Method for producing R-mandelic acid and derivates thereof by biocatalysis

A biocatalysis method, mandelic acid technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficult industrialization, small processing capacity, low activity, etc., and achieve easy industrial production and mild reaction conditions. , the effect of high hydrolase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

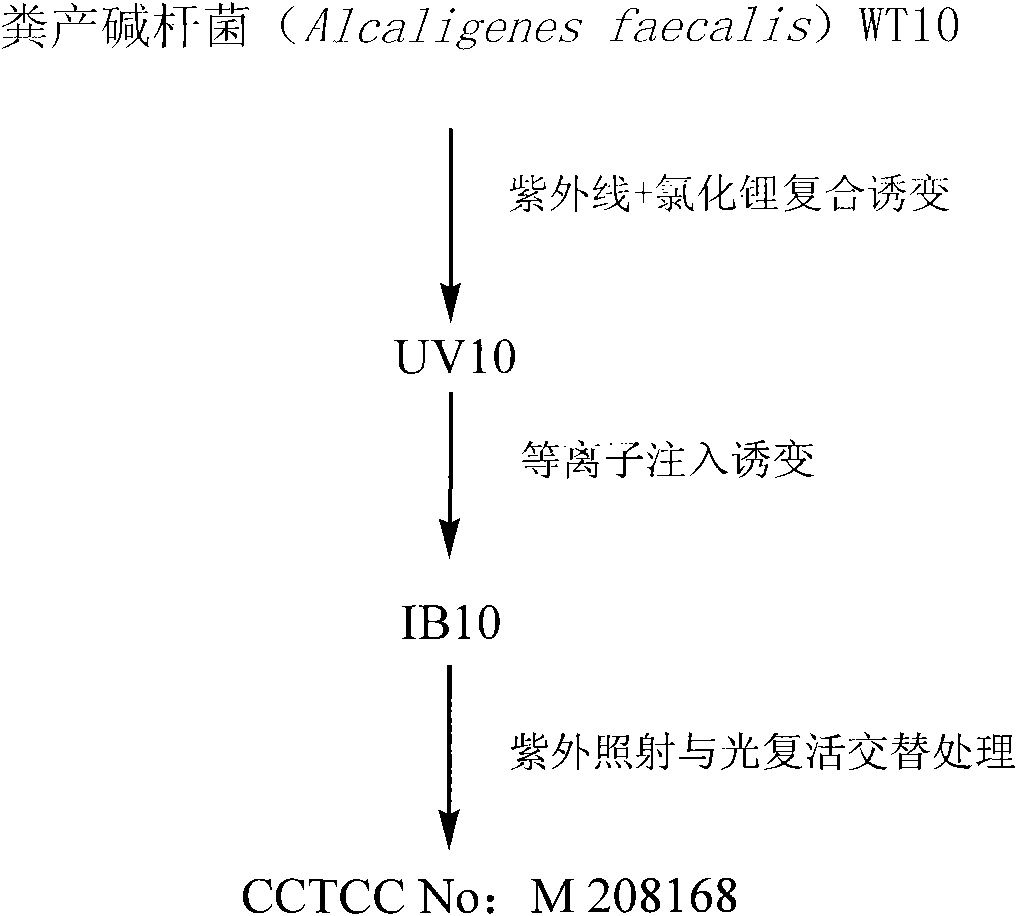

[0031] Embodiment 1: Screening and identification of bacterial strains

[0032] 1. Screening of strains

[0033] About 80 soil samples were collected from the sewage outlets of factories, garbage dumps and near the laboratory in various parts of Zhejiang Province for strain screening.

[0034]The composition of the final concentration of the enrichment medium: (NH 4 ) 2 SO 4 1g / L, KH 2 PO 4 0.2g / L, Na 2 HPO 4 0.8g / L, MgSO 4 ·7H 2 O 0.2g / L, CaCl 2 0.1g / L, FeCl 3 0.005g / L, pH7.0, solvent is water.

[0035] The composition of the final concentration of the slant medium: glucose 10g / L, yeast extract 10g / L, K 2 HPO 4 5g / L, MgSO 4 ·7H 2 O 0.2g / L, FeSO 4 0.03g / L, NaCl 1g / L, agar 20g / L, pH7.0, solvent is water.

[0036] The composition of the final concentration of the enzyme production medium: glucose 10g / L, yeast extract 10g / L, K 2 HPO 4 5g / L, MgSO 4 ·7H 2 O 0.2g / L, FeSO 4 0.03g / L, NaCl 1g / L, caprolactam 1g / L, pH 7.0, solvent is water.

