Composite anode of magnesium-modified and nickel-based solid-oxide fuel cell and preparation and application thereof

A technology of solid oxide and composite anode, which is applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of low anode activity, difficult infiltration, high cost, etc., achieve uniform electrode structure distribution, improve output performance, The effect of tight interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Effect of Composite Anode of Magnesium Modified Solid Oxide Fuel Cell on Battery Performance

[0028] Nitrate co-decomposition method (magnesium nitrate and nickel nitrate decomposed at 800°C) was used to obtain magnesium-modified nickel oxide. Magnesium-modified nickel oxide (wherein Ni:Mg=1:0.01, molar ratio) is selected as the anode catalytic material, wherein 20YSZ (the molar content of yttrium oxide in YSZ is 20%) accounts for 30% (weight ratio), and the dry pressing method is adopted A 0.7 mm thick composite anode substrate was prepared and sintered at 1200° C. for 5 hours to obtain a composite anode; a layer of slurry containing YSZ with a thickness of 10 μm was coated on it. The anode / electrolyte assembly was obtained by sintering at 1450 °C for 3 h; after the LSM electrocatalyst and YSZ were mixed (50:50 by weight), the composite cathode was prepared by screen printing and sintered at 1100 °C for 5 h.

[0029] The conventional Ni-YSZ anode battery was used as ...

Embodiment 2

[0031] Effects of composite anodes for solid oxide fuel cells prepared by directly mixing magnesium oxide with nickel oxide and YSZ on battery performance

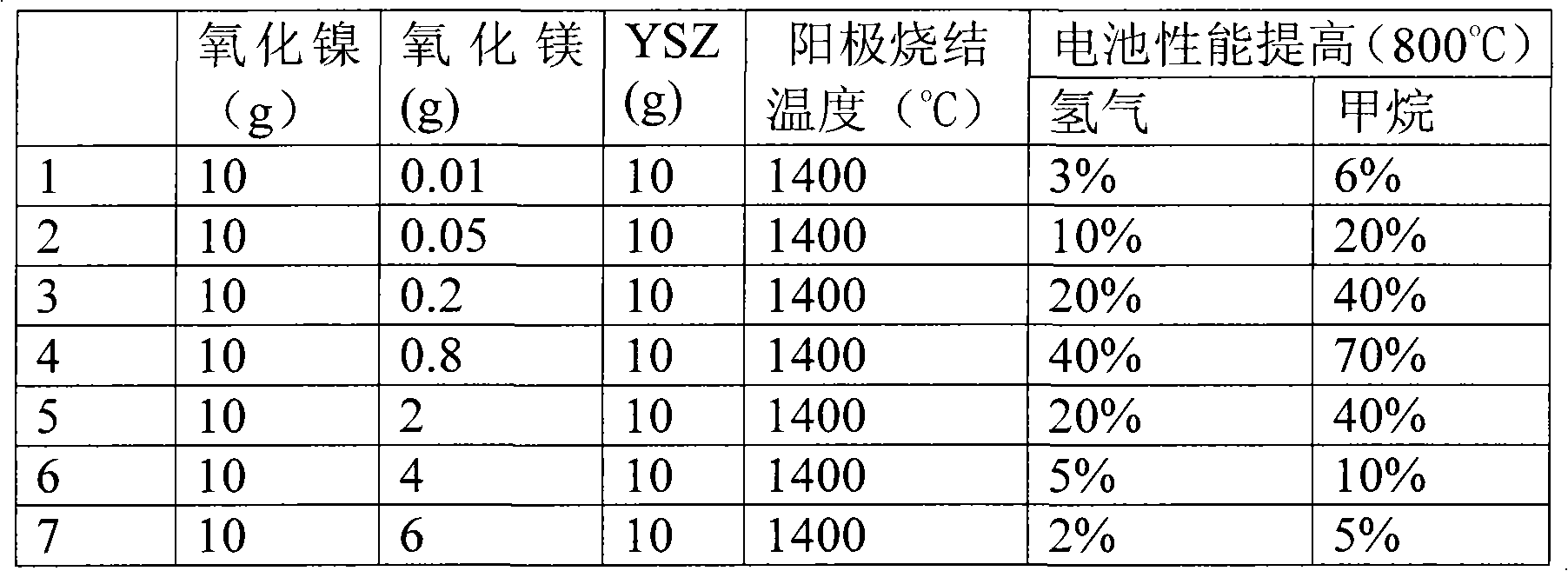

[0032] A composite anode was prepared by directly mixing magnesium oxide, nickel oxide and 8YSZ (the molar content of yttrium oxide in YSZ was 8%), and a battery was prepared. The modification results of the battery are shown in Table 1. A conventional Ni-YSZ anode battery was used as a comparison battery.

[0033] Table 1

[0034]

[0035] It can be seen from Table 1 that the battery performance gradually increases with the increase of magnesium content, but the battery performance does not improve much when the magnesium content is high.

Embodiment 3

[0037] Effect of Magnesium Modified Composite Anode on Cell Performance of Tubular Solid Oxide Fuel Cell

[0038]The method of nitrate co-decomposition (magnesium nitrate and nickel nitrate are decomposed at 800° C.) is used to obtain magnesium-modified nickel oxide. Magnesium-modified nickel oxide is used as the anode catalyst material (where Ni:Mg=1:0.04, molar ratio), mixed with 2YSZ (the molar content of yttrium oxide in YSZ is 2%) (50:50 by weight), and inorganic A tubular anode support was prepared by membrane technology, and a layer of slurry containing YSZ with a thickness of 50 μm was coated on it. After drying, it was sintered at 1600°C for 2h to obtain an anode / electrolyte assembly. After LSM electrocatalyst and YSZ were mixed (weight ratio 50:50), the composite cathode was prepared and sintered at 1200°C for 3h. The traditional Ni-YSZ anode tubular battery was used as a comparison battery. When hydrogen is used as the fuel gas, the performance of the magnesium-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com