Pre-wetted modified dust-free cleaning cloth and making method thereof

A technology of dust-free wiping cloth and manufacturing method, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., which can solve the problem of inability to effectively obtain and retain dirt, particle adsorption and liquid absorption effect Poor, low surface energy of dust-free wipes, etc., to reduce VOC gas release, improve adsorption and liquid absorption, and improve controllability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

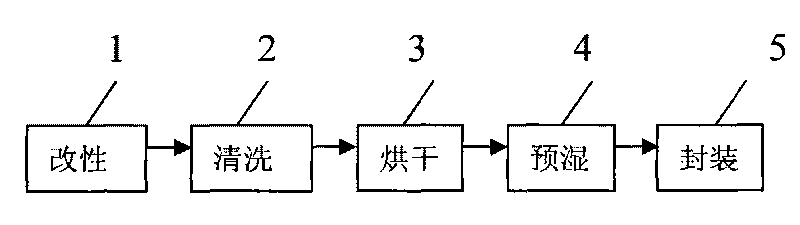

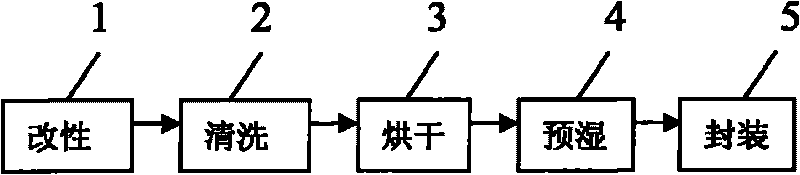

Method used

Image

Examples

Embodiment 1

[0041] Laser cut the all-polyester knitted fabric into a 7-inch-square wiping cloth, put it into an aqueous solution containing 10% modifier ethylene glycol and 0.5% catalyst zinc acetate, and the water-bath ratio is 1:20; after immersing at 90°C for 15 minutes, Wash once with ordinary water, the washing temperature is 50°C, and the washing time is 5min, then use ultrapure water for a second ultra-clean wash, and dry to obtain a dust-free wiping cloth that meets the specifications and cleanliness requirements.

[0042] In a class 10 clean room, soak the modified dust-free wiping cloth with a mixed solution of 30% deionized water and 70% isopropanol, fold and pack it in a resealable packaging bag to obtain a pre-wet modified non-toxic Dust wipes.

[0043] The pre-wet dust-free wiping cloth produced in this embodiment has good particle adsorption performance, and can remove dust particles and metal dust on the wiping surface, as well as polar organic small molecules and polymer ...

Embodiment 2

[0045] Cut 15% spandex and 85% polyester blended knitted fabric into 8-inch square wiping cloths by laser, put them in an aqueous solution containing 1% modifier propylene glycol and 1% catalyst zinc acetate, and the water-bath ratio is 1:5; at 120°C After immersing in (high-pressure hot water) for 10 minutes, wash once with ordinary water, the washing temperature is 25°C, and the washing time is 30 minutes. Dust-free wipes.

[0046] Spray the modified dust-free wiping cloth with a mixed solution of 91% deionized water and 9% isopropanol in a class 10 clean room, fold and pack it in a resealable packaging bag to obtain a pre-wet modified non-toxic Dust wipes.

[0047] The pre-wet dust-free wiping cloth produced in this embodiment has good particle adsorption performance, and can remove dust particles and metal dust on the wiping surface, as well as polar organic small molecules and polymer dirt.

Embodiment 3

[0049] 20% spandex and 80% polyester blended knitted fabric laser cut into 9 inches square wiping cloth, put into the aqueous solution containing 0.1% modifier diethylene glycol and 0.05% catalyst zinc acetate, water-bath ratio 1: 50; After immersing in 170°C (high-pressure hot water) for 1min, wash once with ordinary water at a temperature of 40°C for 15min, then use ultra-pure water for a second ultra-clean wash, and dry to obtain compliance with specifications and cleanliness Dust-free wipes as required.

[0050] Spray wet the modified dust-free wiping cloth with n-hexane in a class 10 clean room, fold and pack it in a resealable packaging bag to obtain a pre-wet modified dust-free wiping cloth.

[0051] The pre-wet dust-free wiping cloth produced in this embodiment has good particle adsorption performance, and can remove dust particles and metal dust on the wiping surface, as well as non-polar organic small molecules and polymer dirt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com