[0037] Add 2mM...

Embodiment 2

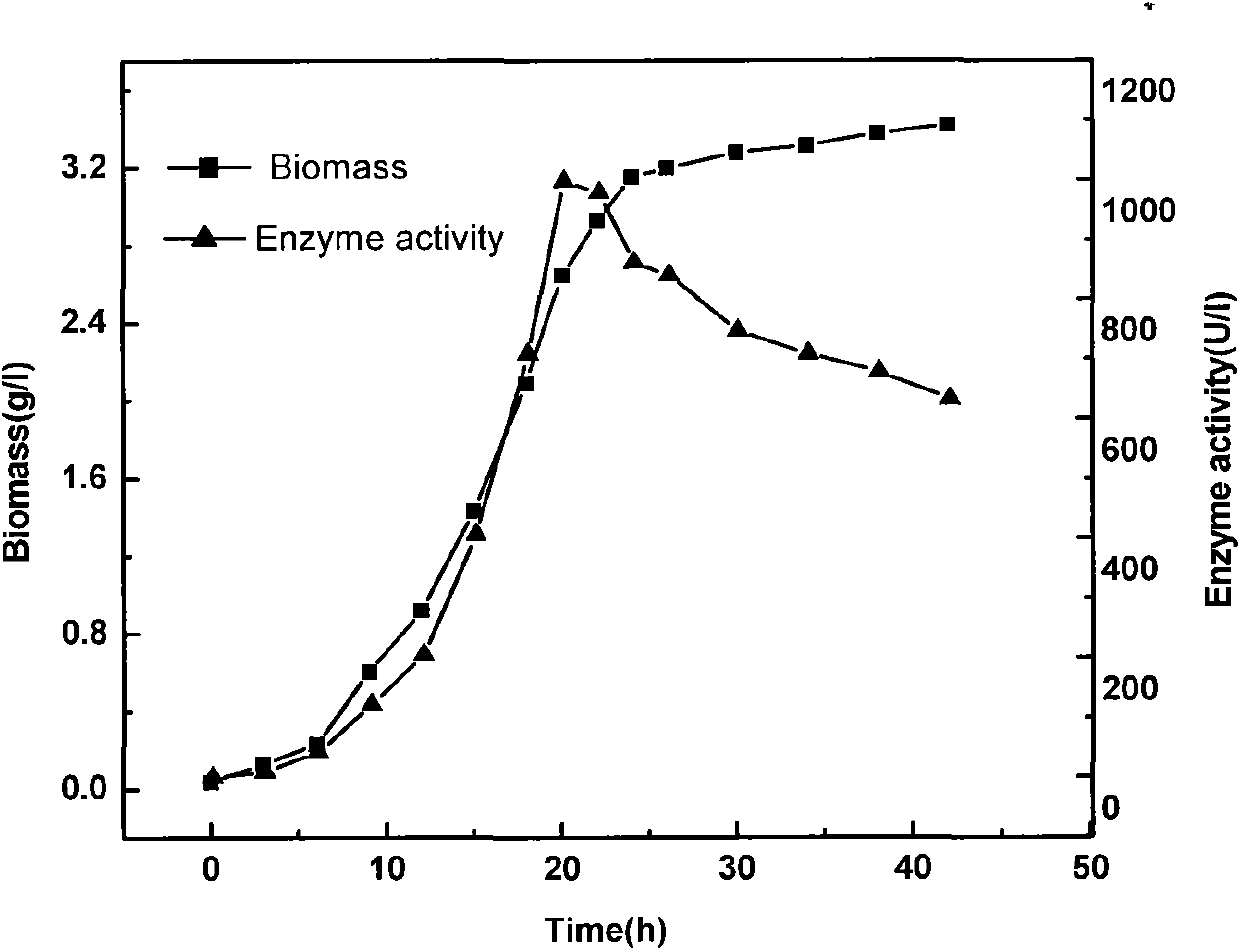

[0054] 1. Cultivation of cells containing nitrilase

[0055] The composition of the final concentration of the seed medium: ammonium acetate 10g / L, yeast extract 6g / L, dipotassium hydrogen phosphate 5g / L, sodium chloride 1g / L, magnesium sulfate 0.2g / L, and the solvent is water. The CCTCC No: M 208168 strain was inoculated into the seed medium and cultured at 30°C for 28 hours to obtain the seed solution.

