Method for manufacturing lithium-contained composite oxide and nonaqueous secondary cell

A composite oxide and manufacturing method technology, applied in secondary batteries, non-aqueous electrolyte storage batteries, lithium storage batteries, etc., can solve problems such as cleaning effect limits, and achieve inhibition of decomposition and gas generation, storage characteristics, and charge-discharge cycle characteristics. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] (1) Manufacture of lithium-containing composite oxides

[0157] Cobalt sulfate and aluminum sulfate were added to the nickel sulfate aqueous solution to prepare a saturated aqueous solution. The content ratio of nickel, cobalt and aluminum in this saturated aqueous solution was adjusted so that the molar ratio of each element became 80:15:5. Next, it is neutralized by adding sodium hydroxide to a saturated aqueous solution to produce a ternary hydroxide Ni 0.80 co 0.15 Al 0.05 (OH) 2 precipitation. The obtained precipitate was filtered, washed with water, and then dried at 80°C.

[0158] Next, the ternary system hydroxide was heated at 600°C for 10 hours in the air to obtain the ternary system oxide Ni 0.80 co 0.15 Al 0.05 O. Then, lithium hydroxide monohydrate was added to the ternary oxide, and fired at 800° C. for 10 hours in an oxygen stream to obtain a lithium-containing composite oxide (LiNi 0.80 co 0.15 Al 0.05 o 2 ). Lithium hydroxide and lithium c...

Embodiment 2~13

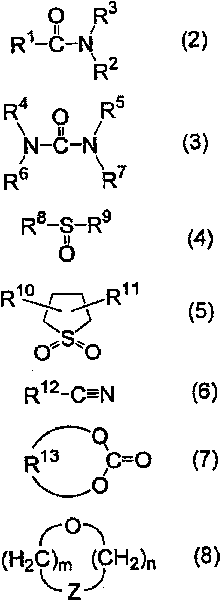

[0176] In addition to using 1000 mL of N-methylformamide (Example 2), N-methylacetamide (Example 3), N-methylpropionamide (Example 4), N,N- Dimethylformamide (Example 5), N-cyclohexylpyrrolidone (Example 6), N, N'-dimethylimidazolinone (DMI, Example 7), N, N'-dimethylene Propylurea (Example 8), Dimethylsulfoxide (DMSO, Example 9), Sulfolane (Example 10), Acetonitrile (Example 11), Propylene Carbonate (Example 12) or Dioxane Except for hexane (Example 13), a lithium-containing composite oxide and a non-aqueous secondary battery were produced in the same manner as in Example 1.

Embodiment 14

[0182] 100g of the composition formula LiNi 0.80 co 0.15 Al 0.05 o 2 The indicated lithium-containing composite oxide powder and 1000 mL of NMP were placed in a stirrer and stirred for 1 hour. After stirring, the cleaning solution was removed by filtration, and the content of the solid content was adjusted to be 95% by weight or more. Then, the lithium-containing composite oxide from which the cleaning solution was removed, 6 g of PVDF powder (manufactured by Kureha Chemical Co., Ltd.), 40 g of acetylene black, and an appropriate amount of NMP were charged into a double-arm mixer, and heated at 30° C. Stirring at the processing temperature for 30 minutes was prepared into positive electrode mixture slurry. A non-aqueous secondary battery was produced in the same manner as in Example 1 except that the positive electrode mixture slurry thus obtained was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com