Method for preparing monodisperse polymer nano-microspheres

A nano-microsphere and monodispersity technology, which is applied in the field of preparing monodisperse polymer nano-microspheres, can solve the problems of difficulty in ensuring the size and monodispersity of polymer microspheres, prolonging the nucleation time, and homogeneous nucleation. The size of the microspheres is easy to control, the product repeatability is good, and the effect of increasing the nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

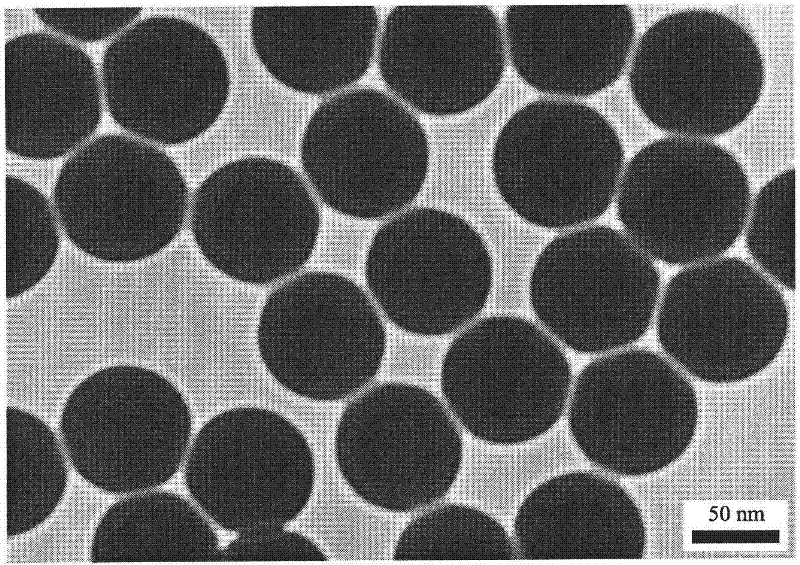

[0026] In a 250mL three-necked flask equipped with a condenser, add 96mL of deionized water and 0.17g of sodium lauryl sulfate to form a transparent solution. During stirring, 2.5 mL of styrene was added. Nitrogen was passed for 15 minutes, and the reaction system was heated to raise the temperature to 70°C. Then add 4 mL of an aqueous solution containing 0.13 g of potassium persulfate, stir at 200 rpm, and react for 4 hours to obtain monodisperse polystyrene microspheres with a diameter of 77 nm and a PDI of 1.005. Its typical scanning electron microscope pictures are as follows: figure 1 As shown, the average diameter of the microspheres is 77 nm, and the PDI is 1.005.

Embodiment 2

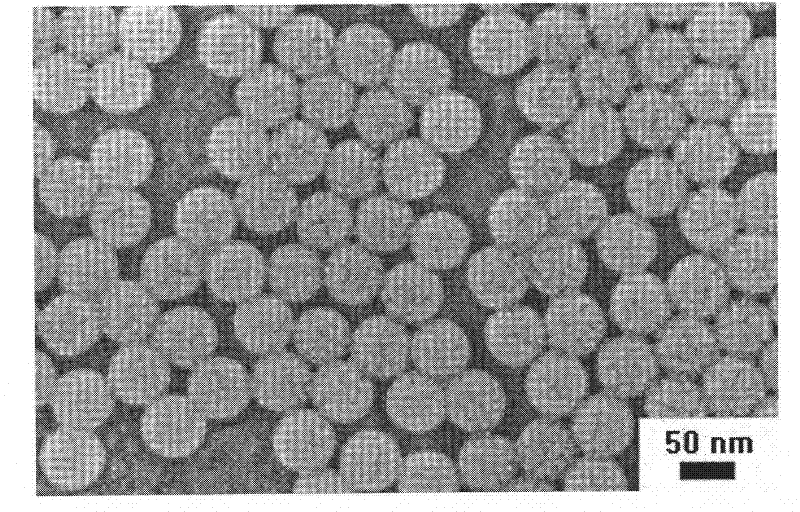

[0028] In a 250mL three-necked flask equipped with a condenser, add 96mL of deionized water and 0.09g of sodium dodecylsulfonate to form a transparent solution. During stirring, 10 mL of methyl methacrylate was added. Nitrogen was passed for 15 minutes, and the reaction system was heated to raise the temperature to 80°C. Then add 4 mL of an aqueous solution containing 0.09 g of potassium persulfate, stir at a speed of 300 rpm, and react for 3 hours to obtain monodisperse polymethyl methacrylate microspheres with an average diameter of 59 nm and a PDI of 1.01. Its typical scanning electron microscope pictures are as follows: figure 2 As shown, the average diameter of the microspheres is 59 nm, and the PDI is 1.01.

Embodiment 3

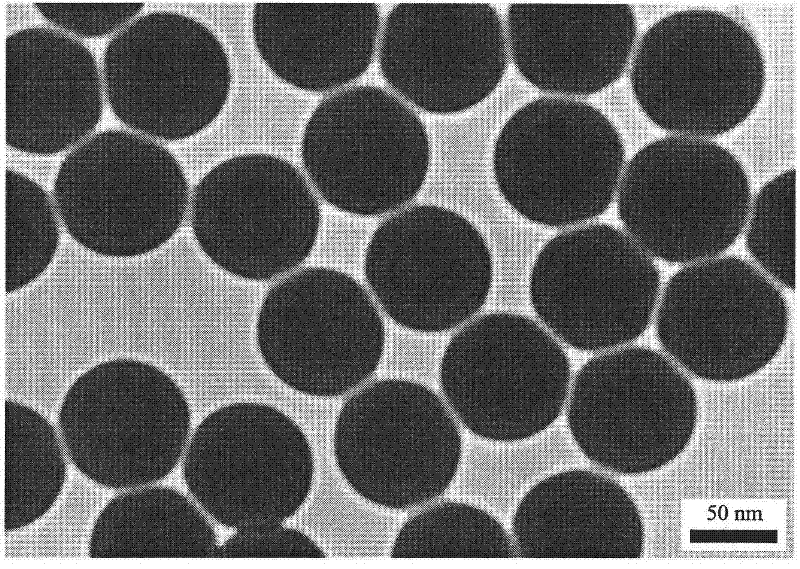

[0030] In a 250mL three-necked flask equipped with a condenser, add 71mL of deionized water, 32mL of absolute ethanol, and 0.45g of dodecyltrimethylammonium bromide to form a transparent solution. During stirring, 2.5 mL of divinylbenzene was added. Nitrogen was passed for 15 minutes, and the reaction system was heated to raise the temperature to 60°C. Then add 4 mL of an aqueous solution containing 0.13 g of ammonium persulfate, stir at 400 rpm, and react for 2 hours to obtain monodisperse polydivinylbenzene microspheres with a diameter of 61 nm and a PDI of 1.01.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com