[0056] Final concentration composition of enzyme-producing fermentation medium: ammonium acetate 12.14g / L, yeast extract 7.79g / L, n-butyronitrile 3.29g / L, dipotassium hydrogen phosphate 5g / L, sodium chloride 1g / L, magnesium sulfate 0.2g / L, the solvent is water.

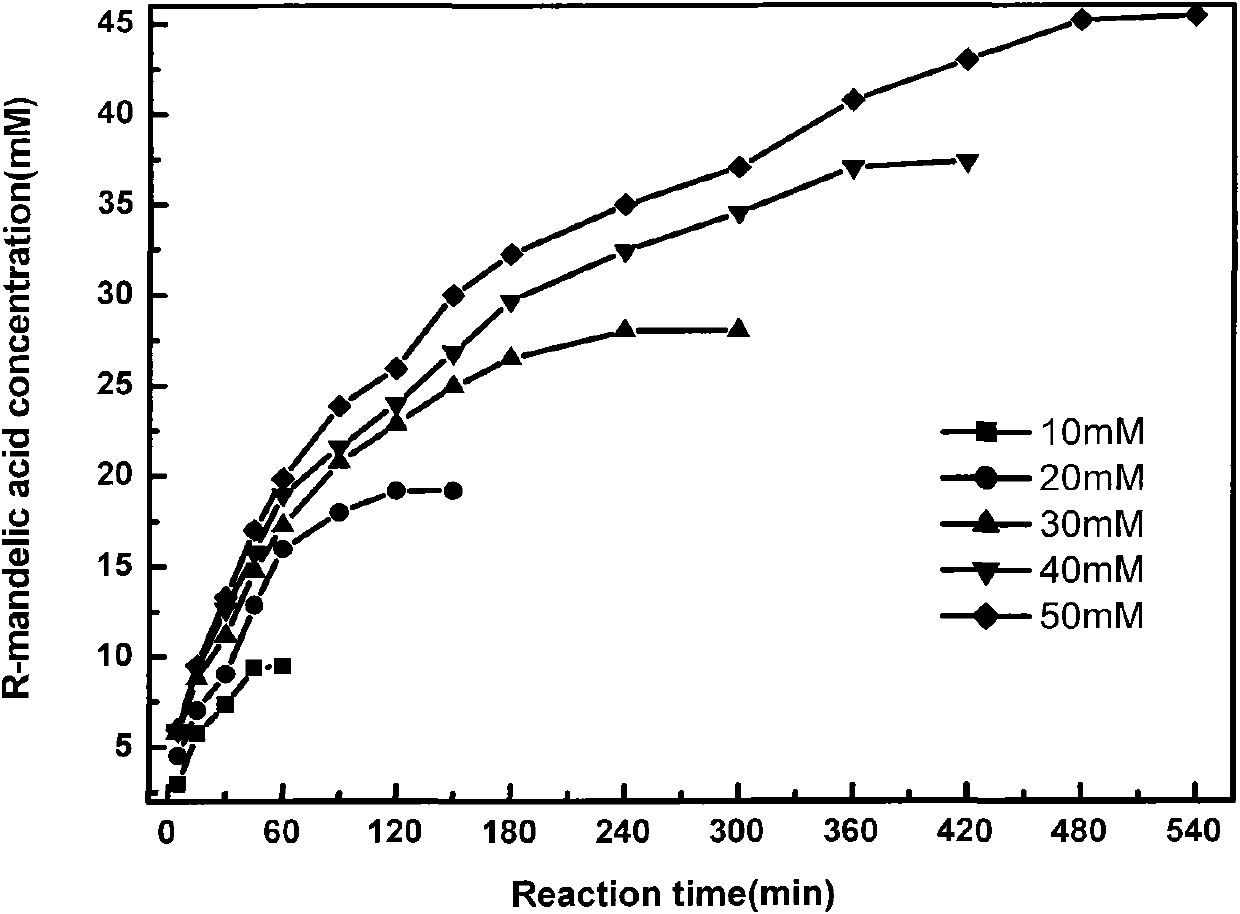

[0057] The seed solution was transferred to the optimized fermentation medium with an inoculation amount of 6% (v / v), and the liquid content in a 15L fermenter was 8L. The culture temperature was 30° C., the rotational speed was 150 rpm, and the ventilation volume was 0.4 vvm, and samples were taken to detect bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com