel-type technology, which is applied in the field of gel-type cutting agent and its preparation, can solve the problems of weak sand-carrying ability, large environmental pollution, difficult biodegradation, etc., and achieve excellent lubricity and inhibition, Improved cutting performance and strong sand-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 7.5g surfactant OP-10 in 142.5ml tap water, prepare 5wt% surfactant OP-10 aqueous solution;

[0040] (2) Add 150g 5wt% surfactant OP-10 aqueous solution into the reaction kettle, add 100g xanthan gum while stirring, and activate the reaction for 7h at a temperature of 80-90°C;

[0041] (3) After the activated product is dried at 105°C, crushed and passed through a 200-mesh sieve, an intermediate product is obtained.

[0042] (4) Take 40.0g of the intermediate product and compound it with 50.0g of HV-CMC and 10.0g of potassium formate to obtain 100.0g of the gel-type cutting agent product.

Embodiment 2

[0044] (1) Add 7.5g surfactant AEO-3 in 142.5ml tap water, prepare 5wt% surfactant AEO-3 aqueous solution;

[0045](2) Add 150g of 5wt% surfactant AEO-3 aqueous solution into the reaction kettle, add 100g of xanthan gum while stirring, and activate the reaction for 7h at a temperature of 80-90°C;

[0046] (3) After the activated product is dried at 105°C, crushed and passed through a 200-mesh sieve, an intermediate product is obtained.

[0047] (4) Take 50.0g of the intermediate product and compound it with 40.0g of LV-CMC and 10.0g of sodium formate to obtain 100.0g of the gel-type cutting agent product.

Embodiment 3

[0049] (1) Add 7.5g surfactant AEO-9 to 142.5ml tap water to prepare 5wt% surfactant AEO-9 aqueous solution;

[0050] (2) Add 150g of 5wt% surfactant AEO-9 aqueous solution into the reaction kettle, add 100g of xanthan gum while stirring, and activate the reaction for 7h at a temperature of 80-90°C;

[0051] (3) After the activated product is dried at 105°C, crushed and passed through a 200-mesh sieve, an intermediate product is obtained.

[0052] (4) Take 60.0g of the intermediate product and compound it with 30.0g of CMS and 10.0g of citric acid to obtain 100.0g of the gel-type cutting agent product.

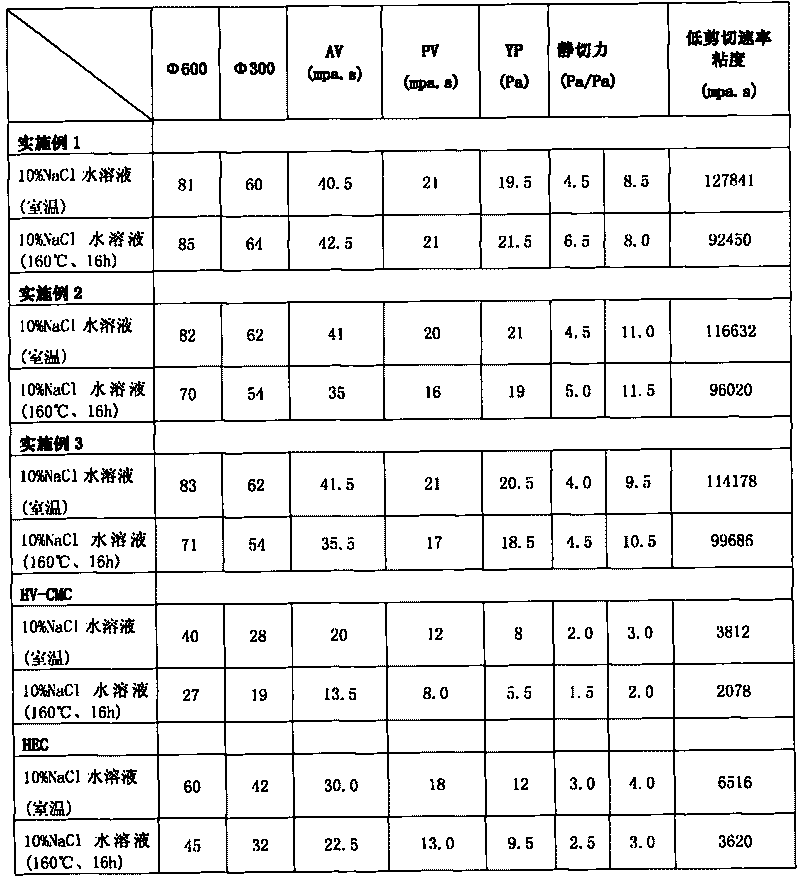

[0053] The performance evaluation method of embodiment product:

[0054] 1. Evaluation of the gelling performance of the products of the examples

[0055] Add 148ml of water into a 200ml beaker, turn on the stirrer at a speed of 3000r / min, and add 2.0g of the product of the example while stirring. After the product is completely added, continue stirring for 10min, and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com