Method for measuring dimethyl fumarate in product by gas chromatography-mass spectrometry

A technology of dimethyl fumarate and gas chromatography is applied in the field of detection of dimethyl fumarate in products, can solve the problems of high solvent consumption and high detection cost in liquid chromatography analysis, and achieves low cost of instruments and accurate analysis methods. , the effect of less interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

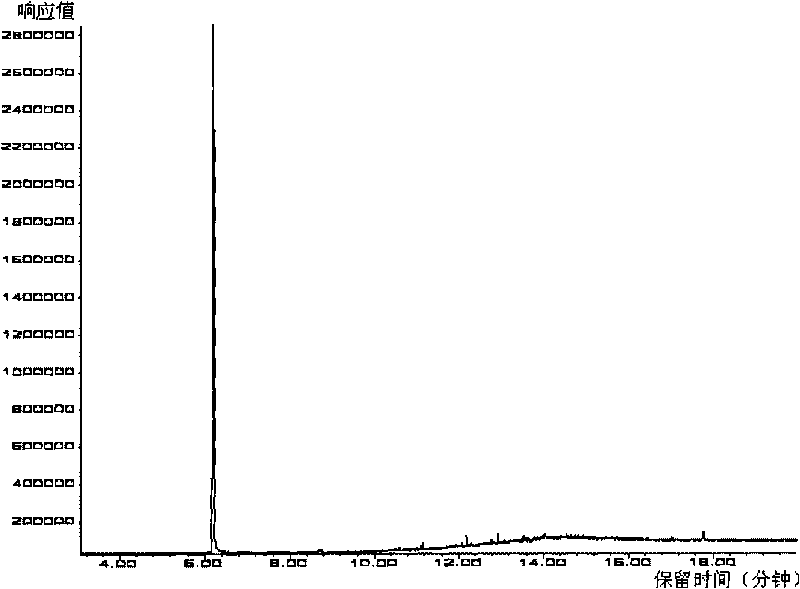

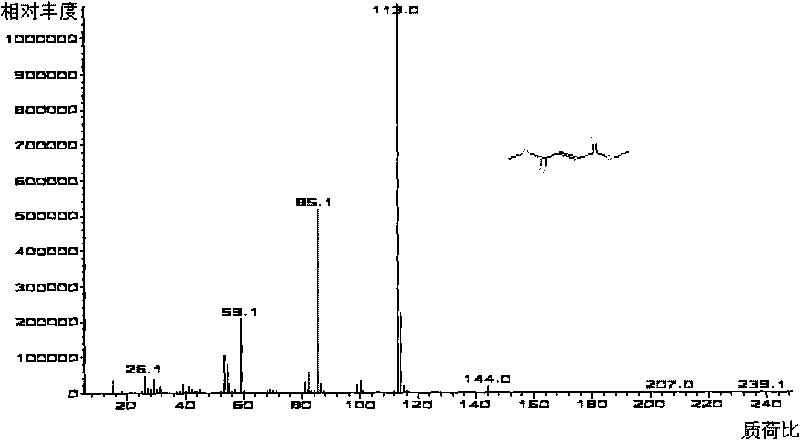

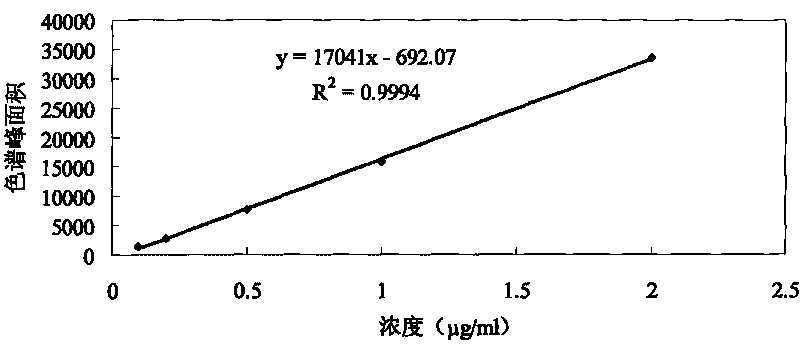

[0023] Accurately weigh 5.0mg of dimethyl fumarate, dissolve it with an appropriate amount of dehydrated ethyl acetate, transfer it to a 250ml volumetric flask, and dilute to the mark with dehydrated ethyl acetate, shake well, and stand still to obtain 20μg / ml DMF standard solution. The solution used for the test working curve of DMF was diluted step by step from the above 20 μg / ml standard solution, and prepared into a series of solutions of 0.1, 0.2, 0.5, 1.0, 2.0 μg / ml respectively, and carried out gas chromatography-mass spectrometry GC according to the above experimental conditions. -MS analysis and detection, in which the gas chromatography-mass spectrometry inlet temperature is set to 280 ° C, the interface temperature is set to 280 ° C; the carrier gas is high-purity helium, and the flow rate is 1 ml / min; the column temperature control adopts In the mode of programmed temperature rise, starting from 60°C, the temperature is raised to 100°C at a rate of 5°C / min; EI sou...

Embodiment 2

[0026] Cut the textile sample into a size of 4mm×4mm (ISO 4044:1998) with scissors, weigh about 0.5g, put it into a headspace bottle, add 5ml of dehydrated ethyl acetate extract (the sample needs to be fully shaken and wetted, and immersion in the extract), ultrasonically extract at 25°C for 30 minutes, and the working frequency of the ultrasonic instrument is 59KHZ. The ultrasonic extract was filtered with a 0.45 μm filter membrane, and the filtered extract was tested and analyzed by gas chromatography-mass spectrometry. The detection conditions of the gas chromatography-mass spectrometer were the same as in Example 1, and the external standard method was used for quantification. Three parallel samples were made on the textile sample, the test numbers were A, B, and C. The analysis results are shown in Table 1, and the first parallel sample (test number A) was measured 5 times. The analysis results are shown in Table 2. It can be seen from Table 1 that the relative standard d...

Embodiment 3

[0032]The standard solution in Example 1 was added to the prepared test solution with known negative (no target compound after testing), and the experiment was carried out according to the instrumental analysis and detection method in Example 1. Do 10 parallel measurements to the sample to get the average value, and calculate the standard recovery rate of the sample according to the actual addition amount and the actual measurement results. %, the relative standard deviation of parallel measurements was 2.14%.

[0033] Table 3 The recovery rate of the sample spiked

[0034] serial number

[0035] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com