Lactoalbumin antihypertensive peptide, preparation method and application thereof

A whey protein and blood pressure-lowering peptide technology, applied in albumin peptide, application, food preparation and other directions, can solve the problem that the whey protein blood pressure-lowering peptide has not been found yet, achieve normal blood pressure without influence, and the process is simple and easy to implement and convenient. The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, preparation whey protein antihypertensive peptide

[0033]Weigh 10g of whey protein isolate, dissolve it in 200mL of water, heat in a water bath at 85°C for 20min, cool down to 40-60°C, adjust the pH to 9.0, add 30KU of alkaline protease (Novozymes), and place in a constant temperature water bath at 55 After 3 hours of hydrolysis at ℃, add papain (Beijing Xinjingke Biotechnology Co., Ltd.) 30KU, and continue to stir the enzymolysis at 60 ℃. During the enzymolysis process, the electrode of the biosensor is always inserted in the enzymolysis solution for online monitoring. The reaction was terminated when the current value on the sensor reached 3.2 μA. At this time, the enzymolysis was continued for another 3 hours, and the degree of hydrolysis of the enzymolyzed solution was determined to be 28.4%. After the reaction, heat the enzymolysis solution to 90°C, keep it for 15 minutes, inactivate the enzyme, cool it down, adjust the pH of the solution to the isoe...

Embodiment 2

[0055] Embodiment 2, preparation whey protein antihypertensive peptide

[0056] Weigh 10g of concentrated whey protein, dissolve it in 200mL of water, heat in a water bath at 85°C for 20min, cool down to 40-60°C, adjust the pH to 9.0, add 30KU of alkaline protease (Novozymes), and place in a constant temperature water bath at 50 After 3 hours of hydrolysis at ℃, adjust the pH value of the reaction solution to 7.5, add papain (Beijing Xinjingke Biotechnology Co., Ltd.) 30KU, and continue stirring at 60 ℃ for enzymolysis. In the hydrolyzate, on-line monitoring was carried out, and the reaction was terminated when the current value on the sensor reached the target value. At this time, the enzymolysis was carried out for another 2 hours, and the degree of hydrolysis of the enzymolyzate was measured to be 28.1%. After the reaction, heat the enzymolysis solution to 90°C, keep it for 15 minutes, inactivate the enzyme, cool it down, adjust the pH of the solution to the isoelectric poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

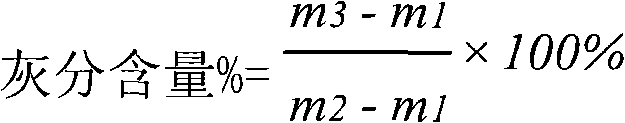

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com